Factory AI: A complete guide before you start implementing AI in your factory

Published March 22, 2024

Factories are complex ecosystems of machinery, equipment, and raw materials within a complex operational environment. Traditionally, automation of manufacturing processes within such settings has led to the procurement and implementation of large, costly machinery, challenging to integrate into the existing factory setup. But recently the rise of Artificial Intelligence (AI) has unlocked new avenues in factory automation. These new evolved AI technologies allow for a shift towards software-centric automation systems from the machine dependent system. The AI is capable of transforming and automating manufacturing processes without relying on the acquisition of heavy machinery. This article will tell you what is the Factory AI and what do you need to know before you start an AI project within your factory

What is Factory AI

Factory AI uses deep learning AI algorithms along with cameras and sometimes other sensors to automate and streamline manufacturing processes without involving heavy machinery.

Setup a camera in any strategic location and connect it to an AI server within your facility or to a cloud to analyze the video stream and get many insights that you never had before. AI algorithms, along with a camera can automate many processes such as product counting, tracking, identifying, monitoring and inspecting are some of the processes.

Why factory AI is different from the generic AI

Most of the time the generic AI models that are trained with open sourced, internet data do not work in the factory automation. Factories have their own unique environment, machines, products and these datasets generally are not available on the internet. To get desired results, factories need to train AI models with their own dataset.

Moreover, Factory AI applications are designed to address specific problems instead of general issues across the industry. Depending on the industry, many regulations and guidance are to be followed while designing the solution. For example, the pharmaceutical industry is highly regulated by FDA, and regulations like part 11 have to be followed while providing an AI application for them.

Vision AI for factory automation

Vision AI has transformed factory automation in recent years. AI algorithms along with machine vision cameras have the ability to transform many processes.

Product defect detection

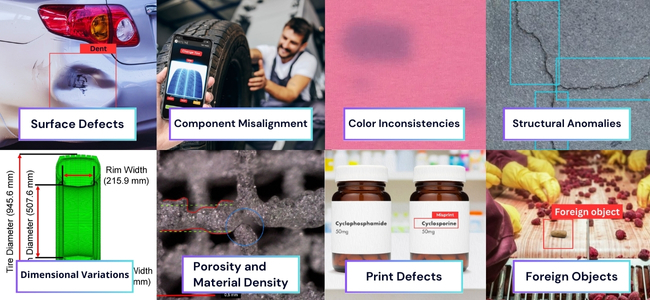

Vision AI can detect a wide array of defects across various industries, enhancing product quality and consistency. Some defects that Vision AI systems are adept at identifying include:

Surface Defects: Scratches, dents, cracks, and stains on products can be detected with high accuracy, applicable in automotive manufacturing, electronics, and metal fabrication.

Dimensional Variations: Deviations from specified dimensions, such as length, width, height, or diameter, are identified, crucial for precision engineering and manufacturing sectors.

Component Misalignment: Improper alignment of parts, such as in assembly lines for electronics or automotive parts, where precision is paramount.

Color Inconsistencies: Variations in color or patterns not meeting the set standards, significant in textile, paint, and plastics industries.

Structural Anomalies: Flaws in the structure, such as in welded joints or cast metal parts, critical in construction materials and machinery manufacturing.

Foreign Objects or Contamination: Detection of unwanted materials or particles in products, especially in food processing and pharmaceutical manufacturing.

Print Defects: Errors in labeling, packaging, or any printed materials, such as smudges, misprints, or incorrect information, vital for consumer goods.

Porosity and Material Density: Identifying pores or variations in material density that could affect product integrity, applicable in industries like aerospace and dental equipment manufacturing. By leveraging Vision AI, companies can ensure their products meet the highest quality standards, reducing the risk of recalls and enhancing customer trust.

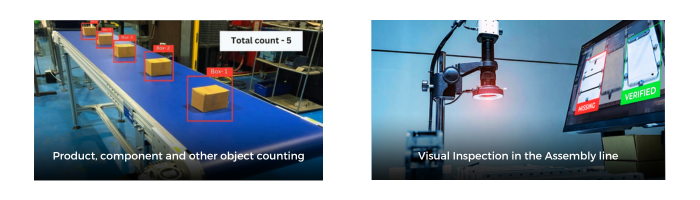

Product, component and other object counting

Vision AI revolutionizes the task of counting products, components, and other objects with unparalleled accuracy and speed, surpassing traditional manual counting methods or sensor-based systems. By analyzing images or video streams, Vision AI algorithms can quickly identify and tally items, regardless of their size, complexity or arrangement.

Furthermore, Vision AI supports quality control by ensuring the correct number of components are present in assemblies, reducing the risk of errors in packaging or assembly lines. Its adaptability allows for deployment across various sectors, including automotive, electronics, pharmaceuticals, and agriculture, enhancing efficiency and reducing the potential for human error in counting tasks.

Visual Inspection in the Assembly line

Visual inspection in assembly lines, utilizing Vision AI, plays a crucial role in ensuring that the correct products are packaged and shipped. This technology streamlines the verification process by matching products against purchase orders to confirm that the right items and quantities are being dispatched. Vision AI systems analyze video streams of products on the assembly line in real-time, identifying and tallying them with remarkable accuracy.

This not only facilitates the fulfillment of specific customer orders but also significantly reduces the risk of shipping errors that leads to return of products and reshipping. Manual errors in shipment and reshipping, costs tens of thousands of dollars for many manufacturing companies. Use Vision to ensure only the ordered products make their way to customers.

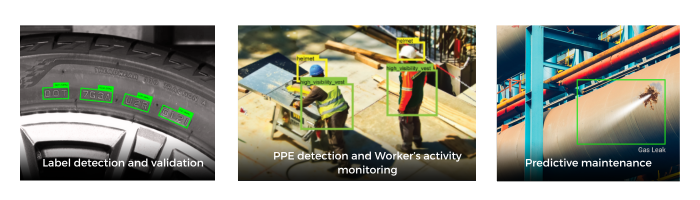

Label detection and validation

By employing sophisticated AI algorithms, Vision AI systems can automatically detect and validate labels on products, verifying information such as product names, expiration dates, barcodes, and regulatory compliance marks. This process not only streamlines packaging operations but also significantly reduces the risk of human error, ensuring that products are correctly labeled before they reach consumers

PPE detection and Worker’s activity monitoring

The AI technology allows for the real-time analysis of video feeds to ensure that workers adhere to Personal Protective Equipment (PPE) requirements, such as helmets, safety glasses, and gloves, crucial for preventing injuries in hazardous environments. Beyond safety gear compliance, Vision AI can also monitor worker activities, identifying inefficiencies, and ensuring adherence to protocols, thereby optimizing workflows and productivity. By automating these surveillance tasks, companies can not only ensure a safer workplace but also leverage data-driven insights to improve processes and reduce operational bottlenecks.

Predictive maintenance

Vision AI systems can continuously monitor equipment and machinery, detecting subtle changes that may indicate impending failures or wear. This real-time surveillance enables the early identification of issues such as cracks, corrosion, or misalignments before they escalate into costly breakdowns. Unlike traditional maintenance approaches that rely on scheduled inspections or respond to failures after they occur, Vision AI-driven predictive maintenance anticipates problems, allowing for timely interventions.

What do you need to know before you start an Factory AI project

Identify the the Problem that you want to solve

The first step in any successful Factory AI project is to clearly identify the problem you aim to solve. Industrial Vision AI, for example, has the capability to analyze video and images, often surpassing human capabilities in tasks such as object detection, counting, and incident detection. By examining your processes closely, you can pinpoint areas where AI can bring significant improvements, insights and ROI.

Custom AI Training with Your Dataset

A unique aspect of Factory AI projects is the need for custom-trained AI models. Unlike general AI applications, industrial settings require bespoke solutions tailored to specific operational challenges and environments. This often involves training models on proprietary datasets not available in the public domain. The accuracy and effectiveness of your AI solution will hinge on this custom training, emphasizing the importance of a tailored dataset.

Gathering the Right Data

Before starting on your AI journey, it's crucial to collect and prepare the necessary dataset. This means capturing high-quality images or videos of your products or processes, including any defects or variations you wish to detect. The success of your AI model depends on the quality and comprehensiveness of this data.

Camera Installation and Location

Identifying strategic locations for camera installation is another critical step. Ensure that cameras are placed to capture a comprehensive view of the scene of interest. The resolution and capabilities of your cameras will directly impact the effectiveness of your AI system, making it essential to choose the right equipment and possibly consult with AI experts.

Do you need an On-Prem or a Cloud server

The choice between processing video streams on a cloud server or an on-premises server involves weighing the pros and cons of each option. Cloud processing offers scalability, low downtime, and ease of maintenance, but it may raise data security concerns and depends heavily on internet connectivity. On-premises processing provides enhanced data security and control, yet it may face scalability and complexity challenges. The server capacity and configuration depends on the size of the AI model. Talk to an Expert to know the server details.

Secured Cloud Processing:

Pros:

- Scalability: Cloud services can easily scale up or down based on demand, offering flexibility and efficiency.

- Low downtime: Secured cloud like Azure, AWS, GCP has low downtime. For sensitive process, you can use one of these cloud to run your industrial AI apps

- Maintenance: Cloud is easy to maintain. It can be maintained, monitor remotely. It also reduces the burden on internal IT teams.

Cons:

- Data Security Concerns: Transmitting sensitive information to the cloud can raise security concerns, though reputable providers offer robust security measures.

- Cost: To run a large AI application, you may need an expensive GPU server and per-month billing can pinch your pocket.

- Dependency on Internet Connectivity: Requires a stable and high speed internet connection, which can be a limiting factor in areas with poor connectivity.

- Latency: Depending on the cloud provider's location, there can be latency issues that affect real-time data processing needs.

On-premises Processing:

Pros:

- Data Security: Keeping the data processing on-site can enhance security, as sensitive information does not have to travel over the internet.

- Cost: If you have large AI models that need high capacity GPU servers, you can purchase them with a one-time initial cost. This will be cost effective in a log-run.

- Control: Businesses have full control over the hardware and software, allowing for customizations tailored to specific needs.

- Performance: Processing data locally can reduce latency, offering real-time analytics and faster response times for critical applications.

Cons:

- Scalability: Scaling up requires physical hardware additions, which can be slower and a burden on the internal IT team.

- Uptime: If anything goes wrong in the hardware level, it is difficult to make the system running within a short time.

- Complexity: Requires in-house expertise for setup, maintenance, and troubleshooting, which can add to operational complexities.

Expert Guidance

Seeking expert guidance can greatly increase the chances of your project's success. Consulting firms specializing in Industrial AI can offer valuable insights, from evaluating feasibility to implementing AI technologies effectively. Their expertise can help navigate the complexities of AI integration, ensuring that your Factory AI project not only meets but exceeds expectations.

Starting on a Factory AI project is a journey towards transforming your manufacturing processes. By carefully considering these aspects, you can harness the full potential of AI to enhance efficiency, improve quality, and drive innovation in your factory operations.