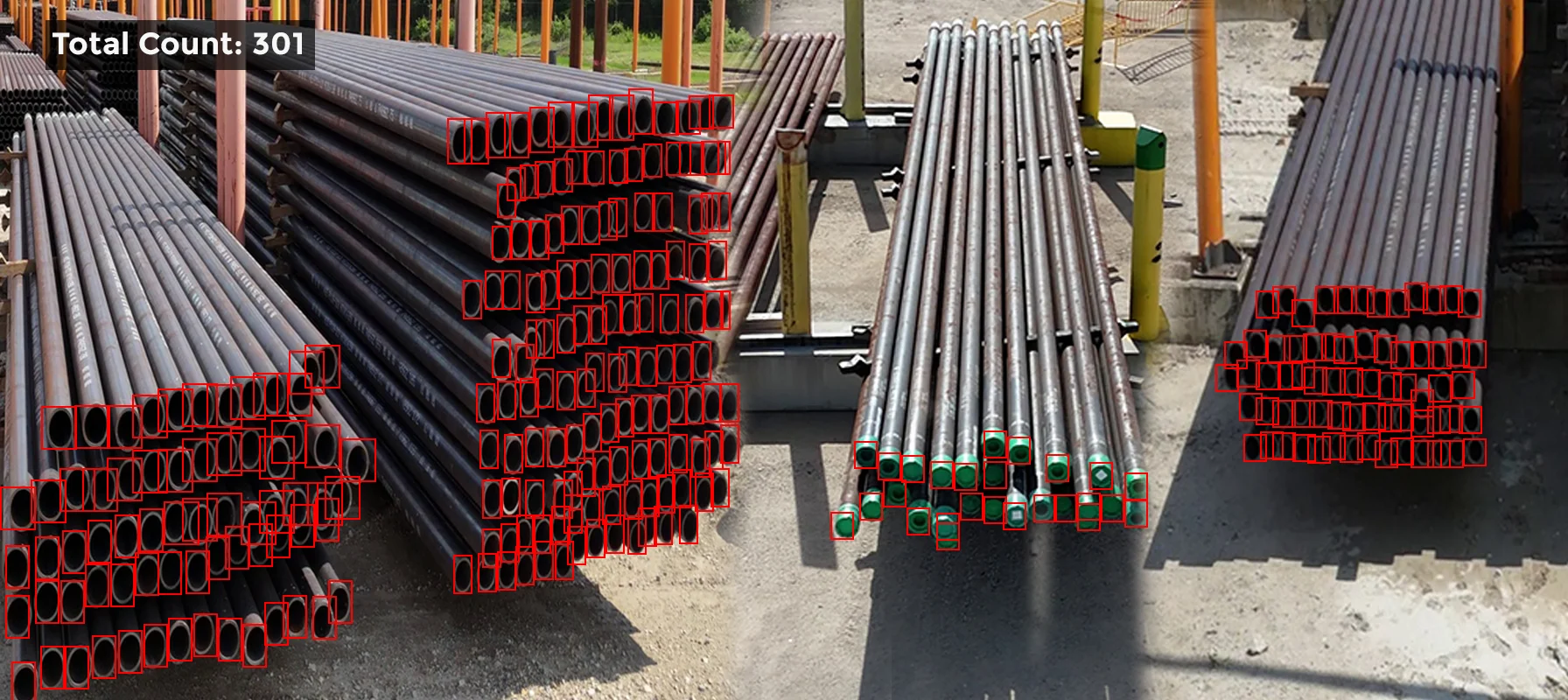

Our client, one of the largest pipe manufacturers globally, operates a big facility in Texas, USA. With hundreds of racks in an open yard warehouse, they manually counted pipes for auditing and tracking purposes using drone footage. The manual counting process was time-consuming, labor-intensive, and prone to errors. The client sought an automated solution to enhance accuracy and efficiency.

The primary goal was to develop an automated system to count pipes accurately using drone footage and display the results on a dashboard. Additionally, the system needed to provide a downloadable spreadsheet of the counting data and integrate with the client's ERP system in future phases.

The successful POC paved the way for integrating the counting system with the client's ERP, enabling end-to-end automation of the pipe tracking and auditing process. Future enhancements will focus on improving AI model accuracy under even more varied conditions and expanding the system’s capabilities to other parts of the facility.

This case study demonstrates the potential of AI-driven solutions in transforming manual, error-prone processes into efficient, automated systems. Our flexible and robust pipe counting system not only met the client’s immediate needs but also set the stage for further technological integration and process automation.

©2025 Intelgic Inc. All Rights Reserved.