What is a web inspection system?

Published on: Nov 11, 2024

Written by: Soumen das

Web Inspection System

A web inspection system is a powerful inspection system that is used in various industries to monitor and assess the quality of continuous material surfaces, such as plastic films, paper, metal foils, textiles, and more. This system identifies defects in real-time, ensuring quality control, minimizing waste, and enhancing productivity. Here’s a detailed guide covering its core principles, components, and benefits:

Introduction to Web Inspection Systems

In manufacturing, ensuring the quality of products produced in continuous rolls or webs is essential for maintaining industry standards and customer satisfaction. Traditional inspection methods are often time-consuming, prone to errors, and limited in scope. Web inspection systems provide an automated, efficient, and accurate solution by using advanced imaging technology to detect surface defects as the material moves through the production line.

Key Components of a Web Inspection System

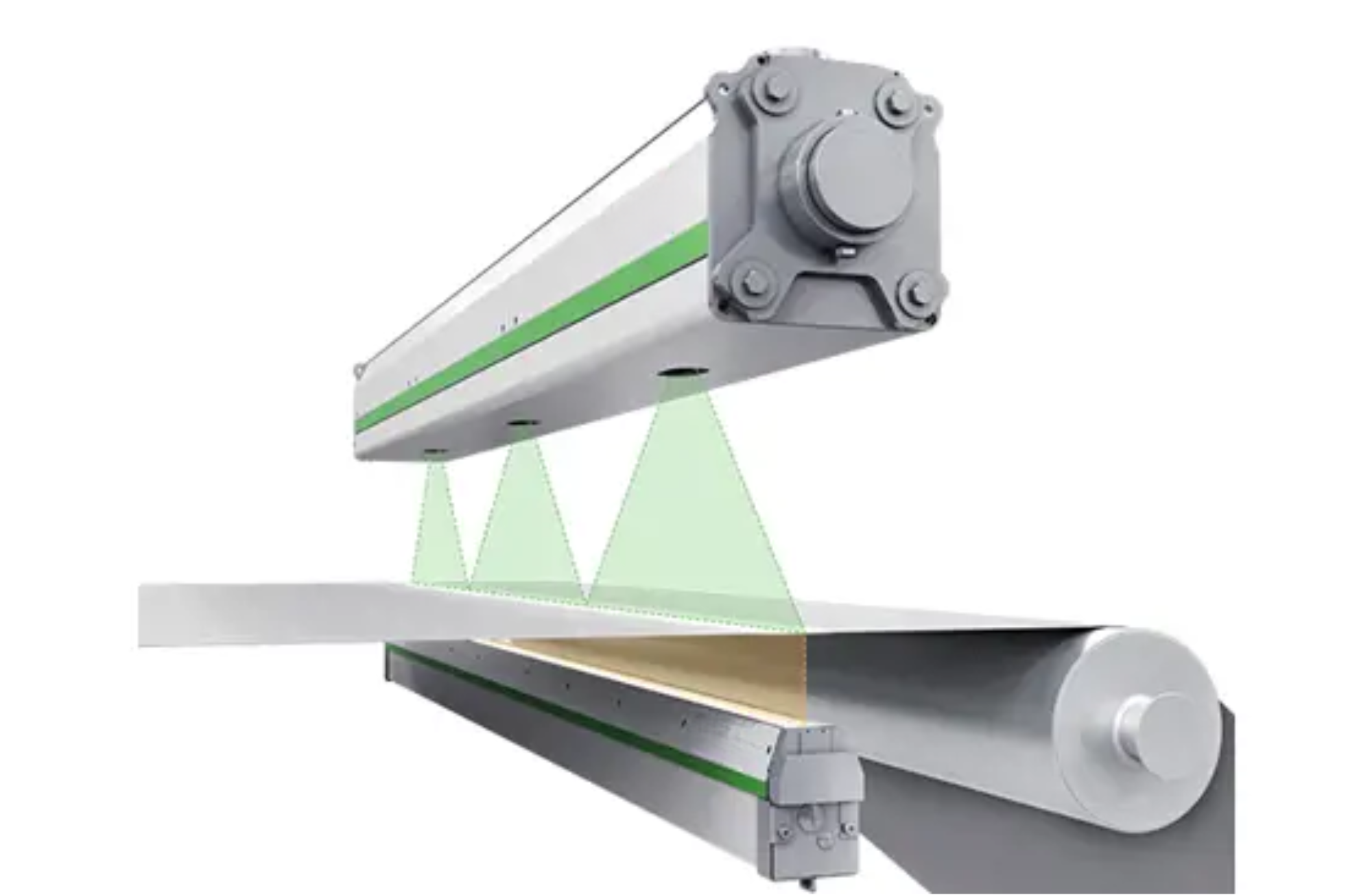

Imaging Device:

- The imaging device, often a high-resolution camera or CIS (Contact Image Sensor), captures detailed images of the material surface.

- These cameras are strategically positioned to cover the entire web width and can include features like line-scan technology, capturing data line-by-line as the material moves beneath the camera.

Illumination System:

- Proper lighting is critical for capturing high-quality images. The illumination system usually consists of LED or other light sources placed in a way that minimizes reflections and enhances defect visibility.

- Different materials require specific lighting configurations to highlight certain defect types, such as scratches, stains, or pinholes.

Processing Unit:

- Equipped with high-speed processors and specialized software, the processing unit analyzes the images in real-time to detect and classify defects.

- Using machine vision and AI algorithms, the system compares images against a standard quality reference, identifying deviations that indicate defects.

Software and User Interface:

- The software provides an interface where operators can monitor, review, and respond to defects detected on the web.

- Advanced software allows for defect classification, visualization, and reporting, helping users make data-driven decisions to enhance quality.

Alarm and Feedback System:

- If a defect is detected, the system can trigger an alarm, stop the production line, or mark the defective area for further inspection, depending on the defect's severity.

- Some systems also offer closed-loop feedback to the production line, enabling real-time adjustments to minimize future defects.

Working Principle of a Web Inspection System

The process of web inspection generally involves the following steps:

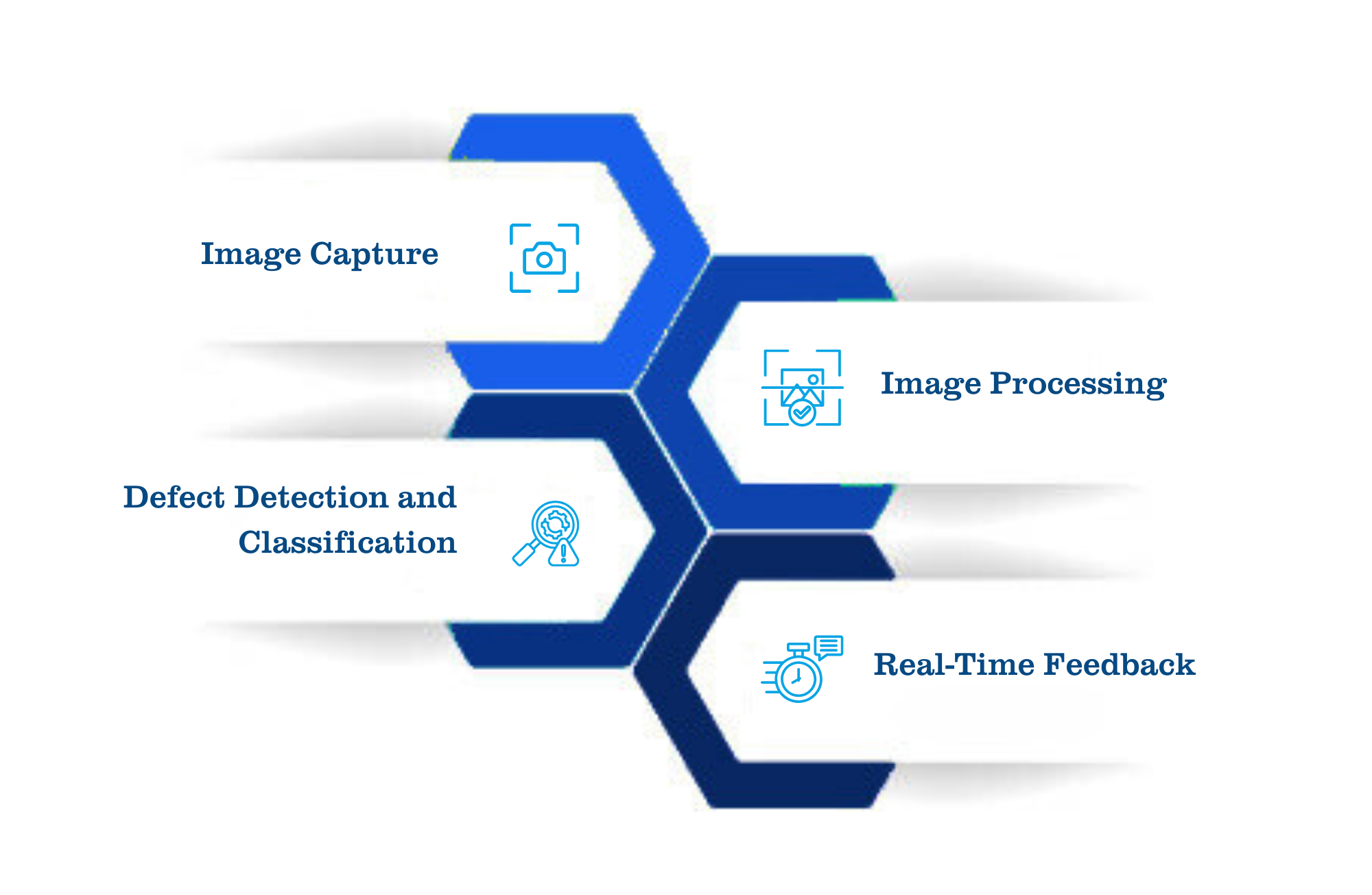

Image Capture:

- As the material moves along the production line, the camera captures high-resolution images at rapid speeds.

Image Processing:

- Captured images are analyzed frame by frame to identify potential defects. This process involves filtering, enhancing, and segmenting the images to isolate areas of interest.

Defect Detection and Classification:

- The processed images are then analyzed using algorithms that recognize patterns associated with specific defects.

- Machine learning models trained on known defects can classify these defects into categories, such as scratches, bubbles, wrinkles, or contamination.

Real-Time Feedback:

- Once a defect is detected, the system instantly alerts the operator. In advanced systems, feedback loops adjust process parameters in real-time to correct the issue before the defect recurs.

Types of Defects Detected by Web Inspection Systems

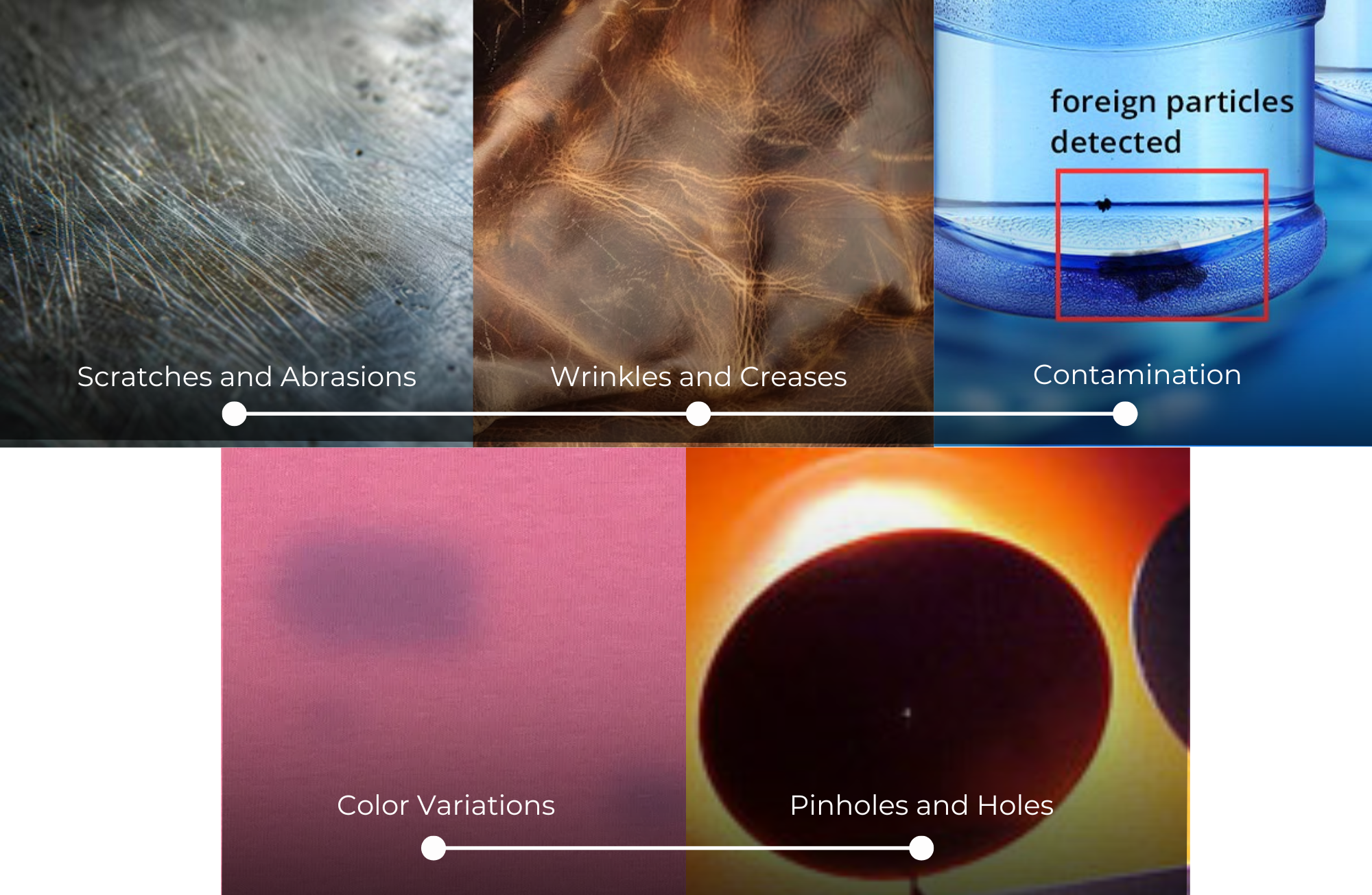

Web inspection systems can identify a variety of defects, depending on the application and the material inspected. Common defects include:

- Scratches and Abrasions: Often caused by mechanical contact, these defects impact the material's surface quality.

- Wrinkles and Creases: Structural defects that can affect the material’s performance in later stages of production.

- Contamination: Foreign particles or dust can become embedded in the material, compromising its quality.

- Color Variations: Color shifts can occur due to inconsistent material processing, often seen in textiles or printed materials.

- Pinholes and Holes: Common in films and foils, these defects are critical in packaging applications where material integrity is essential.

Advanced Features of Modern Web Inspection Systems

- Machine Learning and Artificial Intelligence (AI):

- AI algorithms can learn from previous data, improving defect detection and classification over time. They can recognize new defect patterns and adjust parameters dynamically.

- Automated Reporting and Analysis:

- Modern systems log defect data for quality analysis, creating reports that provide insights into recurring defect types, frequencies, and locations. This data helps in continuous process improvement.

- Integration with Manufacturing Execution Systems (MES):

- By integrating with MES, web inspection systems provide real-time quality data, helping manufacturers make informed decisions to optimize production.

- Remote Monitoring and Control:

- Some systems offer remote access, enabling operators to monitor production quality from anywhere, allowing for swift responses to issues, even when off-site.

Applications of Web Inspection Systems

Web inspection systems are used in a wide range of industries, including:

- Plastic Film and Foil Manufacturing: For detecting pinholes, scratches, and contamination.

- Textile Industry: For identifying color variations, wrinkles, and pattern inconsistencies.

- Printing and Packaging: For quality control in printed materials, detecting color shifts, alignment issues, and smudges.

- Metallurgy: For inspecting metal sheets and foils, identifying scratches, holes, and thickness inconsistencies.

Intelgic’s Customized Web Inspection System

Intelgic specializes in providing comprehensive, tailored web inspection solutions for complex inspection automation across diverse manufacturing environments. Our advanced web inspection systems integrate CIS (Contact Image Sensors) or machine vision imaging technologies, chosen based on the specific requirements of each application.

CIS Imaging for Precision Surface Inspection:

Machine Vision Imaging Solutions:

For more complex inspection needs, Intelgic’s machine vision systems utilize high-resolution cameras paired with sophisticated lighting setups, enhancing defect visibility. The system’s machine vision algorithms process images in real-time to detect and classify defects such as scratches, creases, and contamination, regardless of material type or production speed.

Customizable Software and Real-Time Feedback:

Intelgic’s software suite offers a user-friendly interface for monitoring quality in real-time, alerting operators to anomalies and providing immediate feedback to the production line. The software is fully customizable, allowing it to adapt to the unique specifications of each manufacturing process.

Seamless Integration and Continuous Improvement:

Our web inspection systems are designed to integrate seamlessly into existing production lines, enhancing inspection without disrupting workflow. With built-in machine learning capabilities, Intelgic’s systems learn from historical data, enabling continuous improvement in defect detection and inspection accuracy.

Intelgic’s web inspection solutions empower manufacturers to uphold stringent quality standards, reduce waste, and improve operational efficiency, ensuring that every product meets the highest level of precision and quality.

Web inspection systems are a vital tool in modern manufacturing environments. By providing real-time monitoring and high-precision defect detection, these systems help manufacturers maintain high-quality standards, reduce waste, and boost efficiency. With advancements in AI and machine learning, web inspection systems are becoming more intelligent, adaptive, and capable of handling even the most complex quality challenges.

As industries continue to demand higher quality standards, investing in a robust web inspection system becomes crucial for manufacturers looking to stay competitive in a quality-driven market.