Product counting in production and assembly lines using Vision AI

Published April 01, 2024

In the modern manufacturing and assembly landscape, precision, efficiency, and automation are paramount. Vision AI, or Artificial Intelligence that interprets and analyzes visual data, has become a pivotal technology in transforming these industries. One of its remarkable applications is in product counting on production and assembly lines, where it offers a blend of accuracy, speed, and reliability unattainable by traditional methods.

A shift from the traditional counting methods to Vision AI

Traditionally, product counting has been conducted manually or through basic mechanical systems that are inaccurate, expensive, hard to set up and cumbersome to procure. These methods are also labor-intensive, time-consuming, and prone to errors, especially in high-volume production environments. Moreover, they lack the flexibility and scalability needed to adapt to changing product types and production rates.

Vision AI introduces a game-changing approach by utilizing advanced image processing and machine learning algorithms. It analyzes visual data from cameras installed along production and assembly lines to count products in real time. This technology can handle diverse product types, from tiny electronic components to large automotive parts, with exceptional accuracy and speed

How Vision AI Works in Product Counting

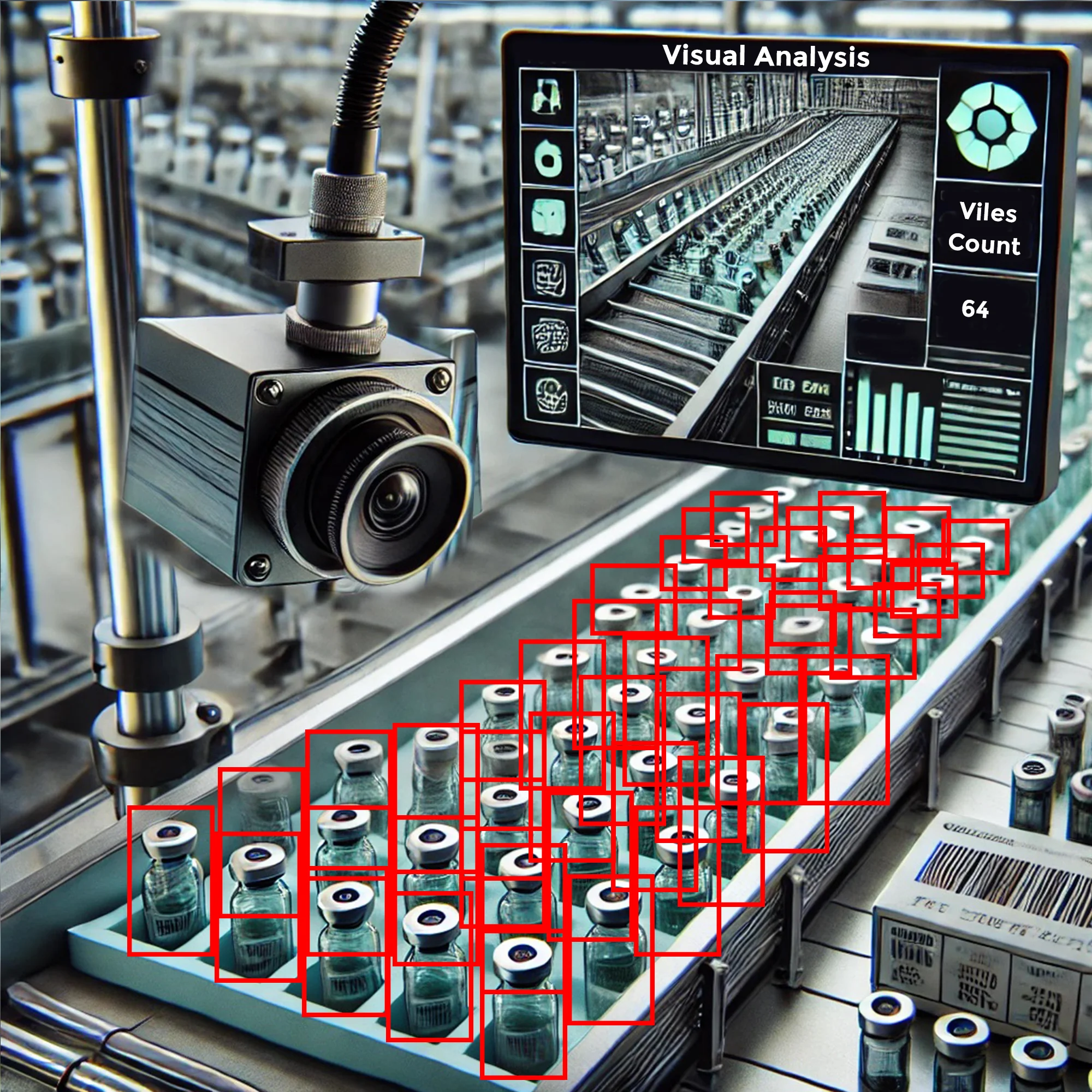

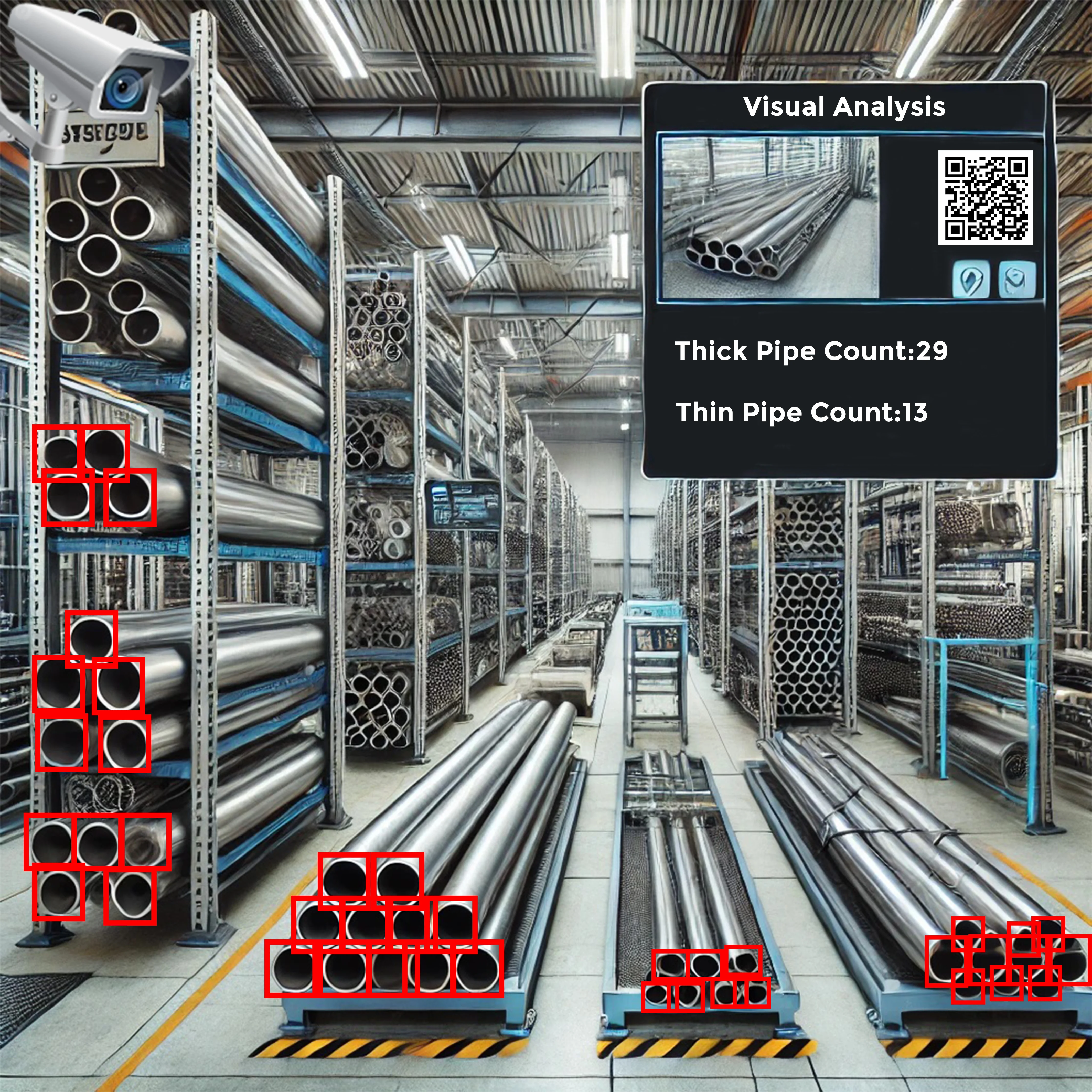

Vision AI systems comprise high-resolution cameras, computer vision algorithms, and machine learning models. These components work in tandem to capture and analyze images of products on the conveyor belts or assembly lines.

Image Capture: High-resolution cameras strategically placed along the lines capture continuous visual data of moving products.

Image Processing: Computer vision algorithms preprocess the images, adjusting lighting, contrast, and orientation to enhance feature detection.

Object Detection and Counting: Machine learning models trained on product images identify and count each item, regardless of its orientation, size, or speed on the line.

Data Integration and Reporting: The system integrates with the production management software, updating inventory levels in real time and generating detailed reports on production metrics.

Benefits of Vision AI in Product Counting

Enhanced Accuracy and Consistency

Vision AI minimizes human error and ensures consistent counting across all production shifts and lines. Its precision is crucial for inventory management, order fulfillment, and quality control.

Increased Efficiency and Productivity

Automating the counting process with Vision AI accelerates production cycles and frees up employees for higher-value tasks, boosting overall productivity.

Scalability and Flexibility

Vision AI systems can easily adapt to new product types or changes in production volume, making them ideal for dynamic manufacturing environments.

Real-Time Data and Analytics

Immediate access to accurate production data enables proactive decision-making, optimizing inventory management and reducing waste.

Case Study: Intelgic's Vision AEye Platform

Inteligic's Vision AEye platform exemplifies the integration of Vision AI in product counting. It processes video streams from surveillance cameras to detect and count products in real time. With its advanced object detection algorithms, Vision AEye can identify a wide range of items, triggering alerts and generating reports on detected incidents or object counts.

The platform's real-time processing capability ensures that inventory levels are continuously updated, providing valuable insights for production planning and inventory control. Vision AEye's application in product counting not only enhances operational efficiency but also supports strategic business decisions through data-driven insights.

Vision AI is revolutionizing product counting in production and assembly lines, offering unparalleled accuracy, efficiency, and adaptability. As industries continue to evolve towards smarter manufacturing processes, the integration of advanced technologies like Vision AI will become increasingly essential. Intelgic's Vision AEye platform showcases the potential of Vision AI to transform production operations, marking a significant step forward in the journey towards fully automated and intelligent manufacturing systems.