Understanding Controlled Environments in Machine Vision

Published Jun 19, 2024

In modern manufacturing, ensuring the highest quality of products is crucial. One of the key technologies enabling this precision is machine vision inspection. However, for machine vision systems to function at their best, they often require a controlled environment. This environment, where various factors such as lighting, shadow management, camera angle and cleanliness are meticulously regulated, is essential to maximize the accuracy and efficiency of these systems.

What is a Controlled Environment?

A controlled environment for a machine vision system in manufacturing refers to a setting where environmental conditions are carefully monitored and maintained to ensure consistent and optimal accuracy in defect detection and object counting. This includes regulation of lighting, camera angle, shadow management, and cleanliness. Controlled environments are particularly important in microscopic defect detection and small object counting using machine vision systems. Microscopic defect detection in electronics circuits, plastic products, coating products sometimes become challenging if the lighting conditions, camera angles are not proper. For the highest level of accuracy in defect detection, a controlled environment is one of the prerequisites. Similarly, lighting conditions, shadow management and camera angles are equally important for accurately counting small vials in pharmaceuticals and other small object detection and counting in other industries.

Importance of Controlled Environments in Machine Vision Inspection

1. Accuracy:

A controlled environment ensures that the camera is sending clear images to the machine vision system. For accurate defect detection, machine vision needs images that have no shadows and reflections. For object counting, all the edges should be clearly visible and objects should be properly distinguishable.

2. Faster image processing:

Clear images do not need image preprocessing that leads to less computation and faster image analysis. If the images are blurred or have shadows, machine vision engineers may need to apply image processing techniques to improve image quality and that may need additional time for detecting defects.

3. Minimized Contamination:

In industries like electronics, plastic parts and coating contamination can lead to significant product defects. Controlled environments help maintain cleanliness, reducing the risk of particles or other contaminants interfering with the inspection process.

Role of Lighting Conditions and Shadows

Lighting conditions and shadow management are critical aspects of machine vision inspection within a controlled environment. Proper lighting ensures that features of interest are well-illuminated and visible to the camera, while effective shadow management prevents visual obstructions.

1. Optimal Lighting Conditions:

- Types of Lighting:

- Backlighting: Illuminates the object from behind, creating a silhouette that highlights edges and contours, useful for inspecting transparent or translucent materials such as white plastic products.

- Bright Field Lighting: Direct illumination on the object, highlighting surface features such as textures, colors, and defects.

- Dark Field Lighting: Side illumination, making surface imperfections like scratches or cracks more visible.

- Techniques:

- Diffuse Lighting: Uses diffusers to scatter light evenly, reducing glare and shadows, ideal for inspecting reflective surfaces.

- Structured Lighting: Projects a pattern of light (e.g., grids or stripes) onto the object, useful for 3D shape analysis and surface inspection.

2. Shadow Management:

- Challenges: Shadows can obscure critical features, leading to inaccurate inspections and false positives or negatives.

- Solutions: Proper lighting design can minimize shadows. Techniques such as using multiple light sources and adjusting the angle of illumination help reduce or eliminate shadows, ensuring that all relevant features are visible.

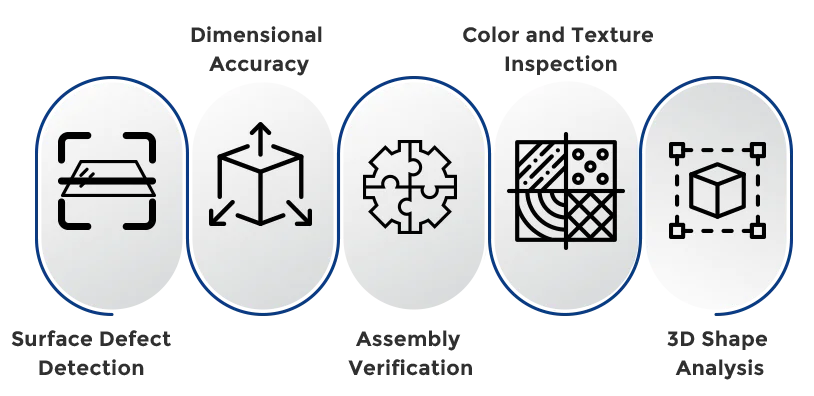

Applications of Controlled Environments in Machine Vision

1. Surface Defect Detection:

Proper lighting and controlled conditions highlight surface defects such as scratches, dents, and cracks, enabling accurate detection and classification.

2. Dimensional Accuracy:

Backlighting creates clear silhouettes for precise measurement of object dimensions, ensuring products meet exact specifications.

3. Assembly Verification:

Bright field lighting ensures that components are correctly assembled and positioned, highlighting features like part presence, orientation, and alignment.

4. Color and Texture Inspection:

Consistent lighting is crucial for inspecting color and texture variations, ensuring accurate color reproduction and visibility of textures.

5. 3D Shape Analysis:

Structured lighting projects patterns onto objects for detailed 3D shape analysis, useful for inspecting complex geometries and ensuring correct component fit.

Benefits of Controlled Environments for Machine Vision Inspection

1. High Accuracy and Precision:

Controlled environments eliminate variables that can affect inspection accuracy, ensuring precise and consistent results.

2. Increased Speed and Efficiency:

With optimal conditions, machine vision systems can operate at higher speeds without sacrificing accuracy, boosting overall production efficiency.

3. Reduced Defects and Waste:

Consistent inspection conditions lead to fewer defects going undetected, reducing rework and waste.

4. Enhanced Product Quality:

Reliable and precise inspections ensure that only high-quality products reach the market, improving customer satisfaction and brand reputation.

5. Regulatory Compliance:

Maintaining a controlled environment helps meet industry regulations and standards, especially in sectors like pharmaceuticals and electronics.

Controlled environments are essential for maximizing the effectiveness of machine vision inspection systems in manufacturing. By maintaining stable and optimal conditions, these environments enhance the accuracy, reliability, and efficiency of inspections. Proper lighting and shadow management are key components of a controlled environment, ensuring that critical features of products are clearly visible and accurately analyzed. As technology advances, the integration of sophisticated lighting solutions and environmental controls will further improve the capabilities of machine vision systems, driving innovation and excellence in manufacturing.