Computer vision AI in SOP monitoring in Manufacturing

Published on: Nov 08, 2024

Written by: Soumen das

How Computer Vision AI is Transforming SOP Monitoring in Manufacturing

The manufacturing industry is continually evolving, with significant advancements in automation and artificial intelligence (AI) playing a central role in improving productivity and safety. One of the latest applications of AI, specifically computer vision, is in the monitoring of Standard Operating Procedures (SOPs) in manufacturing. This technology enables organizations to automate the oversight of each manufacturing process, ensuring adherence to SOPs and quickly identifying any deviations.

SOP Monitoring in Manufacturing

Standard Operating Procedures (SOPs) are detailed instructions designed to ensure that processes in manufacturing are carried out consistently and correctly. These procedures define the quality, safety, and efficiency standards for each step of production, from material handling to assembly, inspection, and packaging. Traditionally, SOP monitoring in manufacturing relied heavily on human oversight, making it prone to errors and inconsistencies.

With recent advancements in AI and computer vision, manufacturers now have the potential to automate SOP compliance checks, leveraging cameras and AI algorithms to monitor tasks in real-time. This shift allows for continuous and objective monitoring, ensuring adherence to SOPs, reducing human error, and enhancing overall operational efficiency.

How Computer Vision AI Works in SOP Monitoring

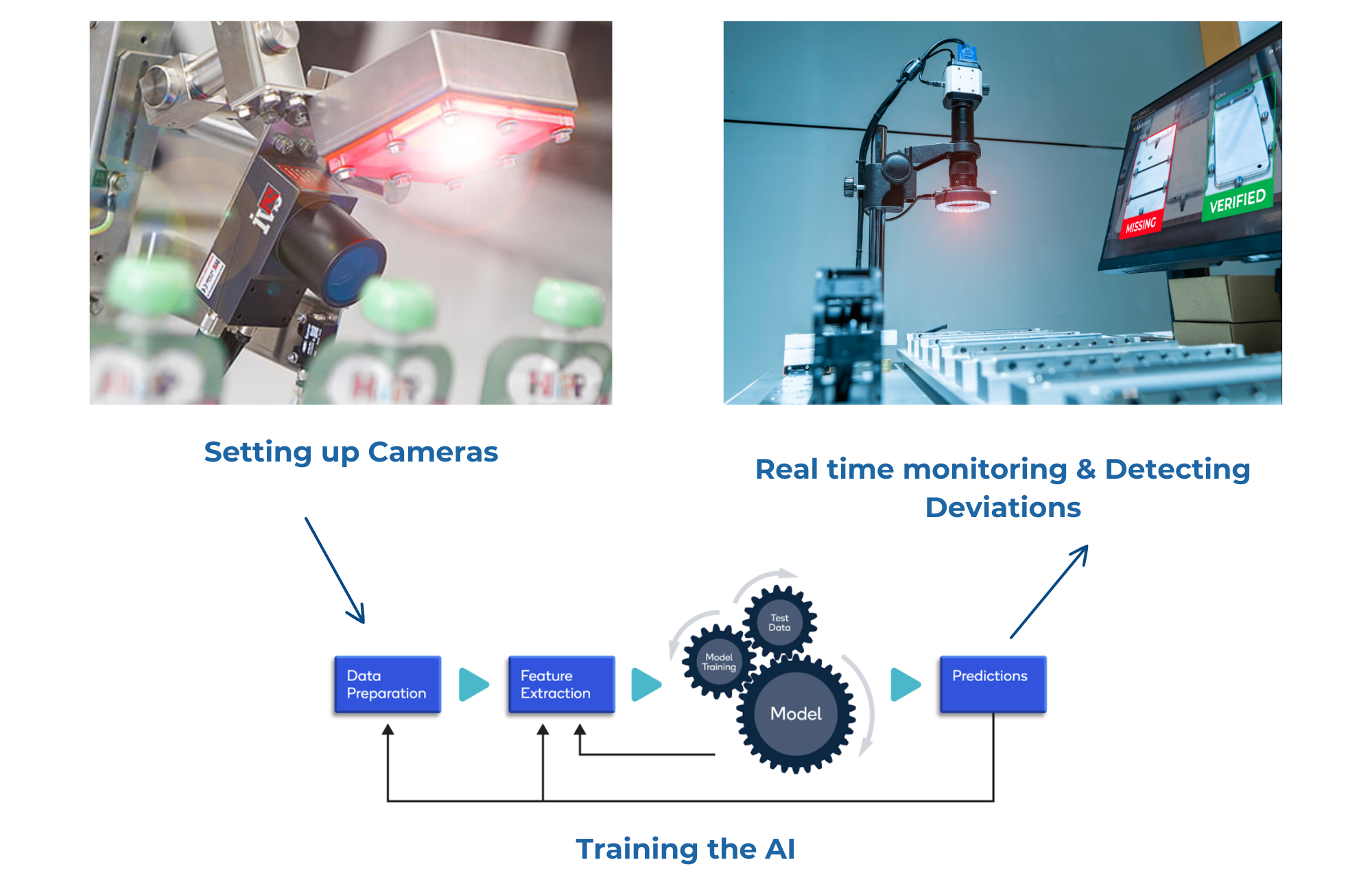

Computer vision AI relies on cameras and image recognition algorithms to interpret visual data from the production floor. Here’s a step-by-step breakdown of how this technology can be used to monitor SOPs:

- Setting up Cameras – Cameras are strategically placed throughout the production area to capture each stage of the manufacturing process. These cameras continuously stream real-time video footage.

- Training the AI – The AI is trained on the specific steps required in the SOP. For example, if a worker needs to follow a particular sequence when assembling parts, the AI learns to identify each of these actions.

- Real-Time Monitoring – Once trained, the AI analyzes live footage, comparing the actions on the floor to the expected actions as defined in the SOP. By detecting gestures, positions, and objects, the AI can verify whether each step is followed correctly.

- Detecting Deviations – If any deviation from the SOP is detected, such as incorrect assembly sequence or a skipped quality check, the AI raises an alert. This alert can notify a supervisor or stop the process to prevent errors from progressing down the production line.

Key Applications of Computer Vision AI in SOP Monitoring

Computer vision AI can enhance multiple aspects of SOP monitoring across different stages of manufacturing:

- Quality Control: By monitoring assembly and production stages, AI can detect product defects early. For example, it can identify if parts are misaligned or incorrectly positioned, ensuring that quality standards are met.

- Packaging Inspection: During packaging, AI can monitor any missing components or parts that go into the final package preventing any mistake during the packaging. This leads to minimizing the customiser dissatisfaction, costly returns and smoothening the installation process.

- Safety Compliance: AI can monitor for safety violations, such as workers failing to wear personal protective equipment (PPE) or handling materials improperly. If unsafe behavior is detected, the AI can trigger an alert to address it immediately.

- Process Flow Verification: In multi-step manufacturing processes, AI can monitor the sequence of operations, ensuring that workers follow the correct order and timing of tasks. This prevents issues that can arise from improper or missed steps in the production flow.

- Inventory and Material Handling: AI can track materials and components across the floor, ensuring that each item is in the correct place. For instance, if a worker picks up the wrong part, the AI can immediately flag it, reducing potential errors.

- Automated Documentation: AI-based monitoring can automatically log compliance data, creating an audit trail for each production run. This is especially beneficial in highly regulated industries where documentation of SOP compliance is mandatory.

Benefits of Using Computer Vision AI for SOP Monitoring

Implementing computer vision AI for SOP monitoring brings several advantages to manufacturing operations:

a) Increased Accuracy and Consistency

By removing the human element from SOP monitoring, computer vision AI ensures that compliance checks are conducted objectively and consistently. This reduces the likelihood of human error, which is particularly valuable in repetitive and complex processes.

b) Real-Time Alerts and Quick Response

The ability to detect deviations in real-time allows for rapid intervention. For example, if a worker accidentally skips a step, the AI can send an alert immediately, preventing the mistake from affecting subsequent production stages.

c) Enhanced Safety and Risk Reduction

By monitoring safety protocols, computer vision AI helps minimize accidents and injuries on the production floor. Immediate alerts for unsafe actions enable supervisors to address issues before they escalate.

d) Cost Savings

Automated SOP monitoring can reduce costs associated with rework, scrap, and downtime by catching errors early in the production process. Additionally, by reducing human oversight requirements, companies can allocate resources more efficiently.

e) Improved Compliance and Traceability

Industries like pharmaceuticals, automotive, and electronics have strict regulatory requirements. Computer vision AI allows manufacturers to document compliance seamlessly, generating detailed reports that auditors and regulatory bodies can review.

Challenges in Implementing Computer Vision AI

While computer vision AI offers significant benefits, there are challenges to consider:

a) Complex Setup and Training

The initial setup and training of computer vision AI systems can be complex and time-consuming. Each manufacturing process is unique, and the AI needs to be trained on specific SOPs to accurately identify compliance or deviation.

b) Data Privacy and Security

Using cameras on the production floor raises concerns about worker privacy. Manufacturers must ensure that the data captured is secure and that AI systems adhere to privacy regulations.

c) Adaptability to Changes in SOPs

Manufacturing processes and SOPs evolve over time, which requires retraining the AI system to recognize new steps or procedures. Regular updates and maintenance are essential for the AI to remain effective.

d) Cost of Implementation

While computer vision AI can save costs in the long run, the initial investment can be substantial, particularly for small manufacturers. High-quality cameras, powerful computing resources, and skilled personnel are necessary to set up and maintain the system.

Future of SOP Monitoring with Computer Vision AI

The future of computer vision AI in manufacturing holds immense potential as advancements continue to make the technology more accessible, efficient, and intelligent. Here are some anticipated developments:

- Integration with IoT: Combining computer vision AI with Internet of Things (IoT) devices can provide comprehensive insights into each stage of the manufacturing process. IoT sensors can capture additional data, such as temperature or pressure, complementing visual monitoring for enhanced oversight.

- Predictive Analysis: AI systems could move from simply monitoring SOPs to predicting potential issues. For example, if a machine exhibits subtle signs of malfunction, the AI can detect this and alert operators to prevent a breakdown.

- Augmented Reality (AR) for Workers: AR glasses integrated with computer vision AI could guide workers through SOPs step-by-step, providing real-time feedback and alerts directly in their field of view.

- Advanced Robotics: AI-powered robots could not only perform tasks but also monitor themselves for SOP compliance, reducing the need for human oversight entirely.

Computer vision AI is revolutionizing SOP monitoring in manufacturing by providing real-time, accurate, and consistent oversight of processes. From quality control to safety and compliance, this technology enables manufacturers to maintain high standards while minimizing human error. Despite challenges, the benefits of computer vision AI are driving increased adoption across the industry, setting the stage for a future where SOP monitoring is seamlessly integrated with intelligent automation.

As computer vision AI technology continues to mature, we can expect even more sophisticated capabilities that will further transform manufacturing processes, enabling factories to operate with unprecedented precision, safety, and efficiency.