Vision AI Use Cases in Tyre Manufacturing: Transforming the Industry

Published February 10, 2024

The integration of Vision AI in tyre manufacturing marks a revolutionary shift in how the industry approaches quality control, visual inspection, safety, and efficiency. This technological advancement brings several use cases to the forefront, revolutionizing the traditional methodologies of tyre production.

Defect Detection and Visual Inspection automation for Quality Analysis

One of the primary applications of Vision AI in tyre manufacturing is in defect detection and quality analysis. Tyres, being complex structures made of various materials like rubber, steel, and textiles, are prone to hidden material defects due to production errors or incorrect management systems. Vision AI systems, utilizing Convolutional Neural Networks (CNNs), can analyze images or videos from the production line to identify these defects, which include sidewall cracks, rim line cracks, sidewall blisters, and other anomalies that could affect the tyre's performance and safety. This early and accurate defect detection helps manufacturers optimize production, reduce waste, and ensure the high quality and safety of their products.

Automated alerts can be set up to intervene before defective products, malfunctioning equipment, or foreign objects slow or stall production, ensuring consistent quality and safety standards.

Assembly Line Inspection

Vision AI plays a crucial role in inspecting the assembly lines, ensuring that each tyre component is assembled correctly. These systems can identify incorrect placements, missing parts, or assembly errors that could lead to product failure. Through high-resolution cameras and machine learning algorithms, Vision AI offers a more efficient and precise method of conducting visual inspections compared to traditional manual methods.

Product counting, Object detection and Supply Chain Optimization

Vision AI can accurately count products, raw materials, parts and other objects automatically and send reports to ERP for further analysis. By analyzing real-time video data, the AI systems can monitor inventory levels, detect empty containers for replenishment, and ensure the accurate tracking of products through the supply chain. This real-time processing capability allows for more efficient warehouse management, inventory control, and overall productivity enhancement.

Foreign object detection in tyre manufacturing

Foreign objects in tyres can range from metal fragments, stones, or other materials that inadvertently become embedded in the tyre during production. These objects can compromise the structural integrity of the tyre, leading to potential safety issues such as tyre failure, blowouts, or reduced lifespan. Therefore, detecting and removing these foreign objects early in the manufacturing process is critical.

Reduced Downtime and Waste: By automating the detection process, manufacturers can reduce production downtime and minimize waste. This not only improves efficiency but also contributes to cost savings and higher product quality.

Label inspection, reading and information validation

Tyre labels contain critical information such as numbers, size, type, performance ratings (including fuel efficiency, wet grip, and noise levels), and compliance marks. Vision AI systems use high-resolution cameras to capture detailed images of the tyre labels. Through machine learning algorithms, these systems can detect even the slightest inaccuracies in text or symbols, ensuring that all printed information is correct and legible.

Vision AI systems can instantly validate label information against pre-set standards and databases. This real-time capability ensures that any errors are identified and corrected immediately, preventing faulty products from progressing further in the production line.

Predictive Maintenance

Predictive maintenance is another area where Vision AI has significant impact. By monitoring machinery and equipment, these systems can detect early signs of wear and tear, corrosion, or other issues that could lead to downtime or accidents. This proactive approach to maintenance ensures continuous production and extends the lifespan of manufacturing equipment.

Heating, flames, smoke, fire detection

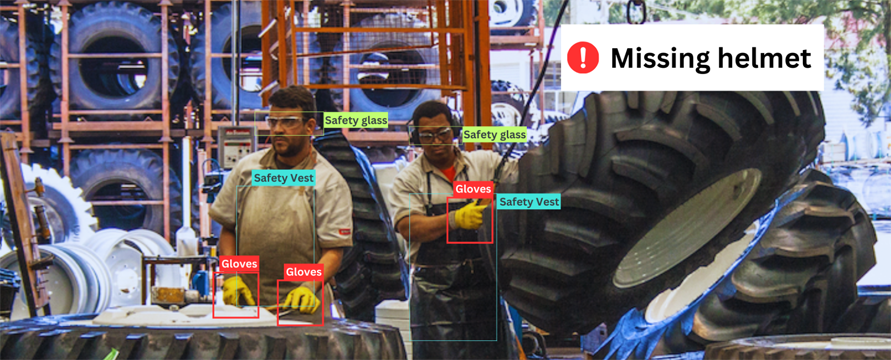

Safety Standards and Worker Protection

Ensuring the safety of workers in tyre manufacturing plants is paramount. Vision AI systems can monitor work areas for compliance with safety standards, detect unsafe behaviors or conditions, and alert management to potential hazards. This not only helps in preventing accidents but also contributes to creating a safer working environment.

The integration of Vision AI into tyre manufacturing represents a significant advancement in the industry's ability to produce high-quality, safe products efficiently. From defect detection and assembly line inspection to supply chain optimization and predictive maintenance, Vision AI is transforming the tyre manufacturing process. As manufacturers continue to embrace these technologies, we can expect further innovations and improvements in the production of tyres, ultimately benefiting both the industry and consumers

Vision AI's role in tyre manufacturing is just the beginning of its potential impact on the broader manufacturing sector. By harnessing the power of AI and machine learning, the industry is setting new standards for quality, efficiency, and safety, marking a new era in manufacturing excellence