How Machine Vision AI Enhances Conveyor Belt Inspection Automation in Manufacturing

Published on: May 07, 2025

Written by: Content team, Intelgic

How Machine Vision AI Enhances Conveyor Belt Inspection Automation in Manufacturing

In the realm of modern manufacturing, where operational efficiency and product quality are paramount, the role of conveyor systems is both foundational and strategic. Conveyor belts serve as the arteries of production lines, facilitating the seamless movement of raw materials, semi-finished goods, and completed products. However, undetected wear, damage, or malfunction in these systems can cause costly disruptions, compromise product integrity, and pose significant safety risks.

To overcome these challenges, manufacturers are increasingly deploying advanced Machine Vision AI systems for conveyor belt inspection, enabling real-time detection of anomalies and the automatic generation of intelligent alerts to facilitate immediate and informed corrective actions.

Why it’s Important to monitor Conveyor Belts

Conveyor belts are ubiquitous across industries—from automotive and electronics to pharmaceuticals, packaging, and food processing. Their continuous operation is critical to maintaining high throughput and minimizing production delays.

Effective monitoring of conveyor belts provides several key advantages:

- Early detection of mechanical wear or surface damage, helping to prevent unexpected failures.

- Quality assurance by identifying improperly positioned items, foreign materials, or surface defects.

- Increased workplace safety, reducing the risk of accidents caused by belt malfunctions or misalignments.

- Operational continuity, minimizing unplanned downtime through timely maintenance interventions.

However, traditional inspection methods, which rely on manual oversight, fall short in meeting the demands of high-speed, high-volume production environments.

Challenges of Manual Conveyor Belt Inspection

Manual inspection of conveyor belts presents a range of operational drawbacks that can severely impact production quality and efficiency. These limitations become increasingly apparent in fast-paced and high-volume manufacturing environments:

- Labor-Intensive and Time-Consuming

Manual inspections require skilled personnel for routine checks, increasing operational costs and diverting resources from critical tasks. - Inconsistency and Operator Dependency

Human-led inspections are subjective and prone to errors due to factors like fatigue, varying skill levels, and lapses in concentration. - Low Inspection Frequency

Manual inspections occur at scheduled intervals, creating gaps where defects may go unnoticed, leading to potential equipment failure or compromised quality. - Limited Accessibility in Complex Environments

In high-speed or hazardous environments, manual inspections are impractical or unsafe, limiting coverage and increasing the risk of undetected defects. - Scalability Issues in High-Throughput Facilities

As production increases, manual inspection becomes inefficient and unsustainable, requiring additional personnel and infrastructure that may not be feasible.

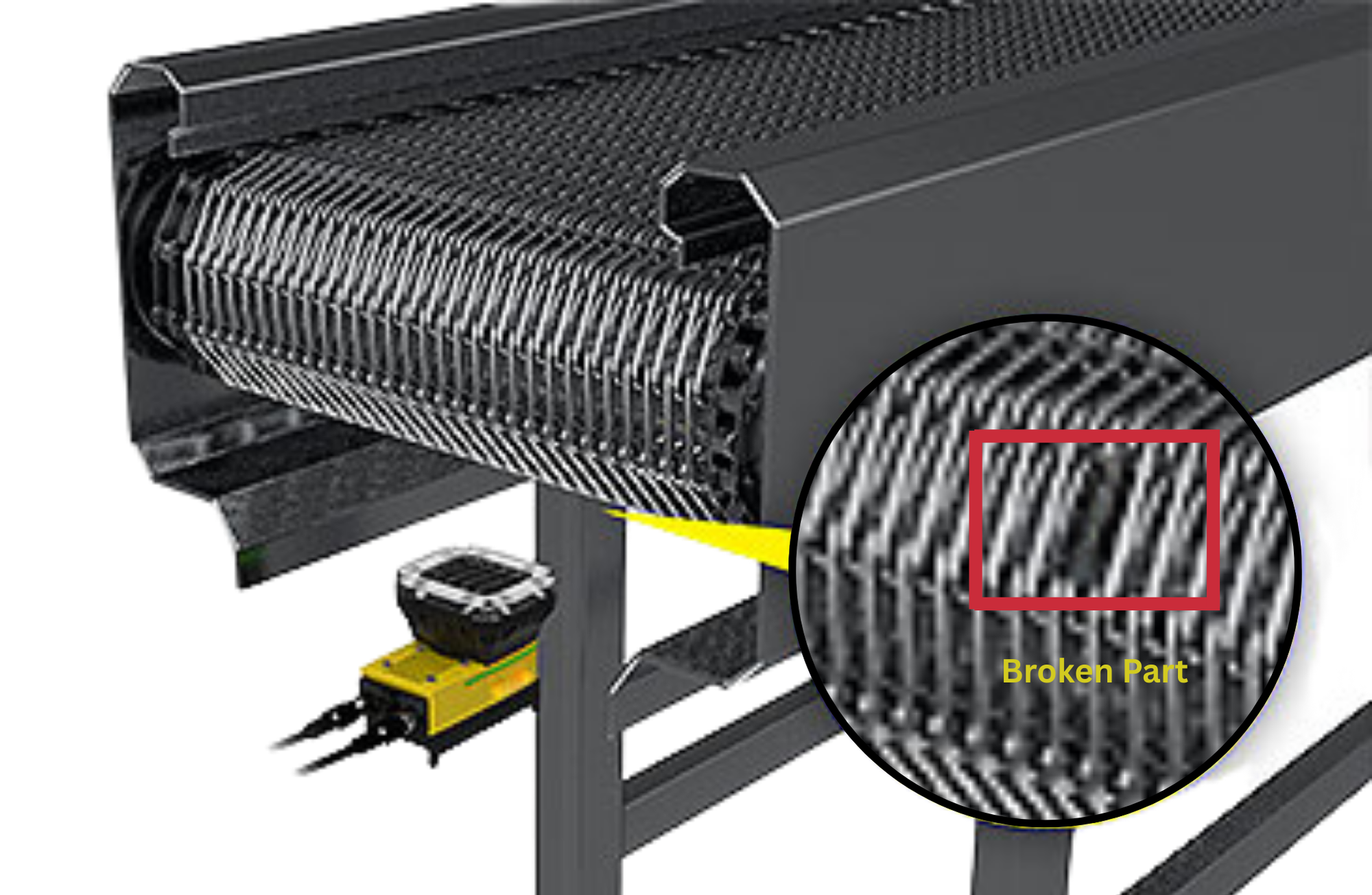

Machine Vision AI: A Smarter Approach to Conveyor Belt Inspection

Modern manufacturing environments demand precision, speed, and consistency—especially in the inspection of diverse and customized conveyor belt systems. To meet these specialized requirements, manufacturers are adopting tailored Machine Vision AI inspection systems engineered to match the unique characteristics of each conveyor setup. These intelligent systems combine industrial grade high resolution machine vision cameras, robotic arms, advanced illumination configurations, and real-time AI analytics to create customized inspection solutions. Whether used on flat, modular, inclined, curved, or specially designed conveyor belts, the system ensures highly accurate, scalable defect detection and real-time alerting.

1. Industrial-Grade High-Resolution Machine Vision Camera Systems

Industrial-grade high-resolution machine vision cameras form the core of the inspection system. These cameras are strategically placed along the conveyor to capture crystal-clear images of components and materials in motion, ensuring precise and uninterrupted inspection. Key advantages include:

- Seamless, high-speed imaging without motion blur, perfectly synchronized with conveyor movement for real-time analysis

- Accurate detection of critical conveyor belt defects, such as surface wear, cracks, cuts, splice misalignment, edge fraying, material buildup, surface delamination, holes, and foreign object intrusion

- Exceptional image clarity and resolution, allowing reliable inspection of complex surfaces and small defects

- Superior image stitching and coverage, ensuring no gaps in inspection across long or wide conveyor systems

- Flexible integration with various conveyor types, including flat, modular, inclined, and curved designs

- High-resolution cameras capture every detail with precision — no nut, bolt, gear shaft, damper, or steering rod escapes scrutiny. It's like having a hawk eye monitoring each component as the conveyor moves.

2. Advanced Illumination Systems

Effective lighting is essential for high-accuracy vision inspection. Advanced illumination systems—including backlighting, diffuse ring lights, directional LED Bars—are employed to enhance image clarity and contrast. These systems help:

- Eliminate shadows and reduce reflections on shiny or irregular surfaces

- Enhance defect visibility under varying ambient light conditions

- Improve detection consistency on reflective, transparent, or textured materials

3. Robotic Arms for Dynamic Inspection

In complex or hard-to-access inspection zones, robotic arms equipped with vision modules provide dynamic, flexible imaging. These robotic systems are particularly useful for:

- Accessing multiple viewing angles or hidden surfaces

- Aligning precisely with moving or irregular-shaped products

- Coordinating with conveyor flow for synchronized inspection

4. Real-Time AI Software and Defect Analysis with Intelligent Alerting

At the heart of the inspection system is a powerful real-time AI software platform that processes image data from cameras or robotic arms using advanced machine learning algorithms. These algorithms are trained on diverse, production-specific datasets to recognize a wide range of defects with high accuracy, including:

- Surface anomalies such as cracks, cuts, and abrasions

- Misalignments or orientation errors

- Missing components or improper assembly

- Contamination or presence of foreign objects

Once a defect is detected, the system immediately initiates an intelligent alert mechanism. This multi-layered alerting process ensures that operators and control systems are notified without delay:

- Visual and Audio Alarms: Flashing lights and sound signals at the inspection station notify nearby personnel of the issue.

- HMI Dashboards and Control Panels: The defect is displayed in real-time on operator screens with images, defect type, and location.

- Automated Messages: Alerts are sent via integrated systems such as SCADA, MES, or even SMS/email notifications for remote visibility.

- Action Triggers: Depending on configuration, alerts can also activate automatic rejection mechanisms (e.g., diverter arms) or temporarily halt the conveyor.

Conveyor Belt Inspection Workflow: A Step-by-Step Overview

The AI-powered conveyor belt inspection system is meticulously designed for maximum efficiency, precision, and scalability. Leveraging multiple area scan cameras, robotic arms, and real-time AI analysis, this system offers unparalleled defect detection across varied and complex conveyor setups, ensuring seamless operation in diverse manufacturing environments.

1. Image Acquisition

A network of strategically placed industrial grade high-resolution machine vision cameras captures continuous, crystal-clear images synchronized with the movement of the conveyor, ensuring complete surface coverage along the belt's direction. For particularly complex setups, robotic arms equipped with vision modules are deployed to dynamically adjust inspection angles and gather detailed data from hard-to-reach or irregular surfaces. This approach ensures precise, full-length inspection and supports comprehensive, high-consistency defect detection across all visible areas.

2. Image Preprocessing

Once the images are captured, advanced preprocessing techniques are applied to optimize data quality. The system performs noise reduction, edge enhancement, and contrast normalization to refine image clarity, ensuring the detection of even the smallest defects. This stage ensures that lighting inconsistencies and product variations do not hinder the inspection process.

3. AI-Based Analysis

The preprocessed images are fed into the real-time AI analysis engine, where sophisticated machine learning models are used to compare each image frame against defect profiles. These AI models, trained with industry-specific datasets, are designed to identify a broad spectrum of defects, from minor abrasions to major misalignments, in real-time. The analysis leverages both static camera images and dynamic robotic arm data, enabling thorough inspection of complex or moving products.

4. Defect Detection and Classification

Upon detecting a defect, the system automatically categorizes the anomaly into predefined classes, such as:

- Surface defects: scratches, cracks, or material tears

- Alignment issues: misalignments or positioning errors

- Contaminants: foreign objects or debris

- Missing components: improperly applied labels, seals, or packaging

- Product deformation: warped or incorrectly shaped items

5. Alert Generation and Operator Notification

Once a defect is confirmed, the system promptly generates real-time alerts to notify operators and quality control personnel:

- Visual alerts on operator dashboards, featuring annotated images and defect specifics

- Audible alarms or flashing indicators at designated checkpoints on the production line

- Automated notifications sent to supervisory systems (e.g., SCADA, MES) or directly to operators via mobile alerts

These notifications provide key information such as defect severity, timestamp, and location, enabling swift corrective actions to be taken.

6. Data Logging and Reporting

All detected defects, along with their associated data (e.g., timestamp, location, type, severity), are logged and stored in a centralized database. This data provides valuable insights for:

- Traceability and auditing

- Performance analysis to identify recurring issues or inefficiencies

- Predictive maintenance by analyzing trends and preemptively addressing potential failures before they escalate

7. Optional Actuation for Automated Quality Control

In advanced configurations, the inspection system can be integrated with robotic arms or diverters to automatically remove defective products from the production line. This proactive approach ensures that defective items do not continue through the production process, maintaining the flow of quality products and preventing costly errors.

Intelgic's Expertise in Conveyor Inspection

Intelgic’s Live Vision AI Platform stands as a pinnacle of innovation and expertise in the field of conveyor belt inspection. With a comprehensive and scalable solution, it is tailored to meet the unique demands of modern manufacturing environments, offering:

- Edge and cloud-based processing, providing manufacturers with the flexibility to choose the ideal deployment method. This ensures real-time processing at the edge for quick decision-making, while cloud integration supports data analytics and centralized control.

- Seamless on-site and remote deployment, ensuring that the system adapts to both secure local environments and distributed setups, offering versatile implementation options regardless of facility type or location.

- AI models custom-trained on real-world production data, which allows the system to achieve exceptional accuracy in defect detection, understanding the intricacies and nuances of the manufacturing process. This ensures reliable and precise identification of even the most subtle defects.

- Cross-platform compatibility, designed to smoothly integrate with existing hardware or facilitate gradual upgrades, making the transition to advanced AI-driven inspection systems cost-effective and scalable.

- Intuitive, user-friendly dashboards, giving operators clear, actionable insights into inspection performance and defect trends, enhancing decision-making and process optimization.

Leveraging Intelgic’s deep expertise, manufacturers can significantly reduce downtime, boost product quality, and ensure full compliance with industry standards—all while maintaining high throughput and maximizing operational efficiency.

As manufacturing ecosystems evolve toward Industry 4.0, the adoption of intelligent inspection systems is no longer a luxury—it is a necessity. Traditional manual methods simply cannot keep pace with the speed, complexity, and precision required in today’s competitive landscape.

With its tailored Machine Vision AI technology, Intelgic is redefining the standards of conveyor belt inspection—enabling manufacturers to achieve higher reliability, lower operational risks, and faster responses to quality issues. Through real-time monitoring, automated alert systems, and deep integration with factory automation, Intelgic empowers industries to move confidently into the future of smart, self-optimizing production.

Connect with Intelgic today to integrate advanced AI-driven vision systems for real-time, automated conveyor inspection that ensures precision and operational efficiency.