Drilled and Threaded Holes in Large Parts Inspection

Published on: Jan 22, 2025

Written by: Content team, Intelgic

Large Parts Inspection for Drilled and Threaded Holes Using Machine Vision

In industries like aerospace, automotive, heavy machinery, and oil and gas, large parts are integral to manufacturing and assembly processes. Among the critical quality control tasks in these industries is the inspection of drilled or threaded holes in large components. Precision is paramount as even minute deviations can lead to compromised functionality, safety risks, or failures in final assembly. Machine vision technology, with its capability for micron-level accuracy, is revolutionizing the inspection of drilled and threaded holes in large parts.

This article explores how advanced machine vision systems inspect large parts for drilled and threaded holes using quadrinate referencing and lighting techniques to ensure pixel-perfect accuracy.

Challenges in Inspecting Drilled and Threaded Holes

- Large Size of Parts:

- Large components, such as engine blocks, turbine casings, or drilling rigs, pose challenges in capturing the entire surface area for detailed inspection.

- Complex Geometries:

- Drilled and threaded holes often have complex shapes, varying diameters, and depths that require detailed analysis.

- Precision Requirements:

- Deviation in hole positioning, diameter, or threading quality can lead to misalignment during assembly or failure under operational stress.

- Surface Reflectivity:

- Metal surfaces often reflect light, creating noise in the captured images and affecting the accuracy of inspections.

- High Volume Production:

- Inspecting each part manually in a high-volume production line is time-intensive and error-prone.

How Machine Vision Solves These Challenges

Machine vision systems leverage high-resolution cameras, lighting setups, and AI-driven algorithms to automate the inspection process. For large parts with drilled or threaded holes, these systems ensure precise measurements and defect detection by using advanced techniques like quadrinate referencing and pixel-matching.

1. Quadrinate Referencing for Accurate Positioning

Quadrinate referencing divides the large part into coordinate grids (x, y, z axes) to ensure that each section, including drilled or threaded holes, is inspected with precision. Here’s how it works:

- Grid Division: The surface of the part is divided into smaller quadrants, creating a coordinate map. Each quadrant is assigned specific reference points.

- Camera Alignment: Multiple cameras are strategically positioned to focus on different quadrants, ensuring complete surface coverage without the need for repositioning the part.

- Coordinate Matching: The system uses predefined CAD models or design blueprints to align the inspected part with its digital counterpart. This ensures that the position, diameter, and threading of each hole are verified against design specifications.

- Micron-Level Tolerance: The system calculates deviations at the micron level, highlighting even the slightest misalignment or defect in drilled or threaded holes.

2. Lighting Techniques for Enhanced Image Clarity

Proper lighting is critical for capturing high-quality images, especially for reflective metal surfaces and complex geometries of drilled or threaded holes.

- Coaxial Lighting: Ideal for reflective surfaces, coaxial lighting directs light at an angle, minimizing glare and enhancing the visibility of the hole's edges.

- Structured Lighting: Projects a patterned light (e.g., grids or lines) onto the surface. Variations in the pattern reveal dimensional defects or irregularities in hole threading.

- Ring Lighting: Provides uniform illumination around the hole, making it easier to inspect threading quality and hole depth.

- Backlighting: Used to create a silhouette of the drilled hole, ensuring accurate measurement of its diameter and position.

3. Depth Measurement with 3D Vision

- Stereo Cameras: Use two cameras to capture images from different angles, creating a 3D view of the hole.

- Laser Triangulation: A laser beam is projected onto the surface, and a sensor captures the reflected light to measure depth.

- Time-of-Flight (ToF) Sensors: Measure the time taken for light to travel to the hole and back, calculating the depth.

Applications: Measuring the depth of threaded or drilled holes to verify they meet specifications.

Benefits:

- Provides detailed information about the depth and shape of the hole.

- Effective for identifying shallow drilling or incomplete threading.

4. Edge Detection and Contour Analysis

Edge detection and contour analysis are crucial for evaluating the dimensions, shapes, and threading quality of holes. These techniques use advanced image processing algorithms to identify and measure key features of the hole.

Techniques for Edge Detection:

- Gradient-Based Methods: Identifies edges by analyzing changes in pixel intensity.

- Canny Edge Detection: A popular method for detecting sharp edges, ideal for analyzing circular and threaded features.

- Hough Transform: Used to detect circular shapes and measure diameters with high accuracy.

Contour Analysis:

- Shape Matching: Compares the detected contour of the hole against reference shapes to identify deviations.

- Thread Analysis: Analyzes the contours of threads for uniformity and completeness.

- Burr Detection: Identifies irregularities around hole edges, such as burrs or rough finishes.

Advantages of Using Machine Vision for Drilled and Threaded Holes

- Enhanced Precision: Machine vision systems achieve micron-level accuracy, ensuring that drilled and threaded holes meet strict tolerance requirements.

- Improved Efficiency: Automated inspection reduces inspection time, enabling high-speed production lines to maintain quality without delays.

- Consistent Quality: Eliminates human error, ensuring consistent inspection results across all parts.

- Data-Driven Insights: Real-time data and analytics help manufacturers identify defect patterns and optimize production processes.

- Cost Savings: Reduces material waste and rework costs by identifying defects early in the production process.

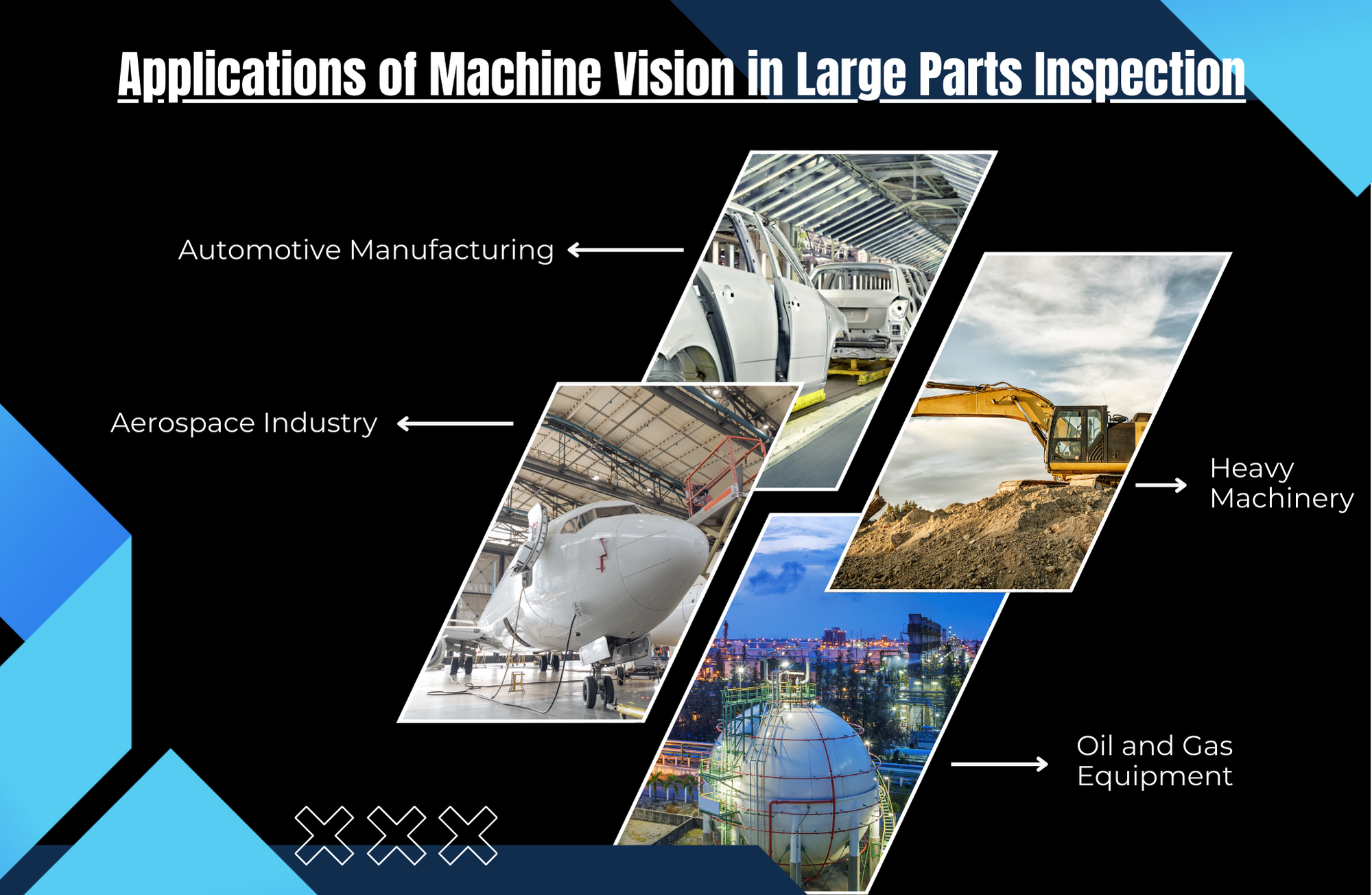

Applications of Machine Vision in Large Parts Inspection

- Aerospace Industry: Inspection of turbine casings, wings, and fuselage components for drilled or threaded holes ensures structural integrity and safety.

- Automotive Manufacturing: Ensures accurate drilling and threading in engine blocks, gearboxes, and chassis components for seamless assembly.

- Oil and Gas Equipment: Verifies the integrity of threaded holes in large drilling equipment and pipeline components.

- Heavy Machinery: Inspects critical parts such as hydraulic cylinders and crane components to prevent failures in heavy-duty applications.

Implementation of Machine Vision for Large Parts Inspection

- System Design: Assess the dimensions, material, and inspection requirements of the large parts to design a tailored machine vision solution.

- Camera and Lighting Setup: Select high-resolution cameras and appropriate lighting techniques to optimize image quality.

- AI Training: Train machine learning models using sample images of defects and acceptable parts to improve detection accuracy.

- Integration with Production Line: Seamlessly integrate the machine vision system with existing production equipment to enable real-time inspection.

- Testing and Calibration: Conduct thorough testing and calibration to ensure reliable performance under operational conditions.

Large parts inspection for drilled and threaded holes is a critical process that demands precision and efficiency. Machine vision technology, with its advanced imaging and AI capabilities, provides a reliable solution for inspecting large components. By leveraging quadrinate referencing, sophisticated lighting techniques, and pixel-perfect accuracy, Intelgic’s machine vision solutions ensure consistent quality, reduce operational costs, and enhance productivity across industries. For manufacturers aiming to achieve excellence in quality control, adopting machine vision is not just an option—it’s a necessity.