Counting tablets, capsules, vials, treys, pallets and other small to large objects using vision AI in Pharmaceutical manufacturing.

Published March 07, 2024

Traditional methods of counting tablets, capsules, vials, and other products are labor-intensive and prone to human error. However, the advent of Vision AI technology is revolutionizing this crucial process, offering unprecedented precision and efficiency. Vision AI is transforming pharmaceutical product counting, marking a significant leap towards automation in the industry.

Understanding Vision AI in Pharmaceutical Counting

Typically, pharmaceutical items like capsules, tablets, and vials are quite small, rendering manual counting methods prone to inaccuracies. Additionally, certain machines employing traditional technologies for counting these diminutive products often yield imprecise outcomes.

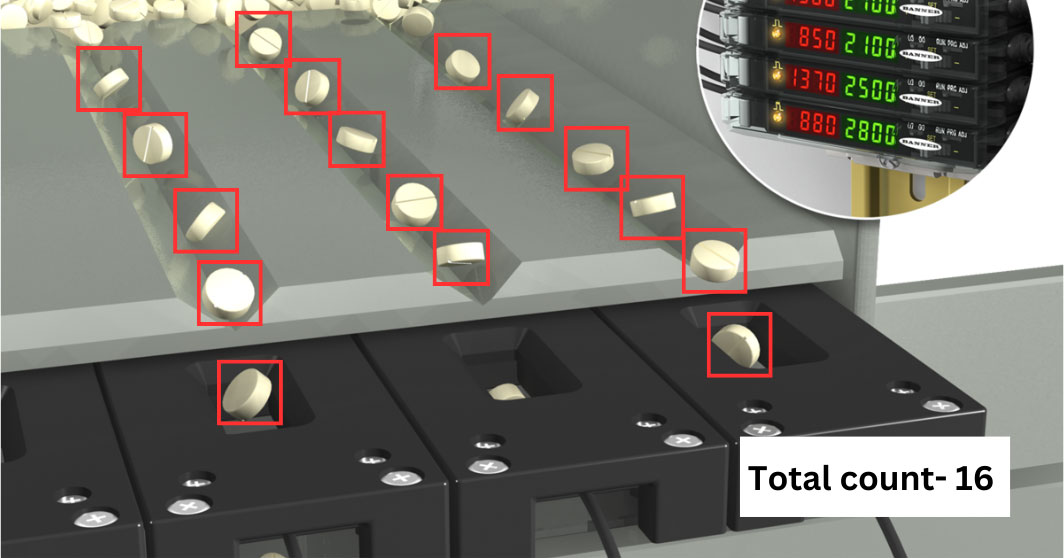

Vision AI addresses these challenges effectively. It utilizes cameras to capture live footage from production lines, assembly lines, or counting stations, and then forwards this live stream to a Vision AI algorithm. This AI processes the video streams and counts the products in real-time with unmatched accuracy, subsequently transmitting the counting information to existing ERP systems or other related platforms. The AI technology is applied to accurately count tablets, capsules, vials, and other products as they move through production lines. This automated process not only reduces human error but also significantly enhances production efficiency.

How Vision AI Works

Image/video Capture: High-resolution cameras positioned over conveyor belts or within counting machinery capture real-time images of pharmaceutical products as they pass through the production line.

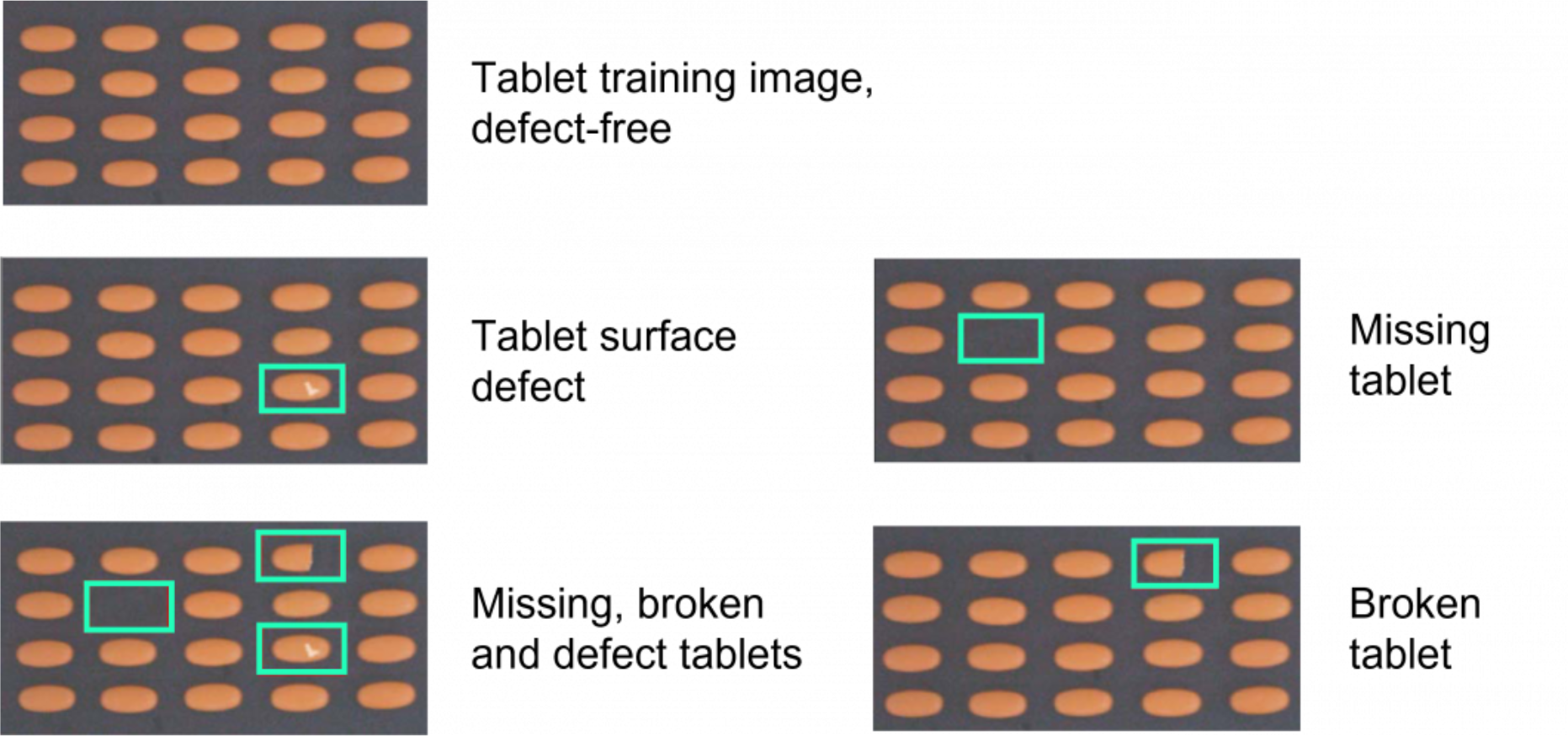

Image or video Analysis: Advanced AI algorithms analyze the captured images or live video streams to identify and count each product. These algorithms are trained to recognize different shapes, sizes, and types of pharmaceutical products, distinguishing them from one another and from any debris or irregularities.

Error Detection and vision inspection: Beyond counting, Vision AI systems can detect defects or anomalies in products, such as broken tablets or improperly filled vials. This dual capability ensures both accurate counting and quality control, flagging issues for human intervention when necessary.

Integration with Production Systems: The data generated by Vision AI systems can be integrated with other production systems, enabling real-time monitoring and adjustments to the manufacturing process. This integration facilitates a seamless flow of information and materials, optimizing overall production efficiency.

Vision AI platform: Vision AI algorithms and machine vision cameras work together to count products, tubs, pallets and other assets. The implementation of Vision AI becomes easier if you have an AI platform that supports all these features and you can connect your machine vision cameras to the AI algorithms easily and efficiently. Intelgic has a robust AI platform that is specifically designed for industrial use cases like product counting in pharmaceuticals. Talk to an expert to know how you can implement the Vision AI within your manufacturing and assembly lines.

Benefits of Implementing Vision AI

Accuracy and Precision: Vision AI significantly reduces counting errors, ensuring that the right quantity of products is packaged and distributed. This accuracy is crucial for maintaining regulatory compliance and customer trust.

Speed: AI-driven systems can process vast quantities of products at high speeds, far surpassing the capabilities of manual counting methods. This efficiency is key to meeting the high demand in the pharmaceutical industry.

Cost Savings: By automating the counting process, companies can reduce labor costs and minimize losses due to errors or defects. The initial investment in Vision AI technology is quickly offset by these savings.

Scalability: Vision AI systems can easily be scaled up or adapted to new products and processes, making them a flexible solution for companies of all sizes and across various stages of growth.

Data Collection and Analysis: These systems provide valuable data that can be analyzed to identify trends, forecast demand, and make informed decisions about production planning and inventory management.

Challenges and Considerations

While Vision AI offers numerous benefits, its implementation comes with challenges. High-quality image capture is essential, which can be influenced by lighting, speed of the production line, and the physical characteristics of the products. Additionally, developing and training accurate AI models requires expertise and resources. However, the ongoing advancements in AI technology and decreasing costs of implementation are making Vision AI more accessible and effective for pharmaceutical companie

Vision AI is setting a new standard for accuracy, efficiency, and quality control in the pharmaceutical industry. By automating the counting and inspection of tablets, capsules, vials, and other products, companies can achieve greater operational efficiency, reduce costs, and ensure the highest standards of product quality. As technology continues to advance, the adoption of Vision AI in pharmaceutical manufacturing and packaging is expected to grow, heralding a new era of innovation and automation in the industry.