Highly Reflective Automobile Machine Part Inspection Automation Using Machine Vision AOI

Published on: Apr 15, 2025

Written by: Content team, Intelgic

Highly Reflective Automobile Machine Part Inspection Automation Using Machine Vision AOI

In the fast-paced world of automotive manufacturing, precision, speed, and consistency are non-negotiable. Among the most demanding inspection tasks in this sector is the inspection of highly reflective automobile machine parts, such as chrome-plated engine components, polished shafts, gears, and metallic housings. These parts play critical roles in vehicle performance and safety and must meet stringent quality standards. However, due to their reflective surfaces, they pose unique challenges during inspection—especially when using conventional optical methods.

To address these complexities, Machine Vision Automated Optical Inspection (AOI) has emerged as a robust solution. Enhanced with AI software, line scan cameras, and darkfield illumination techniques, machine vision systems offer real-time, high-accuracy defect detection tailored for shiny, mirror-like automotive components.

Common Defects in Manufacturing of Highly Reflective Automobile Parts

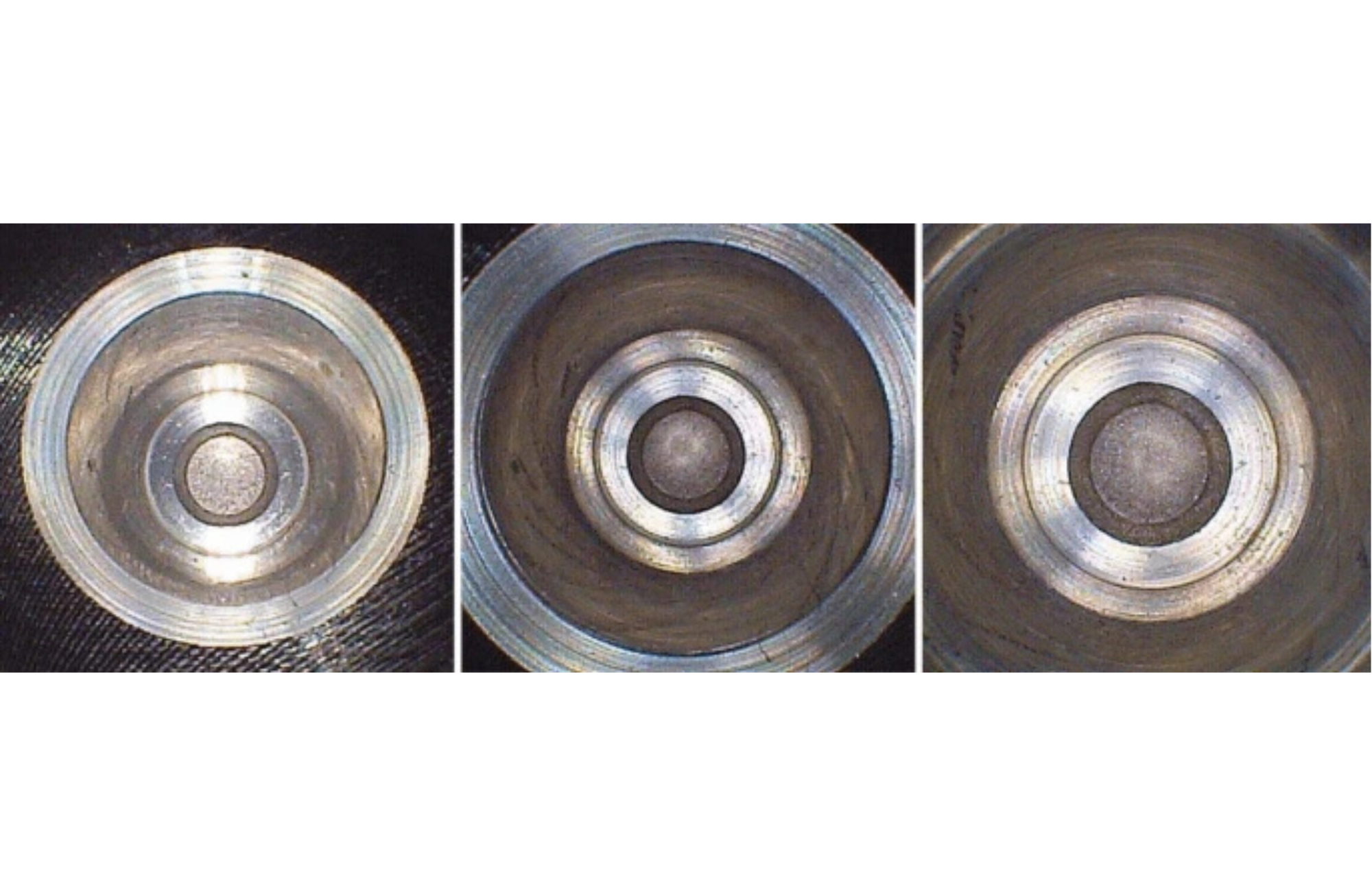

In automotive manufacturing, the production of highly reflective machine parts—such as polished shafts, camshafts, valves, gear housings, and plated engine components—involves precision machining, grinding, polishing, and coating processes. Each of these stages introduces a risk of surface-level and structural imperfections. Below are some of the most common manufacturing-related defects that require automated inspection:

- Surface Scratches and Abrasions: Caused during polishing, grinding, or part handling. Even micro-level scratches can affect surface integrity and reflectivity.

- Tool Marks: Residual patterns from machining tools or improper tool paths, often invisible to the naked eye but critical for high-precision components.

- Burn or Heat Marks: Overheating during machining or finishing can leave discoloration or microstructural changes on reflective surfaces.

- Burrs and Sharp Edges: Incomplete deburring during milling or drilling can leave sharp projections, posing assembly and safety risks.

- Pitting and Pinholes: Minute depressions or cavities caused by casting issues, contamination, or chemical reactions during plating or coating.

- Coating Defects: Irregularities like peeling, blistering, uneven thickness, or orange peel texture on chrome or nickel-plated surfaces.

- Cracks (Micro or Macro): Stress-induced or fatigue-related cracks formed during heat treatment, press-fitting, or due to material weaknesses.

- Surface Deformation or Warping: Due to improper clamping, thermal expansion, or mechanical stress during the manufacturing process.

- Contaminants and Foreign Particles: Residues from lubricants, polishing compounds, dust, or metallic particles that affect both performance and appearance.

Challenges in Inspecting Highly Reflective Surfaces

Automated inspection of reflective metal parts introduces a set of challenges not typically encountered with matte or low-reflectivity surfaces:

- Glare and Hotspots: Light sources reflected off smooth, shiny surfaces can create intense glare, blinding the camera sensor and obscuring surface features.

- Inconsistent Reflections: Slight differences in part orientation or lighting angle can drastically alter how the surface appears, making consistent imaging difficult.

- False Positives/Negatives: Reflections and ambient lighting changes can trick standard vision systems, leading to misclassification of good parts as defective or vice versa.

- High Surface Curvature: Parts with complex shapes reflect light unevenly, requiring more sophisticated illumination and imaging techniques.

To overcome these, specialized hardware and software must work in tandem, enabling reliable defect detection under challenging conditions.

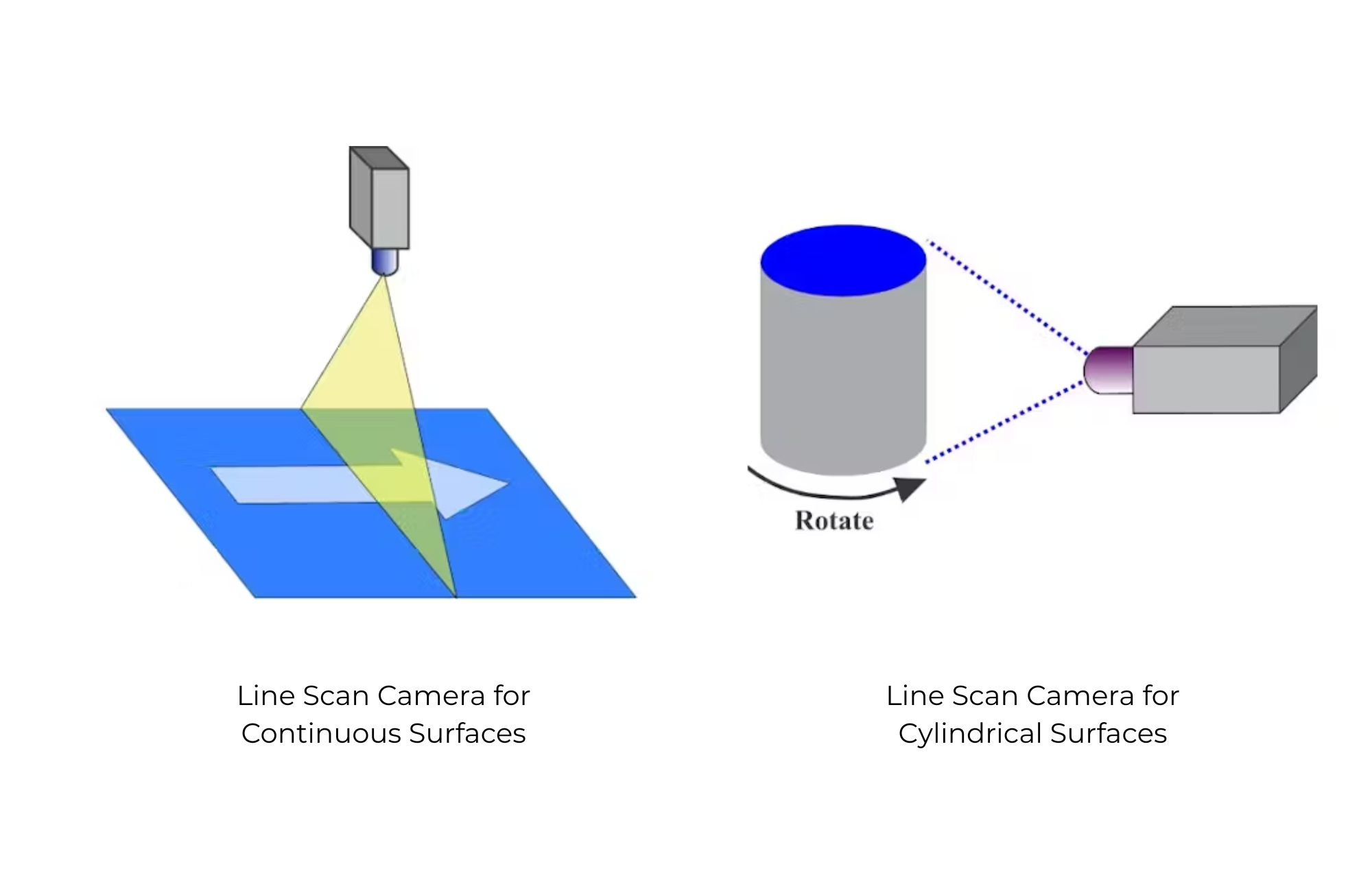

Line Scan Cameras: Ideal for Cylindrical and Continuous Surfaces

Line scan cameras are particularly well-suited for inspecting reflective surfaces, especially on cylindrical or elongated parts like shafts, rollers, and gear housings. Unlike area scan cameras that capture an entire image in one shot, line scan cameras acquire images one line at a time as the part moves through the field of view or rotates.

Advantages of Line Scan Imaging:

- High Resolution: Extremely fine defect detection thanks to dense line acquisition.

- Minimized Reflection Artifacts: Controlled lighting and narrow field of view reduce glare.

- Ideal for Continuous Motion: Perfect for inline inspection of rotating or linearly moving parts.

By integrating line scan imaging with motion control systems, manufacturers can inspect 100% of a part’s surface area in real-time.

Darkfield Illumination: Enhancing Surface Defect Visibility

Traditional brightfield lighting often fails with reflective parts due to overwhelming glare. This is where darkfield illumination becomes a game-changer.

What is Darkfield Illumination?

Darkfield lighting positions the light source at a very low angle to the part’s surface. This setup means that only light scattered by surface irregularities (like scratches or dents) enters the camera, while flat, defect-free areas appear dark.

Benefits:

- Enhanced Contrast for Defects: Surface imperfections stand out clearly.

- Reduced Background Noise: Eliminates unnecessary reflections from smooth areas.

- High Sensitivity: Can detect minute flaws invisible to brightfield systems.

Darkfield illumination, especially when combined with line scan cameras, creates high-contrast images ideal for AI-driven defect detection on shiny surfaces.

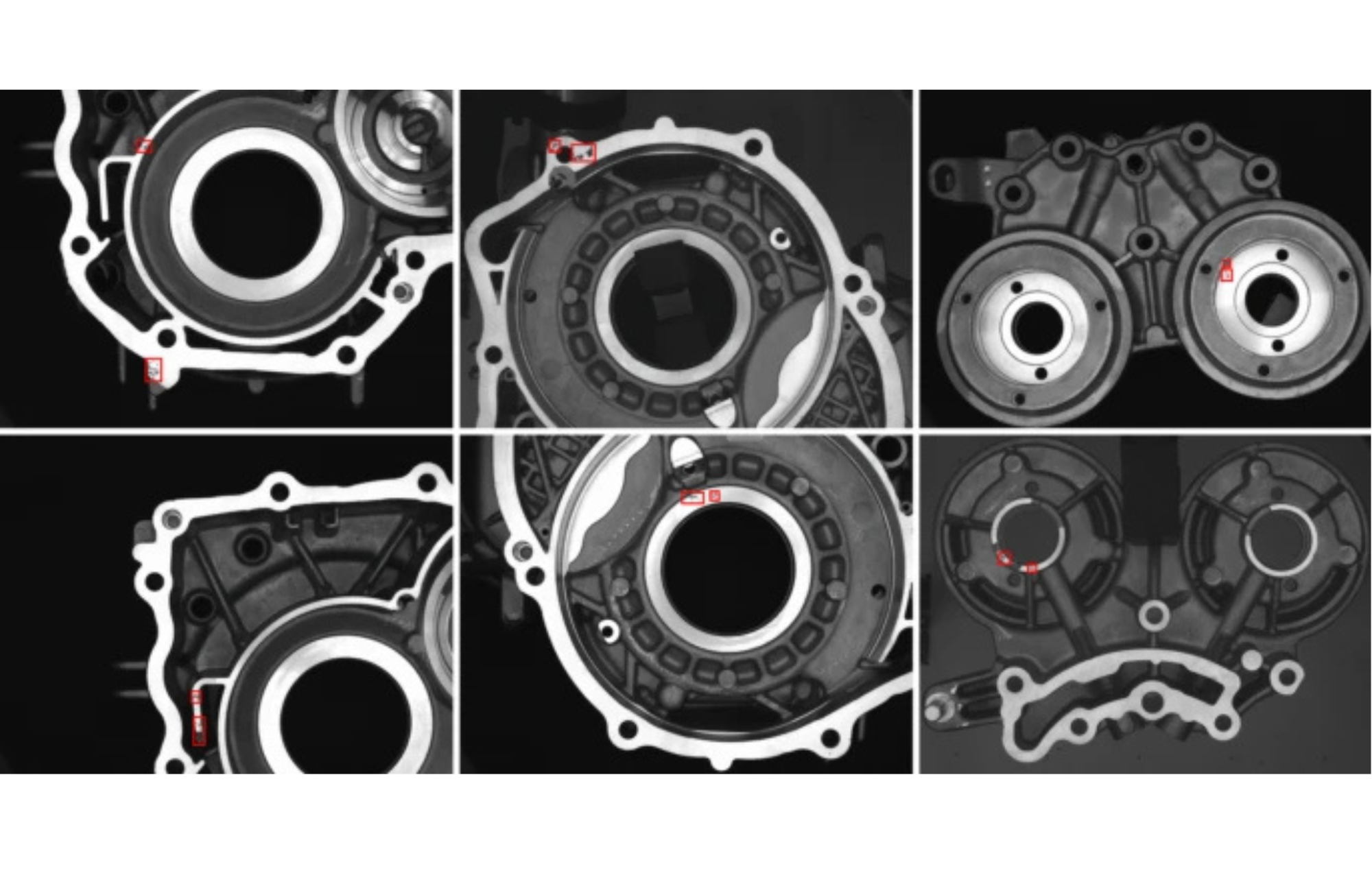

AI-Powered Real-Time Inspection Software

While cameras and illumination handle image acquisition, AI-driven inspection software is the brain that interprets the data. Traditional rule-based image processing struggles with the subtlety and variability of reflective part defects. AI models, particularly those based on deep learning, offer superior flexibility and accuracy.

Features of AI Inspection Software:

- Real-Time Decision Making: Classifies defects instantly for fast line response.

- Continuous Learning: Improves over time by learning from new defect patterns.

- Multiple Defect Detection: Can detect, classify, and quantify several defect types in a single image.

- Adaptive to Variability: Tolerates part-to-part variation and noise better than traditional systems.

By using AI to process visual data, manufacturers gain not only speed but also a powerful ability to reduce false positives, track defect trends, and improve production processes.

Workflow of the Machine Vision AOI System for Reflective Parts

Here’s how a typical automated inspection system for reflective automotive components works:

- Part Positioning & Movement:

- Parts are fed into the inspection zone via conveyor or robotic arms.

- For cylindrical parts, a rotation mechanism may be used to expose the entire surface.

- Parts are fed into the inspection zone via conveyor or robotic arms.

- Imaging Setup:

- Line scan camera captures high-resolution line images.

- Darkfield lighting illuminates the part from low angles to highlight surface defects.

- Line scan camera captures high-resolution line images.

- Image Acquisition:

- As the part rotates or moves, the system acquires a full 2D or even 3D image of the surface.

- As the part rotates or moves, the system acquires a full 2D or even 3D image of the surface.

- AI-Based Processing:

- Images are analyzed in real time using deep learning models trained to identify a wide range of defects.

- Images are analyzed in real time using deep learning models trained to identify a wide range of defects.

- Defect Classification & Action:

- Detected flaws are classified (e.g., scratch, pit, contamination).

- System flags defective parts and communicates with downstream systems for ejection, repair, or sorting.

- Detected flaws are classified (e.g., scratch, pit, contamination).

- Reporting and Traceability:

Data is logged for quality control reports, traceability, and continuous improvement.

Advantages of Machine Vision AOI for Highly Reflective Automobile Parts

Automating the inspection of reflective automotive parts with machine vision AOI systems brings several key benefits to modern manufacturing:

1. High Precision and Consistency

Machine vision systems detect microscopic defects like scratches, pits, and coating flaws with unmatched accuracy. Unlike human inspectors, they maintain consistent performance 24/7 without fatigue or variation.

2. Real-Time Defect Detection

These systems provide instant feedback, enabling immediate rejection of faulty parts or alerts for process adjustments. This reduces the chances of defective components moving further down the line.

3. Fewer False Positives

AI models distinguish between true defects and harmless surface variations, reducing false rejections and minimizing rework or scrap, saving both time and cost.

4. Complete Surface Coverage

Using line scan cameras and controlled part movement, AOI systems capture 100% of the surface—even on cylindrical or complex-shaped parts—ensuring no defect is missed.

5. Actionable Data and Traceability

Each inspection generates detailed reports with defect classification and images. This supports root cause analysis, trend monitoring, and compliance with quality standards.

6. Reduced Labor Dependence

By automating inspection, manufacturers reduce reliance on manual inspectors, lowering training costs and improving overall operational efficiency.

7. Easy Integration and Scalability

Machine vision AOI systems are modular, flexible, and designed for seamless integration into existing production lines—scaling easily as manufacturing needs grow.

Intelgic’s Expertise in Reflective Part Inspection Automation

Intelgic has emerged as a pioneer in providing intelligent, AI-driven inspection solutions for the most demanding manufacturing environments. Leveraging Live Vision, Intelgic’s proprietary machine vision platform, the company has helped several automotive suppliers automate the inspection of highly reflective machine parts with exceptional precision.

Why Intelgic?

- Expertise with Reflective Surfaces: Intelgic’s team understands the nuances of inspecting polished and plated parts, using a blend of darkfield, coaxial, and structured light techniques.

- Customized Solutions: Systems are tailored to the customer’s parts, inspection criteria, and factory workflow.

- Advanced AI Models: Trained on real-world defect datasets and continually refined with new production images.

- Integration Ready: Intelgic’s solutions seamlessly integrate with existing PLC, SCADA, MES, and robotic systems.

- Scalable and Future-Proof: Built to evolve with production changes, new parts, and evolving defect types.

Intelgic also provides end-to-end implementation support, including camera selection, lighting design, AI model training, system integration, and post-deployment monitoring.

Conclusion

The inspection of highly reflective automobile machine parts demands a sophisticated, multi-layered approach. Traditional manual or basic machine vision systems often fall short due to the complexity of lighting, reflections, and subtle defects.

Machine Vision AOI, powered by line scan cameras, darkfield illumination, and AI-based inspection software, offers a reliable and scalable solution to these challenges. With benefits ranging from higher defect detection rates to consistent 24/7 operation, the return on investment is clear for forward-thinking automotive manufacturers.

Intelgic brings unmatched expertise in this niche, helping companies automate inspection processes with intelligent, adaptable, and high-performance solutions. As the automotive industry pushes for higher quality standards and digital transformation, Intelgic’s innovations stand at the forefront of a smarter, more efficient future in machine part inspection.