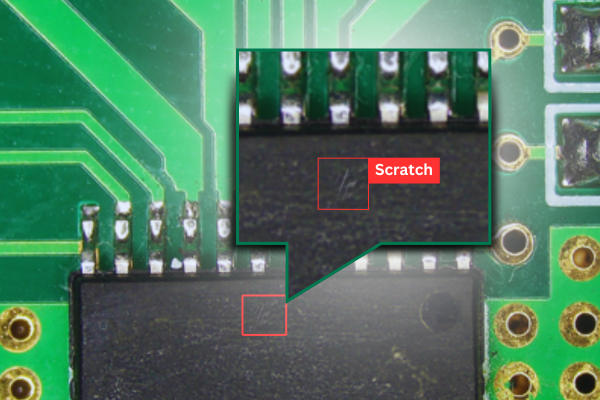

Detecting microscopic defects has always been a significant challenge in manufacturing due to their nature—they are invisible to the naked eye. This issue is particularly pronounced in sectors like electronics, where tiny defects can lead to critical failures, and in the production of plastic products, especially those that are translucent or white. Flooring and coating materials manufacturers also struggle with identifying minute imperfections that can affect product quality and durability.

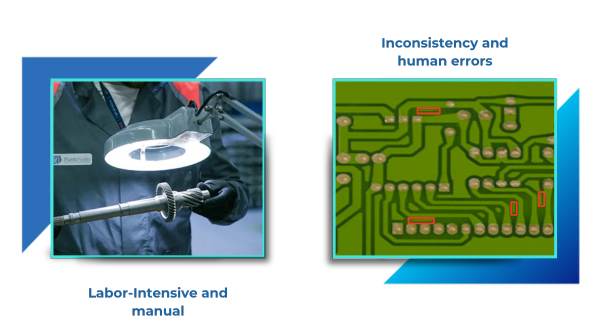

Labor-Intensive and manual: Manufacturers traditionally rely on human inspectors to identify defects using microscopes. Each product is placed under the microscope one by one, and the lens is adjusted to zoom in on the image, requiring substantial time and effort.

Inconsistency and human errors: Human inspection is prone to variability and fatigue, leading to inconsistent results and missed defects.

Expensive and Inflexible: Traditional machine vision systems are expensive. Some companies use these costly machine vision systems for their quality control. However, you need one system for each line, leading to high costs and moreover they are closed systems - once they are programmed, they are difficult to change.

Accuracy Issues: Traditional image processing techniques may not always detect subtle defects, resulting in quality control issues.

They are bulky and hard to set up: Traditional Traditional systems occupy a lot of space in the production room and they are not easy to set up.

Intelgic offers a groundbreaking approach to microscopic defect detection, leveraging machine vision cameras and advanced AI algorithms to deliver superior results. Here’s how Intelgic transforms the defect detection process:

Generative AI for Pixel Enhancement: Intelgic’s machine vision system uses AI to generate additional pixels within the image, enhancing resolution and making even the smallest defects visible. Any decent high-resolution camera can be used to capture images suitable for this process.

Flexible and Scalable: Unlike traditional systems, Intelgic’s solution is highly scalable and flexible and can be easily reconfigured for different production lines with just additional cameras.

Real-Time Analysis: AI models analyze images in real-time, providing instant feedback and defect detection.

Adaptive Learning: Intelgic’s AI algorithms continuously improve by learning from new data, ensuring ongoing accuracy and reliability.

Advanced Algorithms: Intelgic uses cutting-edge image processing techniques to highlight and identify defects more effectively.

Customizable: system can be tailored to specific product requirements, ensuring optimal performance across various manufacturing processes.

By utilizing machine vision cameras and AI, Intelgic reduces the need for multiple expensive systems, cutting down overall costs by 2x to 10X

Enhanced image quality and advanced algorithms ensure superior defect detection accuracy

The system is easy to set up and reconfigure, making it ideal for dynamic production environmen

Intelgic’s system can be scaled across different production lines without significant additional investmen

Detecting microscopic defects is crucial for maintaining high-quality standards in manufacturing. Traditional methods, whether manual inspection or conventional machine vision systems, have significant limitations in terms of cost, flexibility, and accuracy. Intelgic’s AI-powered vision systems represent a significant leap forward, offering a flexible, accurate, and cost-effective solution. By combining high-resolution machine vision cameras with state-of-the-art AI algorithms, Intelgic ensures that manufacturers can detect even the smallest defects, enhancing product quality and reliability.

Explore how Intelgic can revolutionize your defect detection processes and ensure the highest quality for your products

©2025 Intelgic Inc. All Rights Reserved.