Defect Detection in Tyre Manufacturing: Leveraging Vision AI

Published February 25, 2024

Vision AI has transformed the way tyre manufacturing companies detect and classify defects in tyres. By leveraging deep learning and computer vision technologies, these systems can accurately identify a wide range of defects that may compromise the quality and safety of tyres. Here's an overview of common tyre defects and how vision AI can detect them:

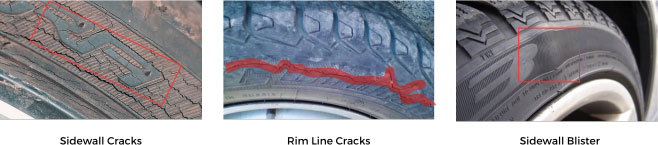

Sidewall Cracks (SWC)

Description: Cracks in the sidewall of the tyre often caused by exposure to environmental factors, poor material quality, or the manufacturing process.

Detection: Vision AI systems can detect these cracks by analyzing the texture and pattern differences on the tyre's sidewall. Machine learning models specifically trained on images with sidewall cracks can distinguish between normal sidewall textures and the irregular patterns caused by cracks.

Rim Line Cracks (RLC)

Description: Cracks around the tyre's rim area, potentially leading to air leaks and reduced tyre integrity.

Detection: Using high-resolution imaging, AI algorithms can pinpoint the fine lines indicative of rim line cracks. These systems can differentiate between the normal rim line and abnormalities, flagging areas that show deviation from standard patterns.

Sidewall Blister (SWB)

Description: Raised areas or bubbles on the sidewall, indicating separation of the internal layers of the tyre.

Detection: Vision AI leverages differences in shadow and contour to identify blisters on the sidewall. By examining the surface texture and elevation changes, the system can highlight areas where blisters are forming.

Stencil Number Offset

Description: or incorrect placement of the stencil numbers used for tyre identification and tracking.

Detection: AI systems are trained to recognize the standard positioning and alignment of stencil numbers. Any deviation from the norm, such as misalignment or blurring of numbers, can be detected through pattern recognition techniques.

Chamfer Defect

Description: in the chamfer, the angle or bevel cut on the tyre, which can affect tyre fitting and performance.

Detection: analyzing the geometric shapes and edges on the tyre, vision AI systems can identify inconsistencies in the chamfer's angle or symmetry, indicating a defect.

How Vision AI Detects These Defects:

Vision AI systems use a combination of techniques including image segmentation, pattern recognition, and machine learning algorithms to detect tyre defects. These systems are trained on image datasets containing images of tyres with various defects, allowing them to learn and accurately identify defects in new images. Techniques such as convolutional neural networks (CNNs) are pivotal in analyzing visual imagery, enabling the AI to distinguish between normal tyre conditions and abnormalities effectively.

The process typically involves capturing high-resolution images or videos of tyres from multiple angles using cameras or laser sensors. The captured visual data is then processed and analyzed by the AI system, which applies trained models to detect and classify the defects. The use of unsupervised learning methods such as clustering can also assist in identifying new or untrained abnormalities by analyzing patterns and deviations from the norm.

In practice, vision AI systems enhance the accuracy and efficiency of tyre inspection processes, reducing the reliance on manual inspections and improving overall product quality and safety.