What is Machine vision

Published Jun 11, 2024

Machine vision is essentially giving machines the ability to see. It uses cameras and other visual sensors to capture images, and then analyzes and interprets this visual data using powerful computer software. This allows machines to understand what they're "seeing" and take actions based on that information.

Imagine a world where machines or computers can not only perform tasks but also understand their surroundings. This is the promise of machine vision, a technology that equips machines with the power to see and analyze the visual world

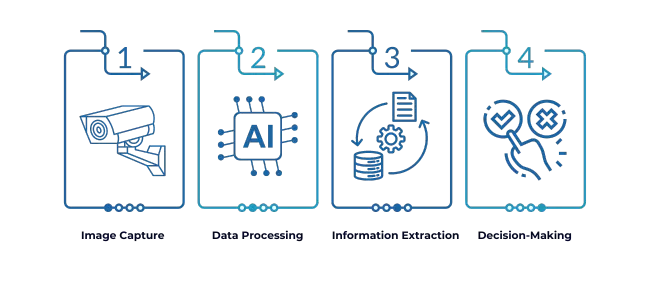

How machine vision works?

At its core, machine vision utilizes cameras and other visual sensors to capture images. But that's just the first step. The real magic lies in the software – complex algorithms powered by artificial intelligence (AI) and machine learning (ML) that take center stage. By processing and interpreting the captured visual data, these algorithms enable machines to extract meaningful information and make decisions based on what they "see."

The hardware behind machine vision is often familiar – cameras are the workhorses, but depending on the application, other sensors like LiDAR might also be employed. The software, however, is where the innovation lies. Here, AI and ML algorithms are trained on vast amounts of image data. This training allows them to identify patterns, classify objects, and even detect anomalies.

Machine Vision Use Case

The applications of machine vision are vast and ever-expanding. In the realm of industry, it has become a cornerstone of automation. Imagine a production line where machine vision systems meticulously inspect products, ensuring quality control by detecting even the slightest defect. Robots equipped with machine vision can perform intricate assembly tasks or navigate warehouses with precision, picking and placing objects with accuracy.

Beyond factories, machine vision plays a crucial role in our daily lives. Traffic monitoring systems leverage this technology to analyze traffic flow, identify accidents, and optimize traffic light patterns. In the medical field, machine vision assists doctors in analyzing X-rays and other medical scans, aiding in early diagnoses and treatment planning.

The potential of machine vision extends far beyond these examples. Security systems can utilize facial recognition to identify individuals, while self-driving cars rely on machine vision to navigate the roads, perceiving and reacting to their surroundings.

Machine Vision in manufacturing

Enhanced Quality Control:

- Visual Inspection: Human inspectors can miss subtle defects, but machine vision systems excel at spotting them. High-resolution cameras capture intricate details, while AI algorithms analyze them for inconsistencies in size, shape, color, or surface defects. This ensures only flawless products reach the market.

- Consistent Standards: Maintaining consistent product quality across large batches can be challenging. Machine vision enforces strict quality standards by automatically identifying and flagging defective items, ensuring uniformity throughout production.

Product counting:

- Product and object Counting: Machine vision excels at counting objects, products, components, parts, packages, whether they're finished products rolling off the line or individual components within a sub-assembly. This ensures accurate inventory control and prevents production delays due to missing parts. pen_spark

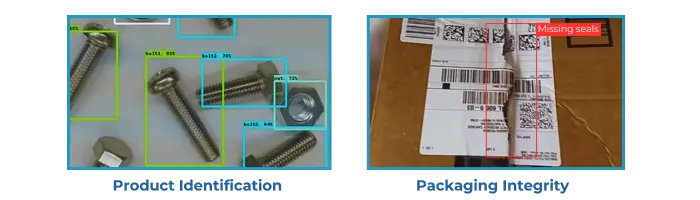

Product Identification Made Easy:

- Product Identification: Machine vision systems can identify specific products and also read texts on any of these products using techniques like OCR or barcode or QR code reading. This allows for tracking products through the production line and ensures correct packaging and labeling.

Packaging Integrity:

- Packaging Inspection: Properly sealed and undamaged packaging is essential for protecting products during transport. Machine vision systems can identify missing seals, tears, or dents, guaranteeing product integrity.

Despatch Area Monitoring:

- Enhanced Security: Machine vision can be used to monitor despatch areas, ensuring only authorized personnel access specific zones. Additionally, it can track outgoing shipments, verifying product quantities and preventing discrepancies.

Boosted Efficiency and Productivity:

- Automation on Steroids: Automated systems can handle high-volume production lines, inspecting products at lightning speed, freeing up human workers for more complex tasks. This translates to increased production throughput.

- Reduced Downtime: Machine vision systems can detect potential equipment malfunctions before they cause breakdowns. By identifying wear and tear on parts, predictive maintenance becomes possible, minimizing downtime and ensuring smooth operation.

Improved Safety and Cost Savings:

- A Safer Workplace: Machine vision can be used to monitor hazardous areas, ensuring worker safety. For instance, it can detect if a worker enters a restricted zone or isn't wearing proper safety gear, prompting corrective actions.

- Cost-Effectiveness: By minimizing defects, improving quality control, and reducing waste, machine vision systems lead to significant cost savings. Additionally, the efficiency gains from faster inspections and reduced downtime translate to a healthier bottom line.

Traditional Machine Vision Systems and AI-Driven Machine Vision Systems comparison

AI-driven machine vision systems represent a significant advancement over traditional systems, offering enhanced flexibility, scalability, and intelligence. These systems are more cost-effective and capable of adapting to complex, evolving industrial environments, making them invaluable in modern manufacturing and other industries.

| Feature | Traditional Machine Vision Systems | AI-Driven Machine Vision Systems |

|---|---|---|

| Technology Basis | Relies on fixed algorithms and predefined rules | Utilizes deep learning and AI algorithms that learn from data |

| Flexibility and Adaptability | Limited flexibility; needs reprogramming for new tasks | Highly adaptable; can learn and adjust to new tasks automatically |

| Scalability | Challenging to scale; each expansion requires new hardware and setup | Easily scalable; additional capacity often involves software updates or more data |

| Setup Complexity | Requires complex setups including specialized cameras and lighting | Simplified setup; often requires only standard cameras and software adjustments |

| Cost | High initial investment and maintenance costs | Lower cost over time; initial costs can be lower with |

| Cost | High initial investment and maintenance costs | Lower cost over time; initial costs can be lower with pay-as-you-go cloud resources |

| Maintenance | Requires frequent manual intervention and updates | Lower maintenance; can update and improve autonomously based on new data |

| Speed of Deployment | Slow deployment due to extensive setup and customization | Faster deployment with pre-trained models and cloud-based solutions |

| Processing Power | Relies on dedicated on-premises hardware | Leverages cloud-based GPU and edge computing for high performance |

| Accuracy and Precision | Fixed accuracy based on predefined criteria | Improved accuracy; continually learns and improves with more data |

| Error Handling | Rigid error detection and correction based on predefined rules | Dynamic error handling; can adapt to unexpected conditions through learning |

| Integration with Other Systems | Often requires custom integration solutions | Easier integration with other digital and IoT systems through modern APIs |

| Real-Time Capabilities | Limited real-time processing abilities | Advanced real-time processing enabled by AI and edge computing |

| Applications | Primarily suited for repetitive and well-defined tasks | Suitable for complex, variable tasks requiring pattern recognition and decision-making |

| Human Interaction | More dependent on human oversight for setup and adjustments | Less human interaction needed; can operate autonomously after initial training |

| Learning and Improvement | No learning capability; static performance over time | Continuous learning and improvement from new data inputs |