Why General-Purpose Cameras are Unsuitable for Defect Detection inspection automation and Machine Vision Solutions

Published on: Dec 05, 2024

Written by: Soumen das

Why only Machine Vision Cameras are used in anomaly Detection instead of General-Purpose Cameras such as IP Cameras, Mobile Cameras and Others

Defect detection and machine vision solutions are critical for ensuring quality control and process optimization in manufacturing. These applications demand precision, reliability, and consistency, which are characteristics that general-purpose cameras, such as IP cameras and mobile cameras, cannot deliver. While general-purpose cameras are versatile and designed for everyday use in photography, surveillance, or video streaming, they fall short in the specialized requirements of defect detection and machine vision.

1. General-Purpose Cameras are Area Scan Cameras, Unsuitable for Moving Lines

One of the primary reasons general-purpose cameras fail in defect detection is their area-scan design:

- How Area Scan Cameras Work:

General-purpose cameras capture a full 2D image in a single frame. While this is ideal for capturing still scenes, it is ineffective for high-speed production lines where materials are moving continuously. - Why Area Scan Cameras Fall Short:

In moving line inspections, area-scan cameras struggle to maintain image clarity due to motion blur, making it impossible to detect fine defects. Line-scan cameras, commonly used in machine vision, address this by capturing images line by line and stitching them together to form a high-resolution 2D image, enabling precise inspection of fast-moving materials.

2. General-Purpose Cameras Have Larger Pixel Sizes

- Impact of Pixel Size on Resolution:

General-purpose cameras, like those in smartphones or IP cameras, typically have larger pixel sizes. While this helps in low-light photography, it limits their ability to resolve fine details, which is critical in defect detection. - Why Small Pixels Matter in Machine Vision:

Machine vision cameras are designed with smaller pixel sizes, allowing them to capture more details within the same field of view. This is essential for detecting micron-level defects, such as scratches, cracks, or pinholes, which general-purpose cameras cannot resolve.

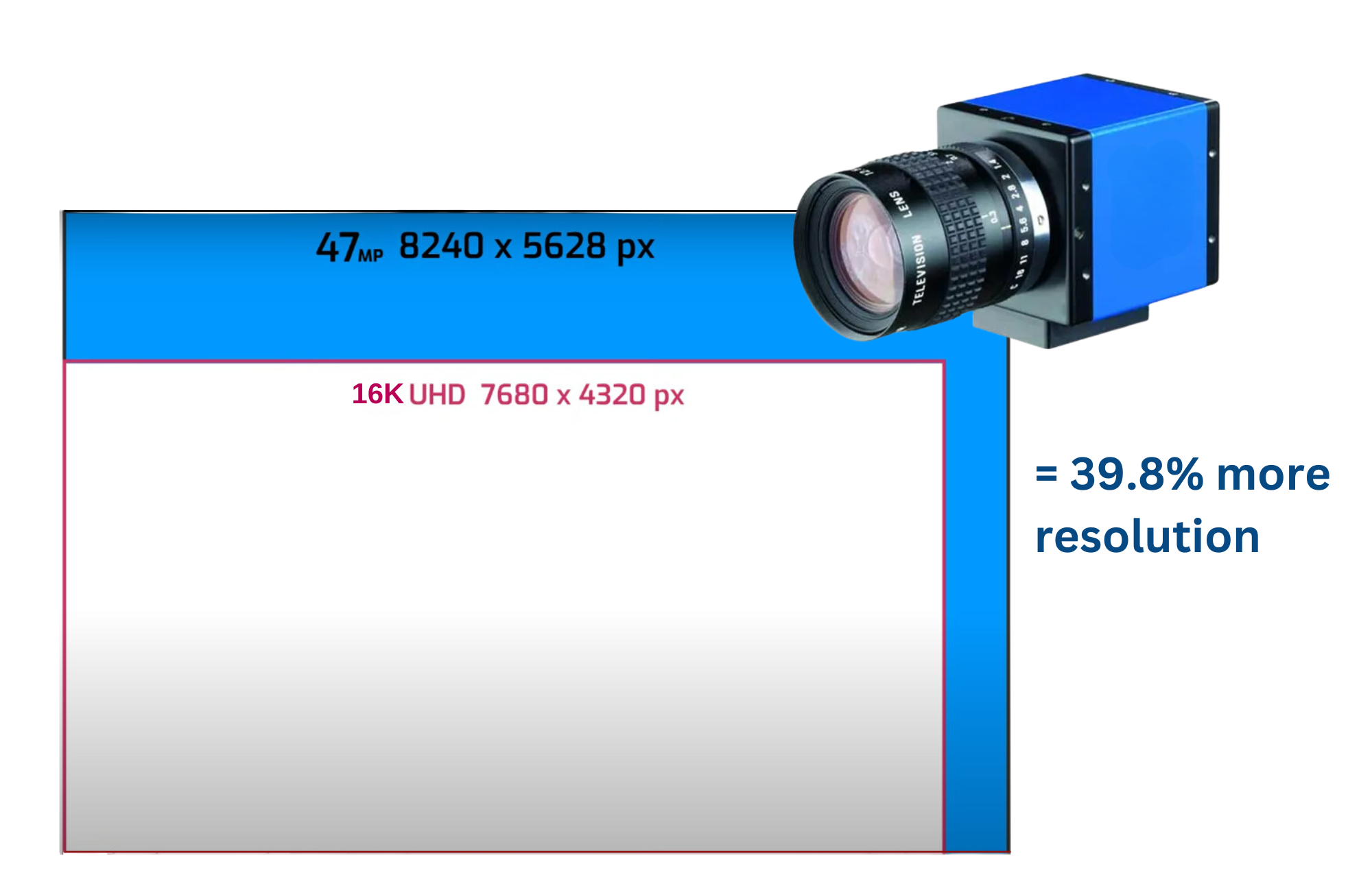

3. General-Purpose Cameras Have Lower Resolution

- Resolution in General-Purpose Cameras:

The resolution of general-purpose cameras is optimized for capturing overall scenes or large objects but lacks the granularity needed for industrial inspection. Even high-end IP cameras, which may boast resolutions like 4K, are insufficient for inspecting small defects on large surfaces. - High Resolution in Machine Vision Cameras:

Machine vision cameras are available with resolutions up to 16k or higher, making them ideal for inspecting intricate details on surfaces like films, foils, or automotive parts. This high resolution ensures that no defect, regardless of its size, goes undetected.

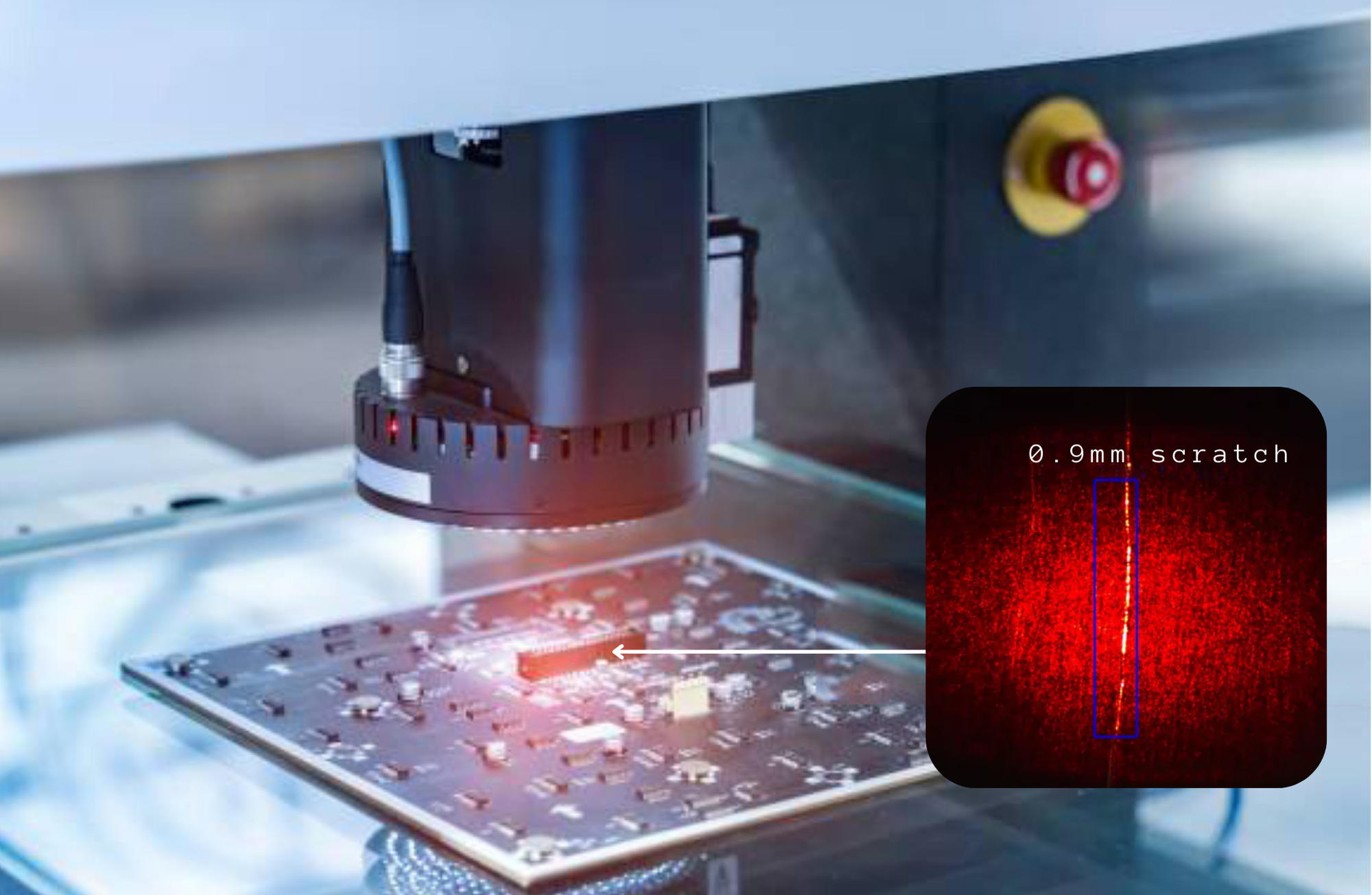

4. General-Purpose Cameras Lack the Detail Needed for Defect Detection

Defect detection requires capturing subtle variations in texture, or shape that general-purpose cameras are not designed to handle:

- Inadequate Image Clarity:

General-purpose cameras often fail to capture the level of detail needed for identifying small anomalies such as micro-cracks or surface roughness. - Machine Vision Cameras for Enhanced Detail:

Machine vision cameras are optimized for industrial use, offering enhanced image clarity and contrast, which are crucial for detecting minute defects.

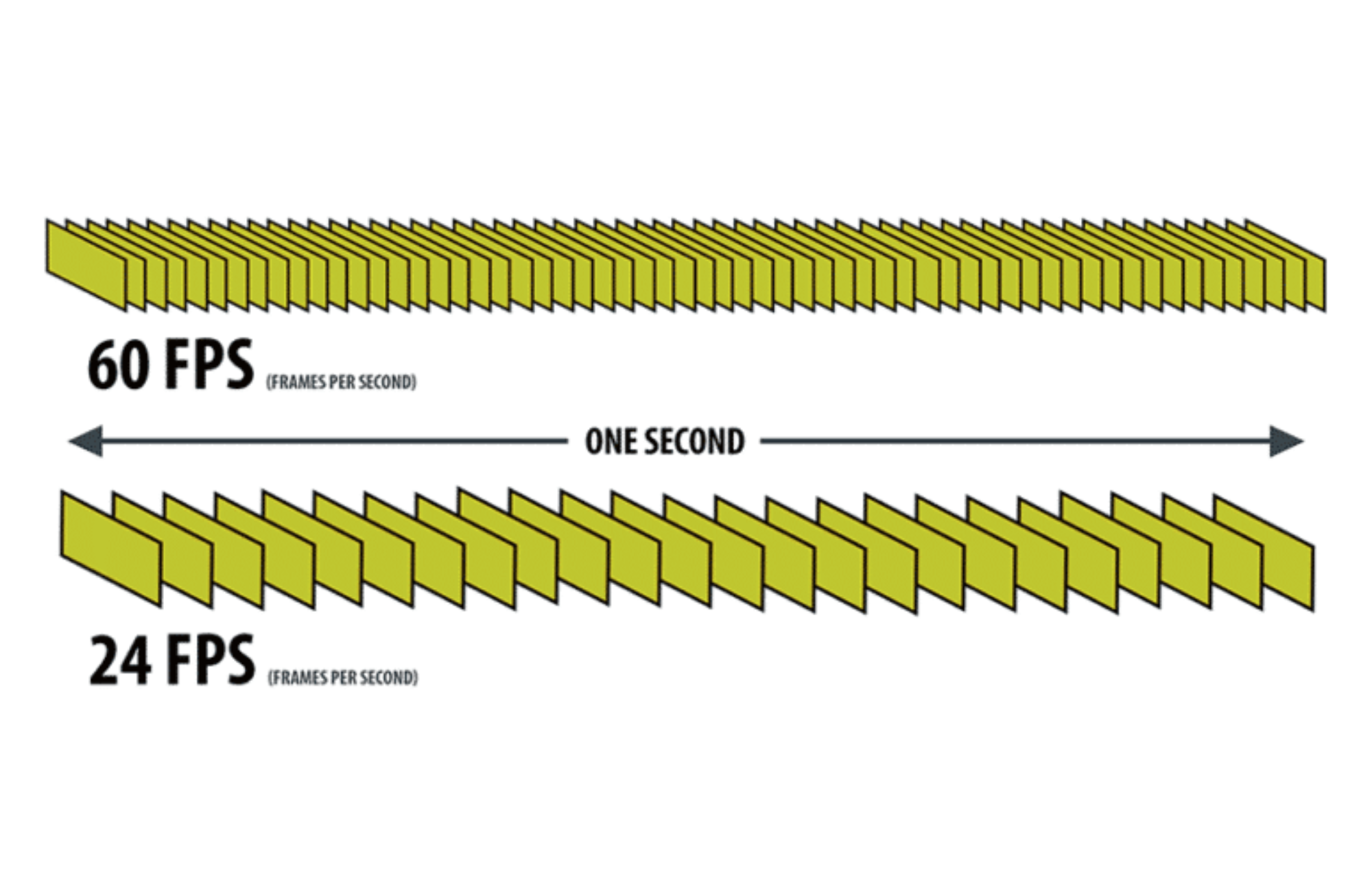

5. General-Purpose Cameras Have Higher FPS, Which is Not Needed

General-purpose cameras are designed for applications where high frame rates (FPS) are prioritized, such as video recording or surveillance:

- Unnecessary High FPS:

While general-purpose cameras may achieve 30 to 60 FPS or higher, such frame rates are unnecessary for inspection automation, where precision is more important than speed. - Optimized FPS in Machine Vision Cameras:

Machine vision cameras operate at frame rates optimized for industrial inspections, ensuring that every frame is sharp, detailed, and aligned with the movement of the production line.

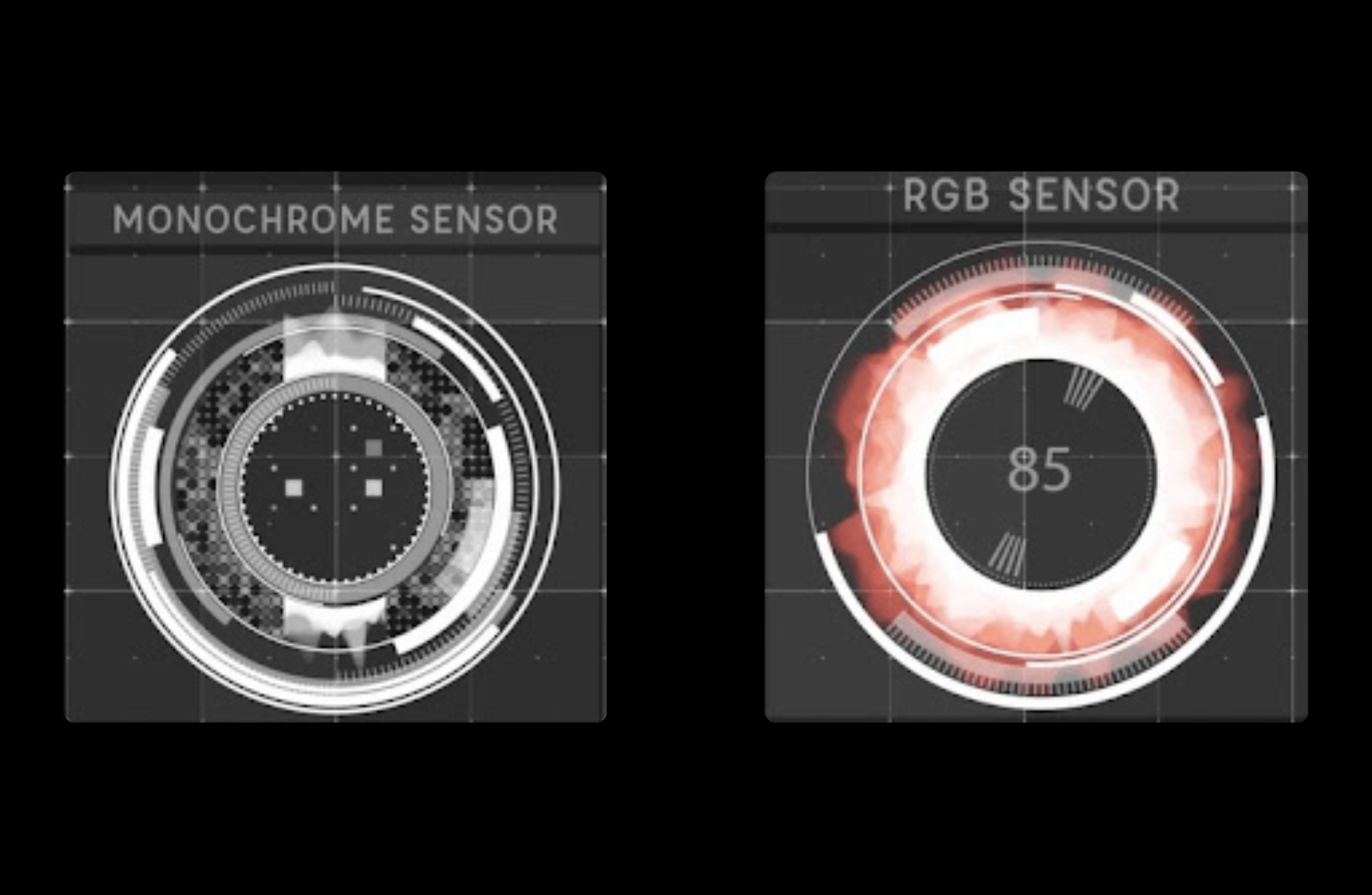

6. Machine Vision Cameras Use Monochrome Sensors for Better Contrast

General-purpose cameras are designed to capture color images, which, while suitable for everyday photography, are not ideal for defect detection:

- Why Monochrome is Better:

Machine vision cameras often use monochrome sensors, which capture images without color filters. This results in higher resolution and better sensitivity, particularly in low-light conditions. - Enhanced Contrast for Defect Detection:

Monochrome images provide superior contrast, making it easier to detect fine details and defects like scratches, dents, or cracks. This is particularly important when inspecting materials with complex textures or reflective surfaces.

Advantages of Machine Vision Cameras Over General-Purpose Cameras

|

Feature |

General-Purpose Cameras |

Machine Vision Cameras |

|

Design |

Area Scan (Full Frame) |

Line Scan or Area Scan (Specialized for Industrial Use) |

|

Pixel Size |

Larger (Lower Detail) |

Smaller (Higher Detail) |

|

Resolution |

Limited (Up to 4K) |

High (Up to 16K or Higher) |

|

Detail |

Limited for Defect Detection |

Enhanced Detail for Micron-Level Defects |

|

Frame Rate |

High FPS (Unnecessary for Inspections) |

Optimized for Inspection Speed |

|

Sensor Type |

Color |

Monochrome (Better Contrast) |

|

Applications |

General Photography, Surveillance |

Industrial Inspection, Defect Detection |

While general-purpose cameras like IP cameras and mobile cameras are excellent for their intended uses, they are unsuitable for defect detection and machine vision solutions in industrial applications. Their limitations in resolution, pixel size, image clarity, and motion handling make them ineffective for ensuring the precision and reliability required in quality control.

Machine vision cameras, on the other hand, are purpose-built for industrial environments, offering high resolution, optimized FPS, monochrome imaging, and line-scan capabilities. These features make them indispensable for detecting even the smallest defects on moving lines or reflective materials.

Intelgic specializes in designing and implementing machine vision systems tailored to your inspection needs. By leveraging the superior capabilities of machine vision cameras and advanced AI algorithms, Intelgic ensures that your quality control processes are efficient, accurate, and future-ready.

Contact us today to learn more about how Intelgic can enhance your defect detection and machine vision solutions.