Product counting: small object counting

Published February 20, 2024

Traditional methods of product and other objects counting, often manual and labor-intensive, are fraught with potential for error, leading to inventory discrepancies, operational delays, and financial losses. On the other hand, the old school counting machines are expensive, slow and prone to errors. The Vision AI solved these problems. AI is emerging as a revolutionary solution, transforming the way objects are counted, tracked, and managed across sectors such as manufacturing, supply chain and logistics. The impact of Vision AI on object counting within manufacturing, supply chain, and logistics is significant in recent days.

The Emergence of Vision AI in Object Counting

Vision AI leverages advanced algorithms and machine learning models to interpret and analyze video footage and images coming from cameras, installed in production lines, assembly lines, counting stations or some other areas. In the context of manufacturing and logistics, it can identify, count, and categorize objects with unprecedented speed and accuracy. This capability not only streamlines inventory management but also enhances operational efficiency and data accuracy throughout the supply chain.

The AI is capable of counting even tiny objects accurately as it happens. You can add this counting information into your business management software for reports and to help make decisions.

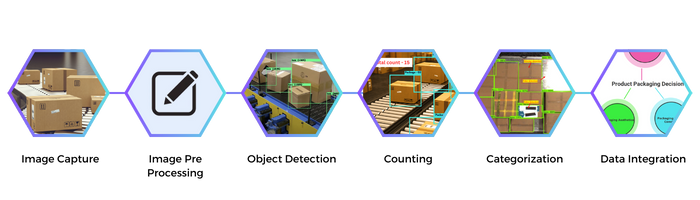

How vision AI counts objects like products and packets

Here’s a simplified overview of how it works:

Image Pre Processing: captured images are processed to enhance quality and prepare them for analysis. This step might include adjusting brightness, contrast, or filtering out irrelevant parts of the image to focus on

Object Detection: The processed images are then analyzed by the AI to identify specific objects. This is done using pre-trained models that have learned what different products and packets look like from thousands, if not millions, of examples. The AI uses patterns, shapes, colors, and other features to recognize objects.

Counting: Once objects are detected, the AI counts them by keeping track of each identified item. For moving objects on a conveyor belt, for example, the system can track each item's movement to ensure it's only counted once.

Categorization: In addition to counting, Vision AI can also categorize objects based on their features. For instance, it can differentiate between different types of products or packets and count them separately.

Data Integration: The counting and categorization data generated by the AI can then be integrated into an ERP (Enterprise Resource Planning) system. This allows for real-time inventory tracking, reporting, and analysis, which aids in decision-making processes.

Counting smaller objects with high accuracy

Counting smaller objects with high accuracy using Vision AI involves several sophisticated techniques and technologies that enhance the precision and reliability of the counting process.

High-Resolution Cameras

To accurately count small objects, high-resolution cameras are employed to capture detailed images where even the smallest features are visible. These cameras ensure that each object can be distinctly identified, no matter its size.

Advanced Image Processing

After capturing the images, advanced image processing algorithms enhance the visuals to make the small objects more distinguishable. Techniques such as contrast enhancement, noise reduction, and edge detection are used to improve the quality of the image and highlight the features of the objects.

Deep Learning Models

Vision AI utilizes deep learning models, particularly Convolutional Neural Networks (CNNs), trained on vast datasets of images to recognize and differentiate objects. These models are adept at handling the complexity of identifying small objects within a dense or cluttered background by learning from the features and patterns specific to the objects of interest.

Object Detection and Segmentation

For accurate counting, the AI system not only detects objects but also segments them, distinguishing each individual item even when they are close together or overlapping. Object detection algorithms can accurately identify the boundaries of each object, ensuring each one is counted once.

Real-Time Processing

Vision AI systems are capable of processing images in real-time, allowing for the immediate counting of objects as they are detected. This is crucial for environments where objects need to be counted on the fly, such as on a production line.

Integration with Data Systems

The accurate count of small objects is then integrated into data management or ERP systems. This integration allows businesses to use the counting data for inventory management, decision-making, and reporting purposes, ensuring that the information is utilized effectively across the organization.

Continuous Learning and Improvement

Vision AI systems can continue to learn and improve over time. As more data is collected and analyzed, the AI models can be fine-tuned to increase accuracy and adapt to new types of objects or changes in the environment.

Use cases of object counting in manufacturing, supply chain and logistics

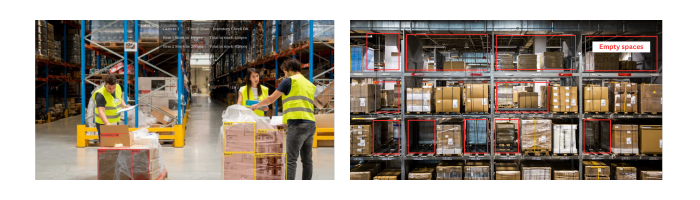

Inventory Management

- Real-time Stock Counts: In warehouses and distribution centers, Vision AI facilitates the real-time counting of stock as it arrives, is stored, and leaves the facility. This accuracy in counting helps maintain correct inventory levels, reducing overstock or stockouts.

- Shelf Stock Monitoring: Retailers can use Vision AI to monitor shelf stock in real-time, ensuring shelves are well-stocked and inventory levels are maintained accurately, enhancing customer satisfaction.

Order Fulfillment and Packaging

- Order Accuracy: Vision AI systems ensure that orders are fulfilled with the correct number of items, improving customer satisfaction and reducing returns.

- Packaging Integrity: Before shipping, Vision AI can count and confirm that all parts of an order are included in the package, ensuring complete orders are sent to customers.

Supply Chain Optimization

- Load Optimization: Vision AI helps in optimizing how goods are loaded into containers or trucks by accurately counting and assessing the size and volume of packages. This maximizes space utilization and can reduce shipping costs.

- Customs and Compliance: By providing accurate counts and documentation of goods, Vision AI aids in smoother customs clearance for international shipments, ensuring compliance with import/export regulations.

Safety and Loss Prevention

- Theft and Loss Reduction: Accurate, real-time counts help identify discrepancies quickly, reducing opportunities for theft and loss within the supply chain.

- Hazardous Material Handling: For industries dealing with hazardous materials, Vision AI can count and track materials without human intervention, reducing safety risks.

Data-Driven Decision Making

- Trend Analysis and Forecasting: With accurate, up-to-date counts, companies can analyze trends, predict demand, and make informed decisions on production and inventory levels.

- Waste Reduction: By optimizing production and inventory levels based on accurate counts, companies can reduce waste and improve sustainability.

Return Processing

- Efficient Return Handling: Vision AI can quickly count and categorize returned items, streamlining the return process and reintegrating products into inventory more efficiently.

The integration of Vision AI into object counting within manufacturing, supply chain, and logistics industries marks a significant leap forward in operational efficiency, accuracy, and data management. By automating and optimizing counting tasks, businesses can reduce errors, lower operational costs, and improve decision-making, ultimately enhancing competitiveness in a global market. As technology advances, the potential for Vision AI to further revolutionize these industries is vast, promising even more sophisticated solutions to the complex challenges of today's fast-moving economic landscape.