Surface Inspection Using AI-Powered AOI Systems

Published on: Oct 29, 2024

Written by: Soumen das

Surface Inspection Using AI-Powered AOI Systems

Automated Optical Inspection (AOI) has transformed the field of quality control by enabling precise, consistent, and efficient inspection of product surfaces. When combined with artificial intelligence (AI), AOI systems become even more powerful, capable of identifying defects and inconsistencies that may be invisible to traditional methods. AI-powered AOI systems are now integral to industries ranging from electronics and automotive to textiles and food processing, ensuring product quality while reducing the costs associated with manual inspections.

This guide provides an in-depth look at how AI-powered AOI systems work, their benefits, and their applications across various industries.

What is an AI-Powered AOI System?

An AI-powered AOI system uses a combination of cameras, sensors, lighting, and AI algorithms to inspect product surfaces automatically. Unlike traditional AOI, which relies on static image processing, AI-powered AOI incorporates machine learning and computer vision techniques, allowing it to learn from previous inspection data, recognize complex defect patterns, and adapt to variations in product surfaces.

By leveraging AI, AOI systems can detect a wide range of surface defects, such as scratches, discolorations, cracks, contamination, and structural deformations, with greater accuracy and at higher speeds than conventional methods.

Key Components of AI-Powered AOI Systems

An AI-powered AOI system comprises several components, each serving a specific role in the inspection process:

- High-Resolution Cameras: These cameras capture detailed images of the product surface, allowing for microscopic-level inspection. Multiple cameras may be used to cover all angles and surfaces.

- Lighting Systems: Effective lighting is essential for capturing clear, high-contrast images. Structured, coaxial, and ring lighting are commonly used to highlight surface features and defects.

- Sensors: Sensors help monitor environmental variables such as position, orientation, and speed of objects on the production line. In combination with cameras, they ensure that the AOI system captures images with precision.

- AI Algorithms: The AI layer processes images to detect defects. Algorithms are trained using large datasets to recognize defect patterns and differentiate between acceptable variations and actual defects.

- Controller: GPU based controller is essential for AI driven AOI systems. If multiple cameras are used in detecting defects, high processing power is needed in the controller.

How AI Enhances AOI for Surface Inspection

AI brings several key advantages to AOI, making it better suited for complex inspection tasks:

- Self-Learning Capabilities: AI algorithms can be trained with thousands of defect and non-defect images, improving their ability to detect subtle defects and patterns that might otherwise be missed by traditional AOI systems.

- Adaptability to Variations: Unlike static AOI systems that require rigid programming for each defect type, AI-powered AOI can adapt to product variations and learn to recognize new defect patterns without manual reprogramming.

- Improved Accuracy and Consistency: AI systems reduce human error and provide consistent, reliable results, minimizing the risk of false positives and false negatives, especially in high-precision industries like electronics and semiconductor manufacturing.

- Real-Time Feedback: AI-powered AOI systems can operate in real time, identifying defects and providing feedback instantly, allowing production teams to address issues as they arise rather than after a batch has been completed.

Types of Defects Detected by AI-Powered AOI Systems

AI-powered AOI systems are versatile and can detect various types of defects on different types of surfaces:

- Surface Scratches and Abrasions: Common in metals and glass, these are identified by changes in texture or reflection.

- Discoloration: Seen in fabrics, food items, and electronics, discoloration indicates contamination or material inconsistency.

- Cracks and Fractures: Detected in ceramics, glass, and semiconductor wafers, cracks can impact structural integrity.

- Blemishes or Foreign Particles: Detected in food, packaging, and cosmetic items, where foreign particles affect product safety.

- Dimensional Variations: Essential in industries like automotive and aerospace, where precise measurements are required for assembly and performance.

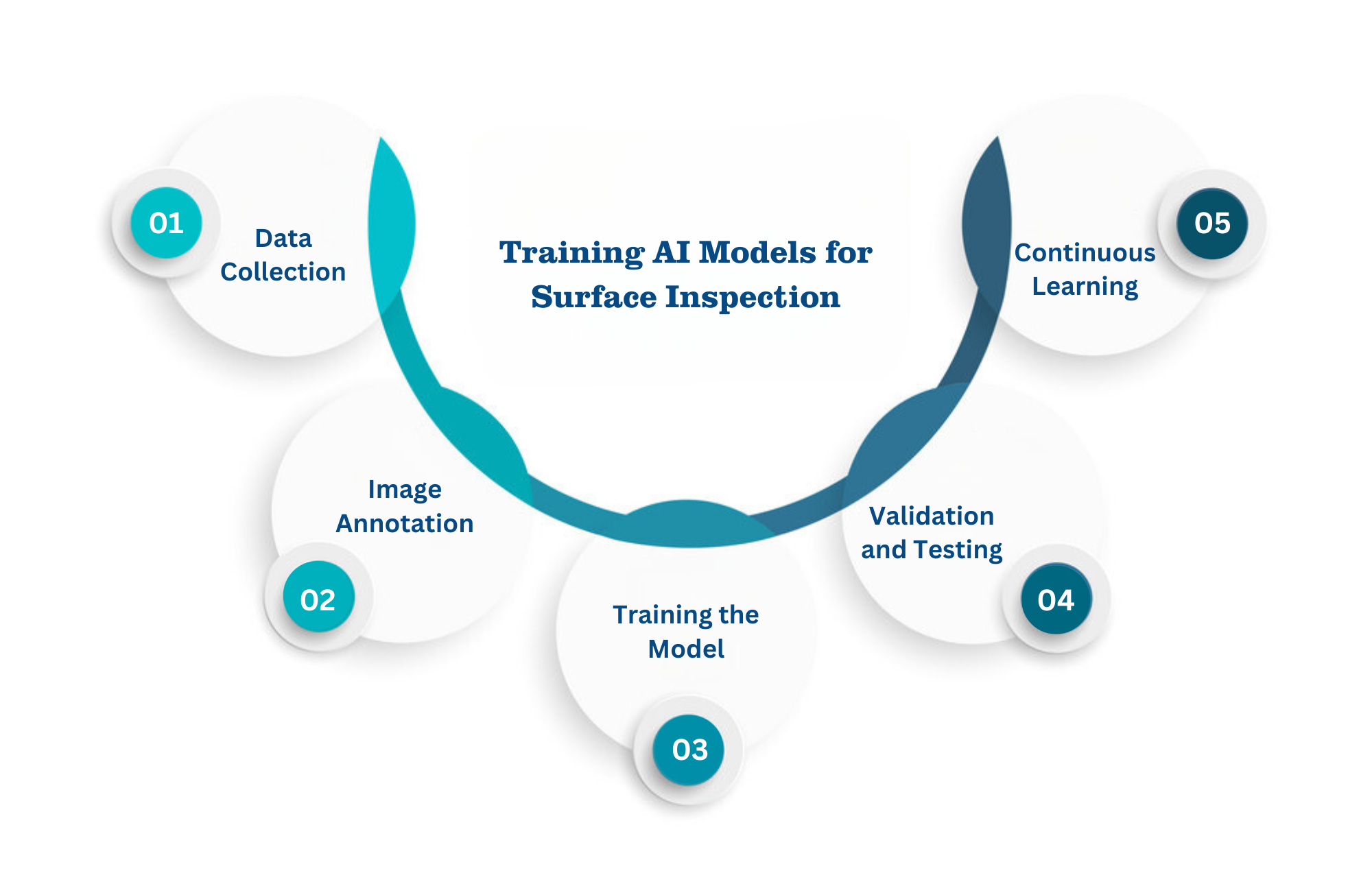

Training AI Models for Surface Inspection

One of the most critical steps in deploying an AI-powered AOI system is training the AI model to recognize defects. This involves several key steps:

- Data Collection: Large datasets of defect and non-defect images are collected, covering various product surfaces and possible defect types.

- Image Annotation: Defects are manually labeled in images to help the AI model learn the difference between acceptable variations and true defects.

- Training the Model: The model is trained using deep learning algorithms, such as convolutional neural networks (CNNs), which are highly effective in image recognition tasks.

- Validation and Testing: After training, the model undergoes rigorous testing and validation to ensure it accurately detects defects in real-world conditions.

- Continuous Learning: The AI model continues to improve with additional data, adapting to new types of defects and product variations encountered during production.

Applications of AI-Powered AOI in Surface Inspection

AI-powered AOI systems are highly adaptable and can be customized to meet the needs of various industries:

- Electronics Manufacturing: Identifies microscopic defects in printed circuit boards (PCBs), connectors, and chips, where even minor defects can lead to performance issues.

- Automotive Industry: Used for inspecting paint finishes, sheet metal surfaces, and engine components to ensure structural integrity and aesthetic quality.

- Textile and Apparel: Detects defects in fabric such as holes, tears, and stains, ensuring high-quality output and reducing waste in textile production.

- Food and Beverage: Ensures product quality by identifying surface contaminants, color irregularities, and structural defects in packaged goods, fruits, and vegetables.

- Pharmaceuticals: Examines packaging for cracks, leaks, or foreign particles to maintain safety standards.

- Metal and Glass Processing: Inspects metal sheets, pipes, glass panels, and lenses for scratches, dents, or other imperfections that can affect performance and safety.

Advantages of Using AI-Powered AOI Systems

Adopting AI-powered AOI systems offers numerous benefits, including:

- Higher Inspection Speed: Real-time defect detection accelerates the inspection process, enabling faster production cycles without compromising quality.

- Improved Accuracy and Repeatability: AI reduces human error and provides consistent results, enhancing the overall quality of the product.

- Reduced Labor Costs: Automated inspection eliminates the need for manual inspection, reducing labor costs and allowing employees to focus on higher-value tasks.

- Scalability: AI-powered AOI systems are scalable and can be adapted to inspect new products, surfaces, or defect types with minimal reprogramming.

- Data Insights for Quality Improvement: The data gathered from AI-powered inspections can be analyzed to identify patterns and root causes of defects, enabling continuous improvement in manufacturing processes.

Challenges and Considerations in Implementing AI-Powered AOI Systems

Despite the benefits, implementing an AI-powered AOI system comes with certain challenges:

- Data Collection and Labeling: Large volumes of defect images are required to train the AI model, and the process of labeling defects can be time-consuming.

- Initial Costs: AI-powered AOI systems involve upfront costs for equipment, software, and model training, although these costs are typically offset by long-term savings.

- Integration with Existing Systems: Integrating AI-powered AOI with existing production lines can be complex, requiring compatibility with other hardware and software.

- Maintenance and Updates: Continuous learning and adaptation mean that AI models need regular updates and occasional retraining to maintain accuracy.

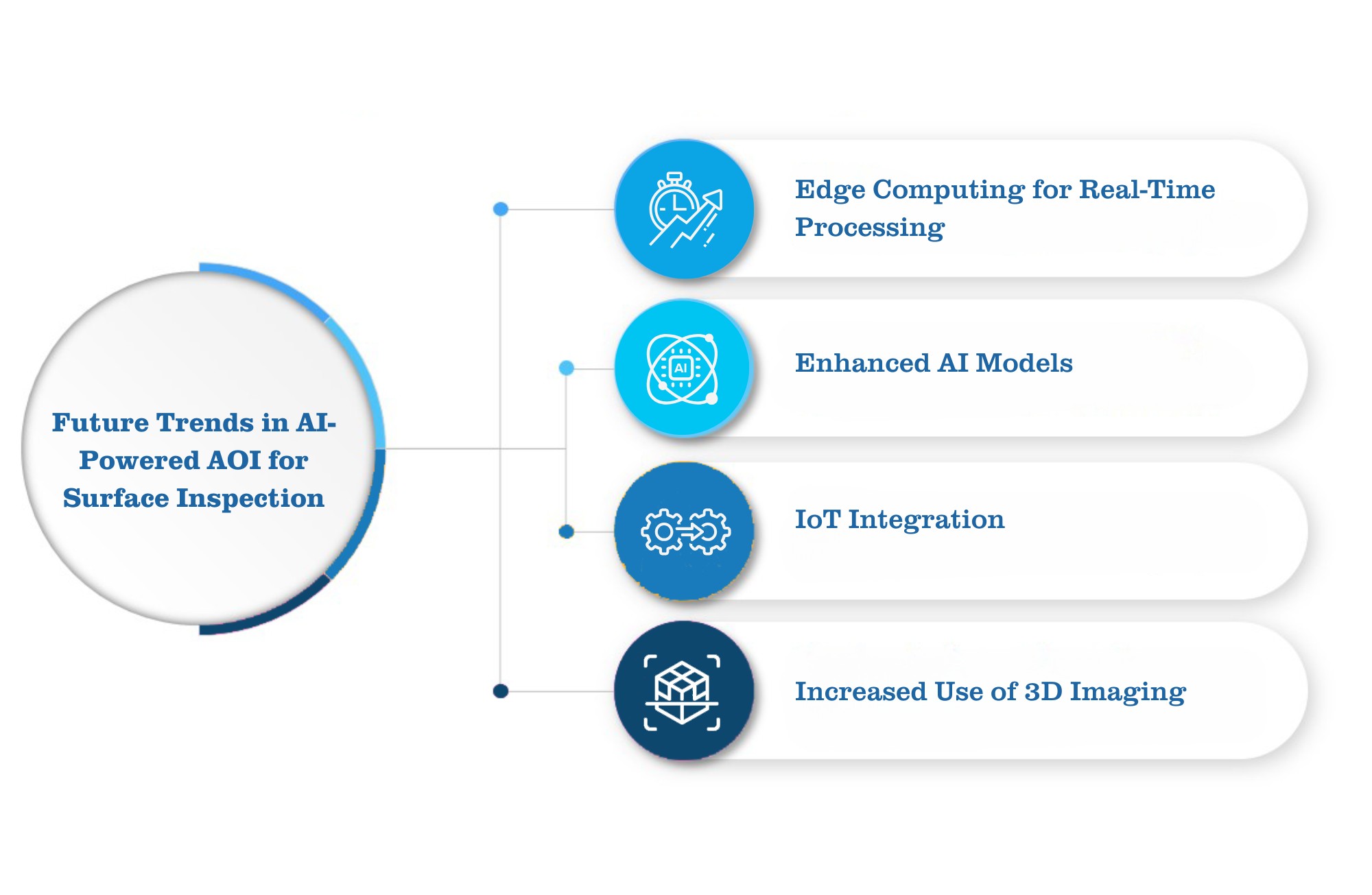

Future Trends in AI-Powered AOI for Surface Inspection

As technology advances, the capabilities of AI-powered AOI systems are expected to expand:

- Edge Computing for Real-Time Processing: Moving AI processing to the edge allows AOI systems to analyze data on-site, reducing latency and enabling faster response times.

- Enhanced AI Models: Future AOI systems may leverage advanced AI models such as transformer networks for improved defect recognition, particularly in complex or irregular surfaces.

- IoT Integration: Combining AOI with the Internet of Things (IoT) enables seamless data exchange, allowing inspection data to feed into larger quality control and predictive maintenance systems.

- Increased Use of 3D Imaging: AI-powered 3D AOI systems offer more detailed surface analysis, useful for applications requiring depth information, such as inspecting structural defects in automotive or aerospace parts.

Transforming Quality Control with AI-Powered AOI

AI-powered AOI systems represent a significant advancement in surface inspection technology, providing manufacturers with a powerful tool to ensure product quality, reduce defects, and improve efficiency. By leveraging AI’s adaptability and precision, these systems detect complex surface defects across a wide range of industries, from electronics and automotive to textiles and food processing.

As AI technology continues to evolve, AI-powered AOI systems will become even more accurate, versatile, and efficient, setting new standards for quality control in modern manufacturing.