Defect size on metal sheet surfaces that you should consider for inspection automation process.

Published on: Mar 03, 2025

Written by: Soumen das

Introduction

Metal sheets are widely used in automobiles, aerospace, construction, and various other industries, where surface quality is a critical factor in determining the usability of the material. Metal processing companies receive large sheets and perform operations such as slitting process, cut-to-length processing, and surface finishing before delivering them to customers.

Industries like automotive and aerospace are highly stringent when it comes to defect acceptance. Even minor defects such as scratches, pinholes, dents, and cutting defects can lead to product rejections, production delays, and financial losses.

To meet these strict quality standards, machine vision AI-powered Automated Optical Inspection (AOI) systems play a crucial role in automating defect detection, classification, and reporting.

Why Defect Size Matters in Metal Sheet Surfaces?

In industries like automotive and aerospace, even tiny surface defects can compromise structural integrity, safety, and performance.

Key Reasons Why Defect Size is Critical:

✔ Quality Standards Compliance: Defects larger than the acceptable threshold can cause rejections from customers.

✔ Structural Integrity & Performance: Scratches and dents may weaken metal sheets in applications like aircraft fuselage and automotive body panels.

✔ Manufacturing Efficiency: Undetected defects lead to waste, rework, and increased costs.

✔ Aesthetic Appeal: In industries such as appliances and consumer electronics, visible surface defects impact the final product's appearance and marketability.

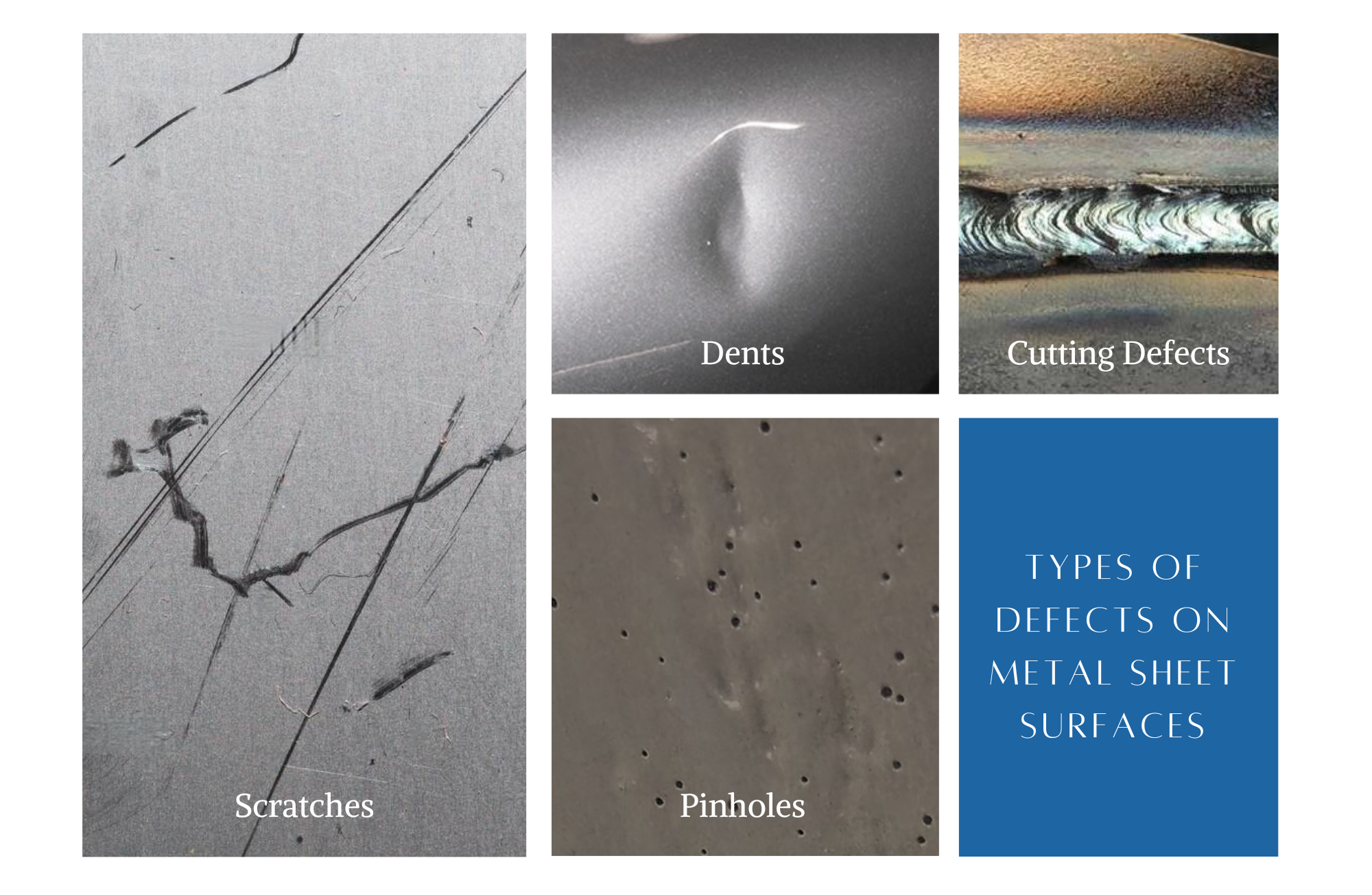

Types of Defects on Metal Sheet Surfaces

|

Defect Type |

Description |

Common Occurrence |

|

Scratches |

Surface abrasions caused by handling, cutting, or rolling. |

Found in automobile panels, aircraft skins, and coated metal sheets. |

|

Pinholes |

Small holes caused by contamination or processing errors. |

Common in aluminum foils, steel sheets, and coated surfaces. |

|

Dents |

Indentations caused by impact, pressure, or improper handling. |

Found in automotive body panels, aircraft fuselage, and industrial metal sheets. |

|

Cutting Defects |

Irregular or rough edges after slitting or cutting. |

Found in cut-to-length metal sheets, coil slitting, and edge trimming operations. |

Defect Size and Its Impact on Quality

The size of the defect plays a key role in determining acceptability and severity.

✔ Standard Defect Size Ranges in Metal Processing:

- Small Defects (0.25 mm - 0.5 mm):

- Minor surface imperfections that may be acceptable based on customer requirements.

- Medium Defects (0.5 mm - 1.5 mm):

- May require rework or surface finishing before delivery.

- Large Defects (Above 1.5 mm):

- Usually unacceptable in industries like automotive and aerospace.

💡 Intelgic’s Machine Vision AOI System is capable of detecting defects ranging from 0.20 mm to 2 mm, ensuring precise quality control in high-speed production environments.

Customizing Defect Acceptance Criteria Using AI

Each customer or industry may have different defect acceptance thresholds. For example:

✔ Automobile Industry:

- Acceptable scratch/pinholes size: < ~0.5 mm

- Unacceptable dent: > ~1 mm

✔ Aerospace Industry:

- Acceptable pinholes: < ~0.25 mm

- Unacceptable surface deviations: > ~ 0.5 mm

AI-Driven Adaptive Defect Detection

📌 Custom AI Training: Intelgic’s AI-driven inspection system allows manufacturers to train the AI model based on their customer's specific acceptance criteria.

📌 Defect Severity Classification: The system categorizes defects based on size and flags sheets that exceed the defect threshold.

📌 Automated Reporting: Generates reports with defect distribution, severity level, and suggested corrective actions.

How Intelgic’s Machine Vision AOI System Works

1. Dual-Sided Camera Installation for Complete Surface Inspection

- Cameras are installed on both the top and bottom of the sheet to inspect both surfaces simultaneously.

- Multi-angle imaging ensures no defects are missed.

2. High-Speed Line Scan Cameras for Continuous Monitoring

- Line scan cameras capture images line by line as the metal sheet moves on the conveyor.

- Ensures seamless detection of micron-level defects even at high speeds.

3. AI-Powered Defect Analysis

- Deep learning algorithms analyze each captured frame in real-time.

- The AI categorizes defect type, size, location, and severity.

4. Defect Severity Mapping & Reporting

- Severity level calculation: If a metal sheet contains multiple unacceptable defects within a defined length (e.g., 4 meters), the system can classify it as “rework” or “reject.”

- Live reports and alerts enable immediate action on defective sheets.

5. Integration with Manufacturing Execution Systems (MES)

- The AOI system automatically logs inspection data, making it easy to track defect trends and improve processes.

Benefits of Intelgic’s AI-Powered Defect Detection for Metal Sheet Inspection

Detects Defects from 0.20 mm to 2 mm with High Accuracy

Customizable AI Model Based on Customer Acceptance Criteria

Dual-Side Inspection Ensures Complete Coverage of Metal Surfaces

Real-Time Defect Classification and Reporting

Prevents Quality Rejections from High-Requirement Industries

Detecting and classifying defects on metal sheet surfaces is essential for maintaining high-quality standards in automotive, aerospace, and construction industries. Defects such as scratches, pinholes, dents, and cutting defects can vary in size and severity, impacting the final product's durability and performance.

Intelgic’s AI-powered Machine Vision AOI system provides a precise, automated solution to detect micron-level defects, classify them based on size and severity, and generate real-time reports to help manufacturers meet strict quality standards.

Contact Intelgic today to implement an AI-driven metal sheet inspection solution that ensures zero-defect manufacturing and optimized quality control!