AOI Systems for Textile Web Inspection: A Comprehensive Guide

Published on: Nov 12, 2024

Written by: Soumen das

AOI Systems for Textile Web Inspection: A Comprehensive Guide

Automated Optical Inspection (AOI) systems for textile web inspection play a vital role in modern textile manufacturing by ensuring product quality, reducing waste, and enhancing operational efficiency. Textiles, including fabrics, non-woven materials, and knitted goods, are produced in continuous rolls or webs. An AOI system for textile web inspection is designed to detect defects such as holes, stains, irregular patterns, and color variations across these continuous surfaces in real-time.

What Is an AOI System for Textile Web Inspection?

An AOI (Automated Optical Inspection) system is a high-tech solution that combines imaging sensors, lighting, and machine vision algorithms to inspect textile surfaces continuously. In textile manufacturing, these systems are set up along the production line to capture high-resolution images of the moving textile web, analyze them for defects, and provide immediate feedback to operators. AOI systems are programmed to recognize defects based on predefined criteria, ensuring that only high-quality materials proceed down the line.

Textile AOI systems can be tailored for different types of textiles, from delicate fabrics to heavy-duty industrial materials, making them versatile for various applications.

How AOI Systems Work in Textile Inspection

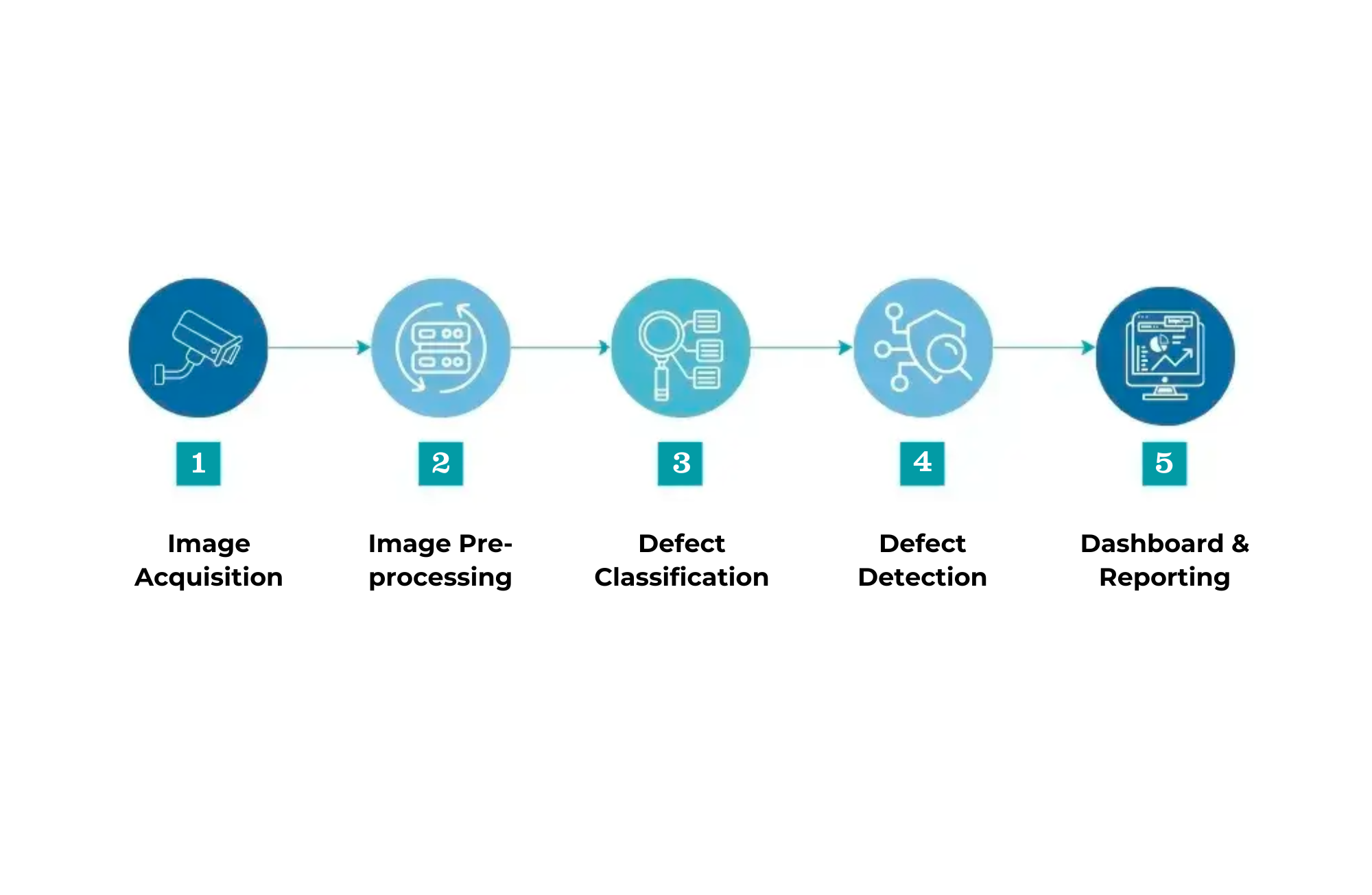

Step 1: Image Acquisition

-

The fabric moves continuously under the inspection system.

-

Cameras capture high-resolution images of the fabric surface.

-

Lighting systems ensure defects are visible and images are clear.

Step 2: Image Processing

-

Captured images are transferred to the processing unit.

-

Pre-processing steps, such as noise reduction and contrast enhancement, are applied.

Step 3: Defect Detection

-

Machine vision algorithms analyze images to identify anomalies.

-

Techniques like edge detection, texture analysis, and pattern recognition are employed.

-

AI models trained on defect samples improve detection accuracy and reduce false positives.

Step 4: Defect Classification

-

Detected defects are classified based on type, size, and severity.

-

Common classifications include holes, stains, misweaves, and color inconsistencies.

Step 5: Reporting and Action

-

The system logs defects with their exact location on the fabric.

-

Alerts are sent to operators, and defects can be marked or removed from the production line.

-

Data is stored for quality control analysis and continuous improvement.

Key Components of an AOI System for Textile Inspection

High-Resolution Imaging System:

The imaging system, typically composed of line-scan or area-scan cameras, captures detailed images of the textile web. Line-scan cameras are ideal for continuous inspection as they capture each line of the moving textile at high speed, creating a seamless image of the web. The choice of camera depends on factors like web speed, textile width, and defect size requirements.

Lighting System:

Proper lighting is crucial in textile inspection. Uniform lighting, such as LED or diffused light sources, ensures that each area of the textile is equally illuminated, allowing the camera to capture accurate details. Different lighting configurations, like backlighting or side lighting, may be used based on the texture and reflectivity of the textile to enhance defect visibility.

Machine Vision Algorithms:

The core of the AOI system lies in its software, which uses machine vision algorithms to detect and classify defects. These algorithms analyze the captured images for specific patterns or anomalies, comparing them to preset standards. Some AOI systems also incorporate AI and machine learning, allowing them to improve their accuracy by learning from detected defects over time.

Defect Classification and Reporting Software:

Once a defect is detected, the AOI system’s software classifies it based on severity, location, and type, such as holes, stains, or texture irregularities. This data is then logged in reports that operators can review for quality analysis and process improvement.

Real-Time Feedback and Integration with Manufacturing Systems:

AOI systems can be integrated with the production line, allowing for real-time alerts and automated responses. When a defect is detected, the system can either alert the operator to manually remove or fix the issue or automatically divert the defective section for reinspection.

Types of Defects Detected in Textile Web Inspection

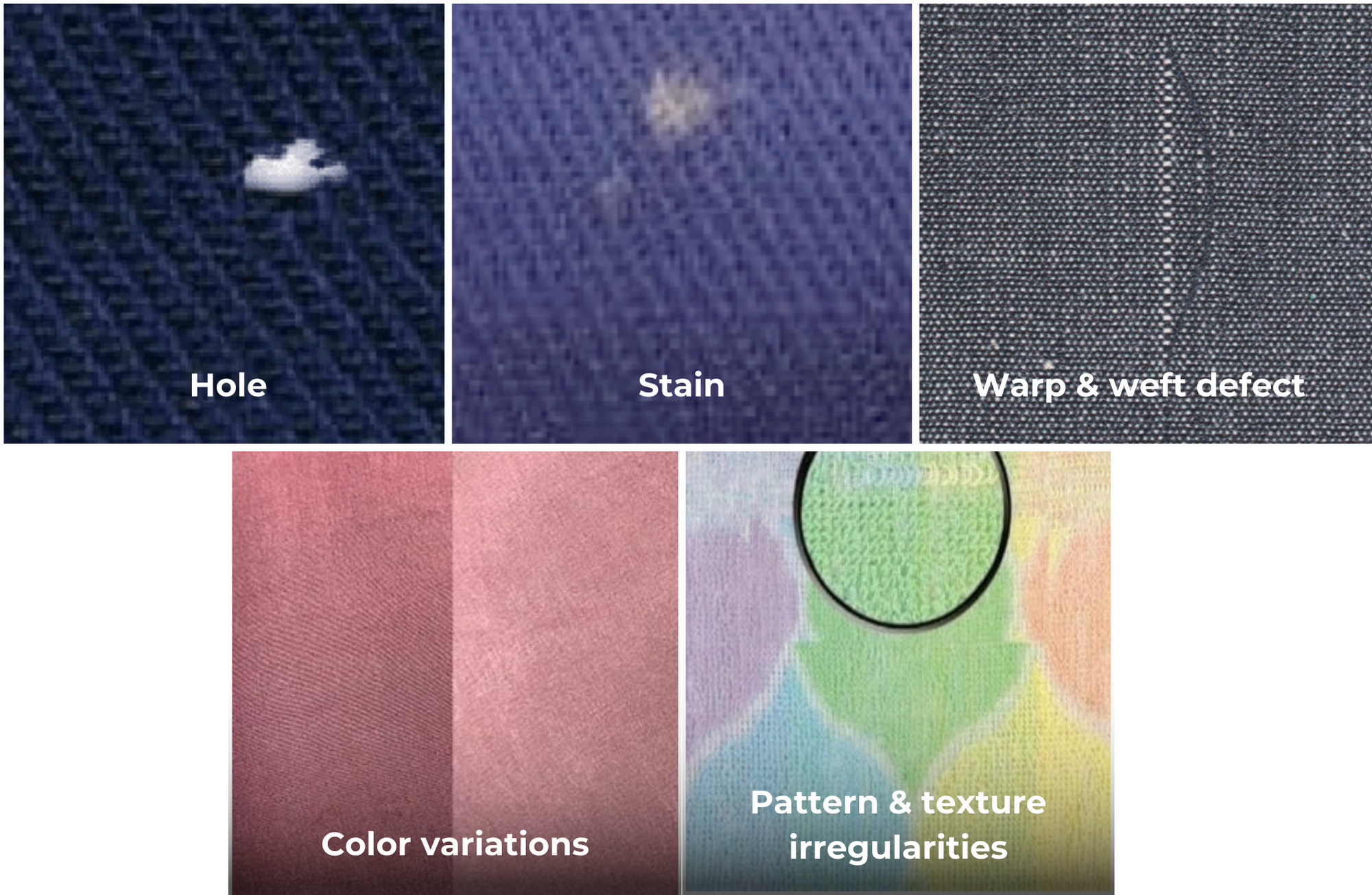

Holes and Tears:

Small holes and tears can appear due to machine wear or fabric inconsistencies. These are critical defects as they affect the structural integrity of the textile.

Color Variations:

In textiles, color consistency is crucial for aesthetic and quality standards. AOI systems detect even subtle color deviations across the web, which may occur due to dyeing or printing inconsistencies.

Stains and Contaminants:

Foreign particles, stains, or oil spots on the fabric are common issues. AOI systems can identify and classify these contaminants, ensuring that only clean textiles reach the end product.

Pattern and Texture Irregularities:

Fabrics with patterns, such as weaves or knits, can suffer from irregularities in the alignment or design of these patterns. AOI systems are adept at detecting variations in texture and pattern that are not easily visible to the human eye.

Warp and Weft Defects:

In woven fabrics, the alignment of warp (lengthwise threads) and weft (crosswise threads) is crucial. AOI systems detect deviations in thread alignment or density, preventing defects like misaligned patterns or uneven surfaces.

Key Technologies Used in AOI Systems for Textile Inspection

Machine Learning and Artificial Intelligence:

Advanced AOI systems use AI and machine learning to improve defect detection accuracy. By training on vast datasets, these systems learn to recognize subtle patterns and continuously refine their algorithms, enabling them to detect new types of defects more effectively.

High-Speed Line-Scan Cameras:

Line-scan cameras are essential for continuous inspection of moving textiles. They provide high-resolution images of every part of the web as it moves beneath the camera, allowing for detailed inspection without slowing down production.

Infrared (IR) and Ultraviolet (UV) Imaging:

Some AOI systems use IR or UV light sources to detect defects that are not visible under regular lighting. For example, IR imaging can highlight imperfections in darker fabrics, while UV light can reveal stains or foreign particles.

Edge Detection and Pattern Recognition Algorithms:

Edge detection algorithms help to identify boundaries and structural features in patterned textiles, making it easier to detect alignment issues or misaligned patterns. Pattern recognition algorithms further enhance detection accuracy for intricate designs.

Implementation Considerations for AOI Systems in Textile Manufacturing

Optimizing Camera and Lighting Setup:

The quality of inspection depends heavily on the placement and quality of the cameras and lighting. Lighting should be configured to minimize shadows and reflections, especially on reflective or textured fabrics. Camera resolution should be chosen based on the smallest defect size that needs to be detected.

Regular Calibration and Maintenance:

AOI systems require regular calibration to ensure accuracy, especially in high-speed textile environments where environmental factors can impact imaging. Cleaning lenses, adjusting lighting, and recalibrating sensors are essential maintenance tasks for consistent performance.

Integration with Existing Production Systems:

AOI systems are most effective when integrated into the manufacturing process control system. This allows for real-time responses, such as diverting defective textiles or adjusting production parameters based on inspection data.

Setting Thresholds and Standards:

Defining acceptable defect thresholds and quality standards is crucial for effective inspection. Manufacturers can program the AOI system to classify defects by severity, ensuring only defects above a certain threshold trigger an alert or intervention.

Advantages of AOI Systems in Textile Web Inspection

Enhanced Quality Control:

AOI systems ensure consistent quality by detecting defects in real-time. This reduces the likelihood of defective materials reaching later stages of production or the customer, safeguarding brand reputation and customer satisfaction.

Reduced Waste:

By identifying defects early in the production process, AOI systems minimize waste. Defective sections of fabric can be corrected or removed before they are processed further, saving valuable materials and resources.

Increased Production Efficiency:

AOI systems work at high speeds, allowing them to keep up with rapid textile production lines. This automation reduces the need for manual inspection, enabling manufacturers to produce high volumes without compromising on quality.

Objective and Repeatable Results:

Unlike human inspectors, AOI systems provide objective, repeatable results, free from fatigue or subjective bias. This consistency improves the reliability of the inspection process and allows for accurate quality benchmarking.

Data-Driven Decision Making:

The detailed reports generated by AOI systems allow manufacturers to analyze defect trends and make data-driven improvements. By identifying recurring issues, manufacturers can address root causes and implement process improvements.

Challenges in Textile Web Inspection with AOI Systems

Variation in Fabric Types and Textures:

Textiles come in various materials and textures, each requiring specific inspection parameters. For example, inspecting delicate silk differs significantly from inspecting heavy-duty industrial textiles. AOI systems must be configured or adjusted for each type to ensure optimal inspection.

Complex Patterns and Designs:

Patterned or complex designs, such as those found in jacquard fabrics or intricate knits, can challenge even the most advanced AOI systems. Machine learning and adaptive algorithms are crucial in these cases to distinguish between intentional patterns and defects.

Dynamic Changes in Production Speed:

Textile manufacturing processes can involve varying speeds, which can affect image quality and detection accuracy. High-speed cameras and precise synchronization with production lines are necessary to maintain accurate inspections.

Best Practices for Maximizing AOI System Effectiveness

- Regular Calibration: Ensure imaging devices are calibrated for consistent performance.

- Maintenance Schedules: Keep equipment clean and serviced to prevent degradation.

- Data Management: Securely store and backup inspection data for analysis.

- Continuous Learning: Update AI models with new defect data to improve accuracy.

- Operator Training: Educate staff on system capabilities and troubleshooting.

AOI systems for textile web inspection are transforming the textile manufacturing industry by automating quality control and ensuring consistent, defect-free products. These systems provide unparalleled accuracy and efficiency, detecting and classifying defects that would be challenging or impossible to identify through manual inspection. With benefits including enhanced quality control, reduced waste, and increased productivity, AOI systems are an invaluable asset for textile manufacturers seeking to maintain high-quality standards.

By leveraging advanced imaging technologies, machine learning, and robust defect detection algorithms, AOI systems enable textile manufacturers to meet customer expectations and regulatory requirements while maximizing operational efficiency. As technology continues to advance, AOI systems will become even more adaptable, accurate, and essential to the textile industry’s quality control processes.