Defect Detection Systems for Manufacturing

Published Jun 20, 2024

In the competitive world of manufacturing, maintaining high quality is paramount. Defects in products not only lead to financial losses but also damage a company's reputation. To address these challenges, defect detection systems have become integral to the manufacturing process, ensuring that products meet stringent quality standards before reaching consumers. Among these systems, visual defect detection has proven to be highly effective in identifying surface and structural flaws that could compromise product integrity.

Visual Defect Detection for Manufacturing

Visual defect detection involves using imaging technologies to inspect products for surface and structural defects. These defects can include scratches, dents, cracks, discoloration, and misalignments. Traditional methods relied heavily on manual inspection, where trained operators would visually examine each product. However, this approach is time-consuming, prone to human error, and not scalable for high-volume production.

Automating Manual Inspection with Machine Vision Systems

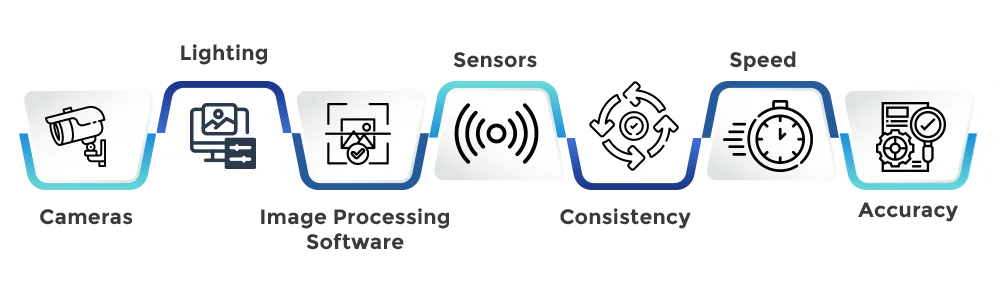

Machine vision systems have revolutionized defect detection by automating the manual inspection process. These systems use cameras, sensors, and image processing software to capture and analyze images of products. The key components of a machine vision system include:

- Cameras: Capture high-resolution images of products for detailed inspection.

- Lighting: Ensures that features of interest are well-illuminated, enhancing image clarity.

- Image Processing Software: Analyzes the captured images using algorithms to detect, measure, and classify defects.

- Sensors: Convert the captured light into electronic signals for processing.

By automating the inspection process, machine vision systems offer several advantages:

- Consistency: Provide uniform inspection standards, eliminating human variability and human error.

- Speed: Inspect products much faster than manual methods, increasing throughput.

- Accuracy: Detect smaller and more subtle defects that might be missed by human inspectors.

AI-Driven Defect Detection Systems

While traditional machine vision systems have significantly improved defect detection, the integration of artificial intelligence (AI) has taken these systems to the next level. AI-driven defect detection systems leverage machine learning algorithms to analyze vast amounts of image data, learning to identify defects with greater accuracy and adaptability.

Key Features of AI-Driven Systems:

- Deep Learning Algorithms: AI systems use deep learning models trained on large datasets of defect images. These models can recognize complex patterns and anomalies that traditional systems might miss.

- Self-Improvement: AI systems continuously learn and improve from new data, enhancing their accuracy and reliability over time.

- Adaptability: systems can adapt to new types of defects and variations in production, reducing the need for constant reprogramming.

Advantages of AI-Driven Defect Detection Systems

AI-driven defect detection systems offer numerous advantages over traditional methods:

- High Accuracy and Precision:

- AI systems can detect even the smallest defects with high accuracy, ensuring product quality and reducing false positives and negatives.

- Scalability:

- These systems can easily scale to accommodate growing production lines without significant additional costs or complexity.

- Real-Time Processing:

- AI-driven systems can process and analyze data in real-time, enabling immediate corrective actions and reducing downtime.

- Cost Efficiency:

- By reducing defects, rework, and waste, AI systems can lower overall production costs and improve profitability.

- Enhanced Predictive Maintenance:

- AI systems can predict when equipment needs maintenance, preventing unexpected breakdowns and prolonging the lifespan of machinery.

Intelgic's AI-Driven Defect Detection System: Next generation machine vision

Intelgic's AI-driven defect detection system represents a significant advancement in the field of quality control. Designed to meet the diverse needs of modern manufacturing, Intelgic's system offers unparalleled accuracy, efficiency, and adaptability.

Key Features of Intelgic’s System:

- Advanced AI Algorithms: Intelgic uses state-of-the-art deep learning models to identify defects with exceptional precision.

- Cloud-Based Processing: Leveraging cloud computing, Intelgic’s system processes large volumes of data quickly and efficiently.

- Scalability: Easily scale the system to match production demands, ensuring consistent quality across all product lines.

- User-Friendly Interface: Intelgic’s intuitive interface allows for easy integration and operation, minimizing the learning curve for operators.

- Continuous Improvement: The system continuously learns from new data, improving its performance and adapting to new defect types over time.

Benefits of Choosing Intelgic’s AI-Driven Defect Detection System:

- Unmatched Accuracy: Detects even the most subtle defects, ensuring the highest quality standards.

- Simplicity and Scalability: Intelgic’s machine vision just needs a camera setup that connects with the AI server. Unlike traditional machine vision systems, you do not need a bulky setup for each line. Use the same AI for multiple lines. Overall, it's a simple but powerful system with minimum setup and space requirements.

- Cost Savings: Minimizes rework and waste, lowering overall production costs.

- Increased Efficiency: Automates the inspection process, reducing manual labor and speeding up production.

- Enhanced Flexibility Adapts to various manufacturing environments and product types, providing a versatile solution for quality control.

Defect detection is a critical component of modern manufacturing, ensuring that products meet stringent quality standards. While traditional methods have served their purpose, the advent of machine vision and AI-driven systems has revolutionized the process, offering greater accuracy, efficiency, and adaptability. Intelgic’s AI-driven defect detection system stands at the forefront of this innovation, providing manufacturers with a powerful tool to enhance product quality and streamline operations. Embracing these advanced technologies is not only a competitive advantage but a necessity for staying ahead in today’s fast-paced industrial landscape.