Intelgic's AI-Powered Automated Optical Inspection (AOI) System for Inspection Automation in Manufacturing

In today’s fast-paced manufacturing environment, maintaining product quality and defect-free production is critical. Intelgic’s AI-powered Automated Optical Inspection (AOI) system provides a complete inspection automation solution for manufacturers across industries, ensuring precise defect detection, anomaly identification, SOP monitoring, object detection, and counting.

With Intelgic’s AOI system, manufacturers can increase production accuracy, minimize waste, and improve efficiency, whether on a high-speed production line or in stationary inspection booths.

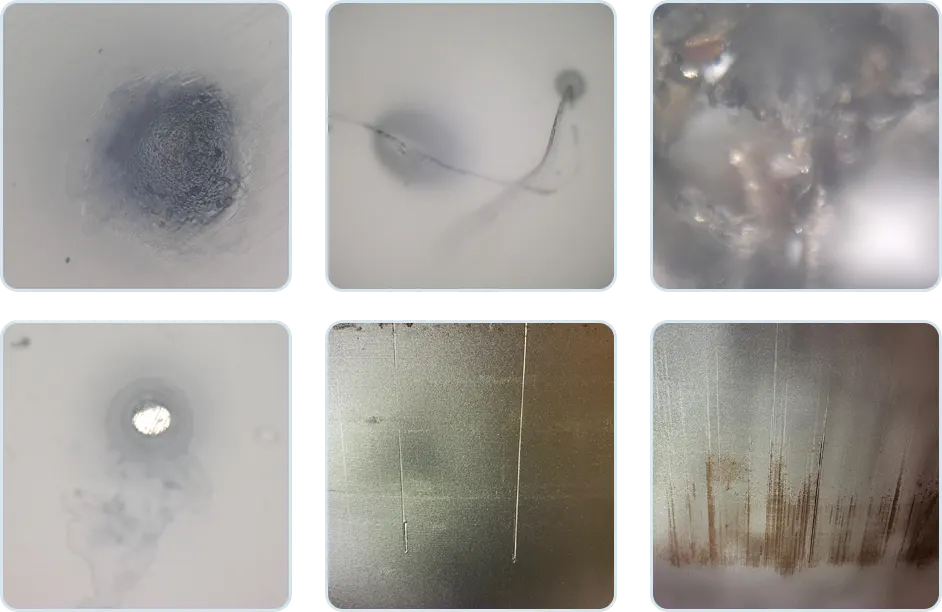

Intelgic’s AOI system is capable of detecting a wide range of defects across different surfaces and materials, ensuring thorough quality control and precise defect classification.

Scratches, Pits, Pin Holes, Splits, Minor Deviations, Color Defects, Dents, Bumps – Our AI system is Pre-trained with millions of images, which makes it highly accurate and capable of detecting even the most complex anomalies in various products and surfaces.

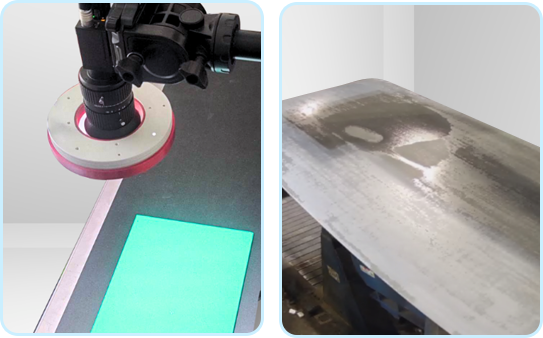

Our AI-powered system can detect defects of all sizes, starting from 5 microns to 100 mm or more. Depending on the defect size, product material, line speed, and environmental conditions, we select the optimal imaging sensor, camera, lenses, and lighting setup to maximize detection accuracy.

Our AI-powered AOI system is designed to work seamlessly in high-speed manufacturing lines, detecting defects automatically as products move on conveyor systems. This real-time inspection ensures that manufacturers maintain quality standards and avoid costly defects before products reach the next stage.

For large, complex, or stationary products, Intelgic’s AOI system ensures detailed anomaly detection in inspection booths. This application is ideal for large and intricate components such as automobile parts that require precise defect analysis. Stationary inspection is also ideal for very small parts inspection.

Intelgic’s Live Vision AI extends beyond defect detection to provide process control and production monitoring with AI-based:

Intelgic’s AI-powered AOI system provides manufacturers with a powerful, scalable, and highly accurate inspection automation solution. Whether you need real-time defect detection on high-speed production lines or detailed anomaly detection in inspection booths, our cutting-edge machine vision technology ensures the highest level of quality control.

Let Intelgic’s AI-driven Automated Optical Inspection (AOI) System transform your manufacturing quality control and ensure defect-free production!

©2025 Intelgic Inc. All Rights Reserved.