AI powered Automated Optical Inspection (AOI) system

Published on: Oct 24, 2024

Written by: Soumen das

How AI is Revolutionizing Automated Optical Inspection (AOI): Making AOI Systems Smarter Than Ever

In today's fast-paced manufacturing environment, maintaining high-quality standards while increasing production speed is a critical challenge. Traditional quality inspection methods, such as manual inspection and rule-based Automated Optical Inspection (AOI) systems, have limitations in terms of speed, accuracy, and adaptability. The integration of Artificial Intelligence (AI) into AOI systems is changing the game, making these systems smarter, faster, and more capable than ever before.

AI-powered AOI systems not only enhance defect detection but also introduce learning capabilities that enable these systems to improve over time. From real-time data processing to adaptive learning and decision-making, AI is revolutionizing AOI in ways that were previously unimaginable. This article explores how AI is being used in AOI systems, the key benefits it brings, and its transformative impact on industries that rely on precision and quality.

What is Automated Optical Inspection (AOI)?

Automated Optical Inspection (AOI) is a technology used primarily in the manufacturing sector, where cameras and imaging systems capture high-resolution images of products (such as printed circuit boards, automotive parts, or consumer goods) to detect defects, inconsistencies, or anomalies. Traditionally, AOI systems relied on predefined rules, image templates, and algorithms that compare products to a "golden sample" (a perfect reference product). While effective to a point, rule-based AOI systems struggle with complex or variable defects, especially in environments where production lines handle diverse products or product designs change frequently.

.png)

The Role of AI in AOI Systems

The integration of Artificial Intelligence into AOI systems brings a level of intelligence, flexibility, and learning capability that traditional systems lack. Below, we explore how AI is transforming AOI systems to make them more effective and efficient.

1. Deep Learning for Defect Detection

One of the most significant advancements in AI-powered AOI systems is the use of deep learning, a subset of machine learning that excels at processing and interpreting image data. Deep learning models, particularly Convolutional Neural Networks (CNNs), are designed to recognize complex patterns, textures, and features within images.

- How it works: Instead of relying on fixed rules or templates, AI models are trained on vast datasets of labeled images. These datasets include examples of both defective and non-defective products. As the model processes these images, it learns to identify subtle patterns and anomalies that represent defects.

- Benefits: Deep learning enables AOI systems to detect defects that would be difficult for rule-based systems to identify, such as surface imperfections, subtle variations in texture, or hidden flaws. The system can detect defects even when they vary in size, shape, or appearance, making it highly adaptable to dynamic production environments.

2. Adaptive Learning and Continuous Improvement

AI-powered AOI systems have the unique ability to learn and improve over time. Unlike traditional AOI systems that require manual updates or reprogramming to adapt to new products or defect types, AI systems can continuously learn from new data.

- How it works: Once deployed, AI-powered AOI systems can be fine-tuned by feeding them additional images of new products or new types of defects. As the system processes more data, it becomes better at detecting defects, even in novel scenarios. This reduces the need for frequent manual intervention and improves the system's performance over time.

- Benefits: This continuous learning capability allows manufacturers to deploy AI-based AOI systems across diverse product lines without the need for extensive reconfiguration. The system adapts to evolving production requirements, reducing downtime and increasing overall inspection efficiency.

3. Handling Complex and Variable Defects

Traditional AOI systems often struggle with complex defects or defects that exhibit high variability. For example, subtle cracks, inconsistent solder joints, or surface deformations in metal parts may not conform to predefined rules, making them difficult to detect with rule-based systems. AI overcomes these challenges.

- How it works: AI models can be trained to recognize a wide range of defect types, including those that exhibit variability in their appearance. This allows AI-powered AOI systems to detect defects that may be inconsistent in size, shape, or location across different products. Deep learning algorithms excel at identifying these complex patterns without requiring manual reconfiguration.

- Benefits: Manufacturers benefit from more accurate defect detection, especially for high-precision industries such as semiconductors, automotive, and aerospace, where undetected defects could lead to catastrophic product failures.

4. Reduction of False Positives and False Negatives

Traditional AOI systems are prone to generating false positives (flagging non-defective products as defective) or false negatives (failing to detect actual defects). These errors can lead to unnecessary rework, increased costs, or defective products making it to market. AI reduces these errors significantly.

- How it works: AI-powered AOI systems can be trained to minimize false positives and false negatives by refining their decision-making algorithms. With more training data and better feature recognition, AI models become more accurate at distinguishing between genuine defects and acceptable variations in the product.

- Benefits: By reducing false positives, manufacturers can avoid unnecessary product rejections and rework, thereby improving production efficiency. Minimizing false negatives ensures that all defects are identified, enhancing product quality and reducing the risk of customer dissatisfaction or recalls.

5. Real-Time Data Processing and Decision Making

AI-based AOI systems can process and analyze data in real-time, enabling immediate feedback and decision-making. This is especially important in high-speed manufacturing environments where delays in defect detection can lead to significant waste or production downtime.

- How it works: By processing images and detecting defects in real-time, AI systems provide immediate feedback to operators. The system can flag defective products, trigger alerts, or automatically remove defective items from the production line without disrupting production flow.

- Benefits: Real-time inspection allows manufacturers to detect and address defects as soon as they occur, reducing scrap rates and preventing defective products from reaching the next stage of production. This leads to faster cycle times and improved overall efficiency.

6. Customizability and Flexibility for Different Industries

One of the key advantages of AI-powered AOI systems is their ability to be customized and adapted for different industries and specific product lines. Traditional AOI systems often require significant reconfiguration when moving from one product to another, but AI systems offer greater flexibility.

- How it works: AI models can be trained on product-specific datasets, allowing the system to adapt to the unique characteristics of each product. For example, an AOI system inspecting PCBs can be customized to detect issues like soldering defects or component misalignment, while a system inspecting automotive parts can be optimized for detecting cracks, surface wear, or dimensional inaccuracies.

- Benefits: This flexibility allows manufacturers across industries—whether in electronics, automotive, metal fabrication, pharmaceuticals, or textiles—to benefit from AI-powered AOI systems tailored to their specific quality control needs.

Key Benefits of AI-Powered AOI Systems

AI is transforming AOI by addressing the limitations of traditional systems and unlocking new capabilities. Here are the major benefits of integrating AI into AOI systems:

- Higher Accuracy: AI-powered AOI systems deliver higher detection accuracy by recognizing complex and subtle defects that traditional systems might miss. This leads to fewer defective products and higher product quality.

- Improved Adaptability: AI enables AOI systems to adapt to changes in the production process, such as new product designs, defect types, or materials. The system can continuously learn and evolve, ensuring it stays relevant as production needs change.

- Faster Time-to-Market: With automated inspection processes, manufacturers can reduce the time required for manual inspections or system reconfigurations, speeding up time-to-market for new products.

- Cost Efficiency: AI-powered AOI systems reduce the costs associated with manual inspections, defect-related rework, and product recalls. By catching defects earlier and more accurately, manufacturers can minimize material waste and optimize resource utilization.

- Scalability: AI-based AOI systems can be easily scaled to handle large production volumes, making them ideal for both small manufacturers and large-scale production facilities.

- Real-Time Monitoring: AI systems provide real-time feedback, helping manufacturers detect and address issues on the production line immediately. This minimizes production downtime and helps ensure continuous, high-quality output.

AI-Powered AOI in Action: Use Cases Across Industries

- Electronics Industry: In the production of Printed Circuit Boards (PCBs), AI-powered AOI systems detect soldering defects, component misplacement, and surface contamination. These systems improve yield rates by identifying defects earlier in the production process.

- Automotive Industry: AI-based AOI systems are used to inspect automotive parts, such as engines, brake components, and body panels, for surface defects, dimensional inaccuracies, and assembly issues. This ensures that only high-quality components are used in vehicle assembly.

- Metal Fabrication: In metal manufacturing, AI-powered AOI systems detect surface scratches, cracks, and corrosion in metal sheets or parts, ensuring they meet stringent quality standards before moving to the next stage of production.

- Pharmaceuticals: AI-based AOI systems inspect pharmaceutical products, such as pills and vials, for defects in shape, color, and packaging. This ensures compliance with regulatory standards and improves product safety.

- Textiles and Packaging: AI systems in AOI inspect fabrics and packaging materials for defects like tears, holes, or printing errors, ensuring that the final products are of high quality and free from flaws.

The Future of AI in AOI is here

As AI technology continues to evolve, AI-powered AOI systems will become even smarter, more adaptable, and more efficient. Future advancements may include the integration of edge computing to further reduce latency and improve real-time processing capabilities. Edge computing allows AI-powered AOI systems to process data locally, directly on the production line, instead of relying on cloud-based solutions. This not only reduces the time needed for decision-making but also minimizes the need for constant internet connectivity, making the systems more resilient and scalable for diverse manufacturing environments.

Integration with IoT and Industry 4.0

The future of AI in AOI will also see tighter integration with IoT (Internet of Things) technologies and Industry 4.0 standards. With IoT, AOI systems can collect and share data with other machines and systems across the factory floor, enabling real-time monitoring, predictive maintenance, and comprehensive quality control. For example, AOI systems could communicate with production robots or machinery to adjust processes dynamically when defects are detected. This level of integration creates a fully automated, interconnected, and adaptive manufacturing ecosystem.

AI-Driven Predictive Maintenance

As AI-powered AOI systems gather more data from inspections, they can move beyond defect detection to support predictive maintenance. By analyzing trends and patterns in the defects detected, AI systems can predict when equipment or machinery may fail or require maintenance. This capability allows manufacturers to schedule maintenance proactively, reducing downtime and preventing costly breakdowns on the production line.

Augmented Reality (AR) and Virtual Reality (VR) in AOI

The future of AI in AOI could also involve the use of Augmented Reality (AR) and Virtual Reality (VR) technologies for enhanced inspection and decision-making. Operators wearing AR glasses could receive real-time visual overlays of detected defects, allowing for more efficient manual intervention when needed. VR could be used to simulate complex inspection processes in virtual environments, training AI models to recognize and classify defects in new, controlled scenarios before deployment on the production floor.

Advanced AI Algorithms and Multimodal Systems

Future AOI systems will likely incorporate multimodal AI, combining data from multiple sources such as visual, infrared, X-ray, and even sound data to provide a more comprehensive analysis of products. This multimodal approach can detect a wider range of defects, including those that aren’t visible to the naked eye or standard imaging techniques. As AI algorithms advance, they will also become better at handling edge cases—such as rare defect types or unusual product variations—further improving the robustness of AOI systems.

Deep Learning Models on the Edge

As deep learning models evolve, they will become more compact and efficient, making it possible to deploy them on edge devices with limited processing power. This will enable AOI systems to perform complex defect detection tasks even in environments where cloud computing isn’t feasible, such as remote or highly secure production facilities.

Intelgic’s Robust AI-Powered AOI System

Intelgic offers a cutting-edge AI-powered Automated Optical Inspection (AOI) system designed to deliver unmatched accuracy and efficiency for defect detection. Unlike traditional AI systems that require thousands of images for training, Intelgic’s powerful AI software system is optimized to learn from a smaller dataset, speeding up the deployment process without compromising on accuracy. The system is equipped to identify defects in real-time and precisely locate them on the product. When a defect is found, the system captures and saves the defective area’s image for future reference and quality analysis.

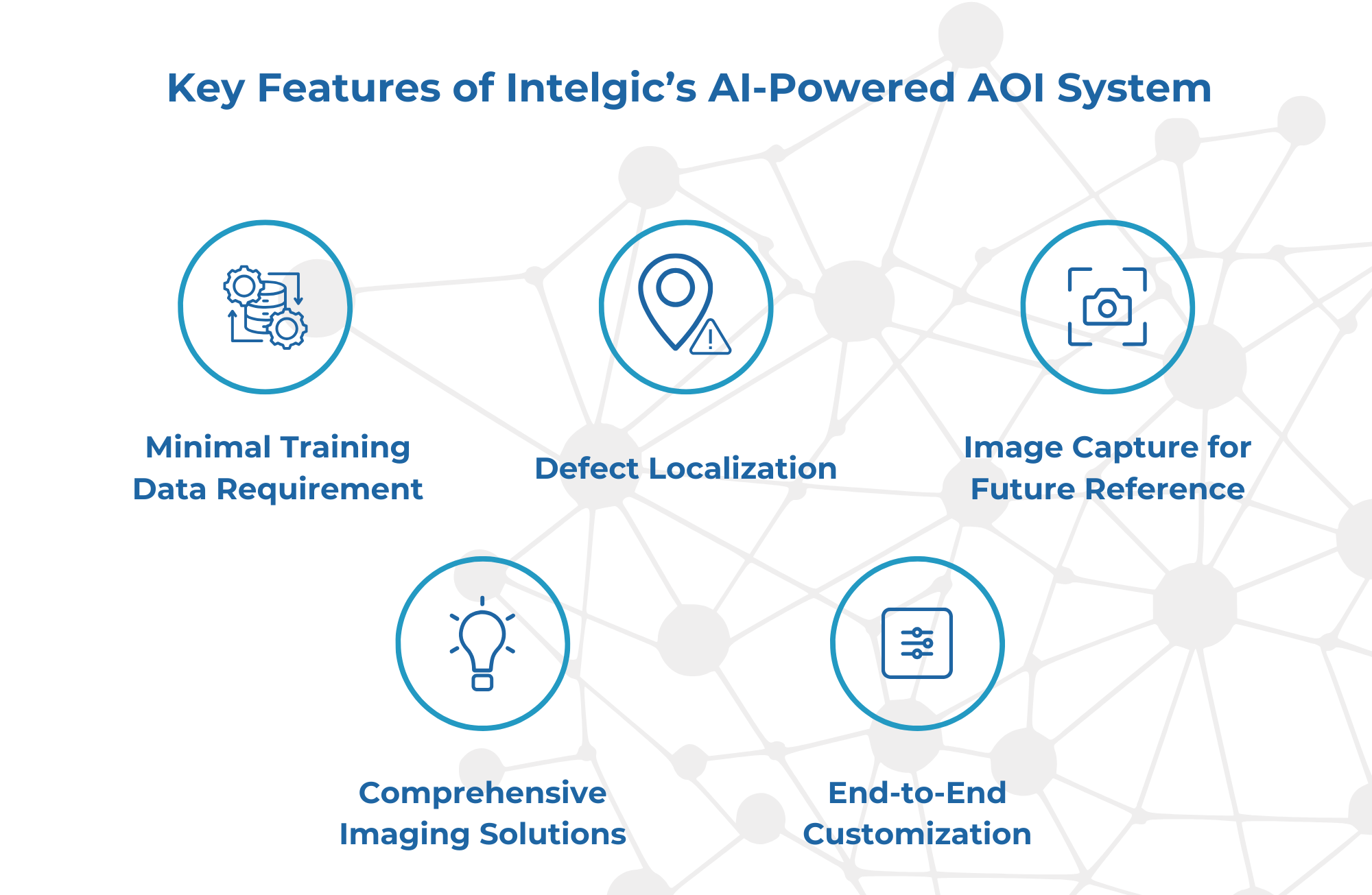

Key Features of Intelgic’s AI-Powered AOI System

- Minimal Training Data Requirement: Intelgic’s AI system does not require thousands of images for training, making it quicker to deploy.

- Defect Localization: The system accurately detects and pinpoints the location of defects, providing the exact coordinates of defects in large parts, sheets, pipes, or tubes.

- Image Capture for Future Reference: The system captures and stores images of detected defects for future analysis and quality control.

- Comprehensive Imaging Solutions: Includes machine vision cameras and controllers pre-installed with AI software for a complete, ready-to-use inspection solution.

- End-to-End Customization: Intelgic designs and builds customized AOI systems with mechanical, electrical, and optical solutions, tailored for complex and unique production lines.

Intelgic’s Customized AOI System for Complex Inspection Needs

Intelgic understands that every manufacturing environment has unique requirements, and a one-size-fits-all approach is often insufficient. That’s why Intelgic offers customized AOI systems designed specifically for complex inspection scenarios. These systems are built from the ground up, incorporating specialized mechanical, electrical, and optical solutions to meet the precise needs of the production line.

- Mechanical Customization: Intelgic engineers tailor the mechanical components of the AOI system, such as conveyors, lighting setups, and robotic integration, to ensure that the system aligns perfectly with the physical layout and workflow of the production line.

- Electrical Customization: The system’s electrical components, including controllers and communication interfaces, are customized to ensure seamless integration with existing production equipment, PLCs, and industrial control systems.

- Optical Customization: Intelgic provides advanced optical systems, such as high-resolution cameras, lighting, and lens configurations, to optimize the detection of even the most subtle defects. These solutions are particularly beneficial for industries where surface quality is critical, such as automotive, aerospace, and metal fabrication.

With Intelgic’s fully customizable AOI system, manufacturers can be assured of a tailored solution that fits their specific operational challenges, improving defect detection accuracy, production efficiency, and overall product quality.

AI is making Automated Optical Inspection (AOI) systems smarter, faster, and more efficient than ever before. By leveraging deep learning, adaptive learning, and real-time decision-making, AI-powered AOI systems can detect a wide range of complex and subtle defects that traditional methods struggle to identify. These systems are more flexible and scalable, able to handle diverse products and production environments with ease.

The future of AI in AOI looks promising, with advancements in edge computing, IoT integration, predictive maintenance, and multimodal inspection capabilities. As these technologies continue to evolve, AI-powered AOI systems will play a pivotal role in transforming manufacturing, enabling higher-quality products, reduced waste, and greater efficiency across industries.

For manufacturers seeking to maintain a competitive edge, adopting AI-powered AOI systems is not just a luxury but a necessity. As industries move towards fully automated, interconnected production environments, AI-driven defect detection will remain at the forefront of ensuring product quality, operational efficiency, and customer satisfaction.