Challenges in Metal Sheet Inspection and precised AOI solution

Published on: Feb 12, 2025

Written by: Content team, Intelgic

Challenges in Metal Sheet Inspection and how AOI solves them

Metal sheet inspection is a critical process in the manufacturing industry, ensuring product quality, durability, and compliance with stringent industry standards. However, traditional inspection methods are often fraught with challenges, ranging from manual inefficiencies to inconsistent quality assessment. With the advent of AI-powered machine vision, the landscape of metal sheet inspection is undergoing a transformation. This article delves into the challenges associated with metal sheet inspection, the common defects encountered, and how AI-powered solutions, including advanced imaging, illumination, and software technologies, address these challenges.

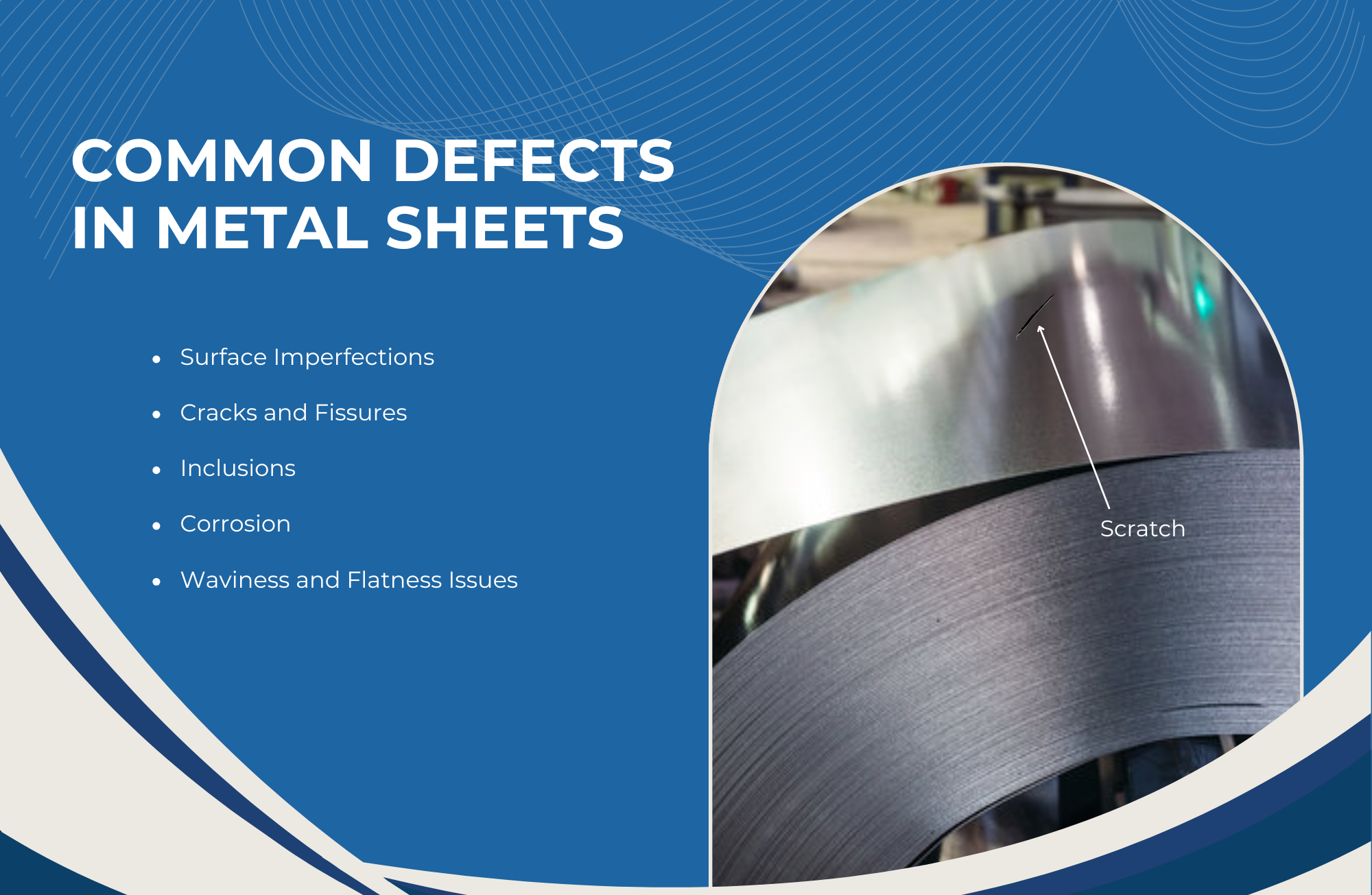

Common Defects in Metal Sheets

Metal sheets are prone to a variety of defects that can occur during manufacturing, handling, or storage. Some of the most common defects include:

- Surface Imperfections: These include scratches, pits, and dents that can occur during rolling, cutting, or transportation. Surface imperfections can affect the aesthetic appeal and functionality of the metal sheet.

- Cracks and Fissures: These are often caused by stress during manufacturing or thermal expansion and contraction. Cracks can significantly weaken the metal sheet, leading to potential failures in application.

- Inclusions: Non-metallic impurities embedded within the metal sheet can compromise its structural integrity. Inclusions are often introduced during the melting and casting processes.

- Corrosion: Exposure to moisture and corrosive environments can lead to rust and other forms of corrosion, which can degrade the metal over time.

- Waviness and Flatness Issues: These defects occur when the metal sheet does not have a uniform thickness or flatness, affecting its suitability for specific applications.

Challenges in Metal Sheet Inspection

Detection of Minute Defects : Metal sheets often exhibit microscopic surface and subsurface defects, such as cracks, pits, or inclusions, which are difficult to detect with conventional inspection methods.These defects, though small, can compromise the structural integrity and performance of the metal, making their identification crucial.

Variability in Material Properties : Different metals and alloys have unique characteristics, such as reflectivity, texture, and thermal conductivity, which can affect inspection accuracy.A single inspection system may not be suitable for all types of metals, necessitating adaptable and customizable solutions.

Wide Metal Sheets (1000 mm – 1600 mm) : In most cases, the width of metal sheets ranges from 1000 mm to as much as 2000 mm or more, making it challenging for a single camera to capture the entire width in a single frame. This limitation necessitates the use of multiple cameras or advanced imaging setups to ensure comprehensive coverage and accurate inspection across the entire sheet

High-Speed Production Lines: Manual inspection cannot keep pace with modern high-speed production lines, leading to potential defects being overlooked.

Surface Reflectivity and Glare : Metal surfaces are highly reflective, causing glare and shadows that can obscure defects during visual or camera-based inspections.

Flatness and Thickness Variations : Detecting waviness, warping, or uneven thickness across large sheets is challenging, especially in high-volume production settings.

Manual Inspection Limitations : Human inspectors are prone to fatigue, inconsistency, and oversight, especially when dealing with repetitive tasks or large volume.

Environmental Factors: External conditions such as temperature fluctuations, humidity, and dust can interfere with inspection equipment and affect results.

Cost of Rework and Scrap: Undetected defects can lead to costly rework, material waste, and reputational damage due to defective products reaching customers.

How Automated Optical Inspection (AOI) Addresses These Challenges

To effectively overcome the challenges associated with metal sheet inspection, an Automated Optical Inspection (AOI) system is deployed. This sophisticated system integrates advanced machine vision cameras, precision lighting, synchronized controllers, and AI-driven software to enable real-time defect detection with unparalleled accuracy and efficiency.

Line Scan Cameras (For High-Speed and Wide Sheet Inspection):

These high-resolution cameras capture images line by line as metal sheets move along the conveyor, enabling seamless inspection at high speeds. They detect defects as small as 100 microns, ensuring precise quality control. To cover sheet widths of 1000 mm to 2000 mm or more, up to three cameras are strategically positioned, maintaining optimal image quality across the entire surface.

High-Resolution Image Sensors :

High-resolution sensors ensure defects span multiple pixels for enhanced detectability, making even subtle imperfections visible.

High-Intensity Specialized Lighting :

Uniform and high-intensity lighting is employed to illuminate the metal surface, ensuring that even microscopic defects are visible to the cameras.The lighting system is designed to eliminate shadows and reflections, which are particularly problematic on highly reflective metal surfaces.Advanced illumination systems, such as structured light and diffuse lighting, are designed to mitigate these issues.

Encoder (For Speed Synchronization) :

An integrated encoder provides real-time speed signals to prevent motion blur, ensuring clear images even at fluctuating conveyor speeds.

AI-Powered Defect Detection Software:

At the core of the AOI system is advanced AI-powered software that analyzes captured images in real-time to identify defects such as scratches, pits, pinholes, and corrosion.

The software is trained on extensive datasets, enabling it to classify defects with high accuracy and adapt to varying inspection requirements.

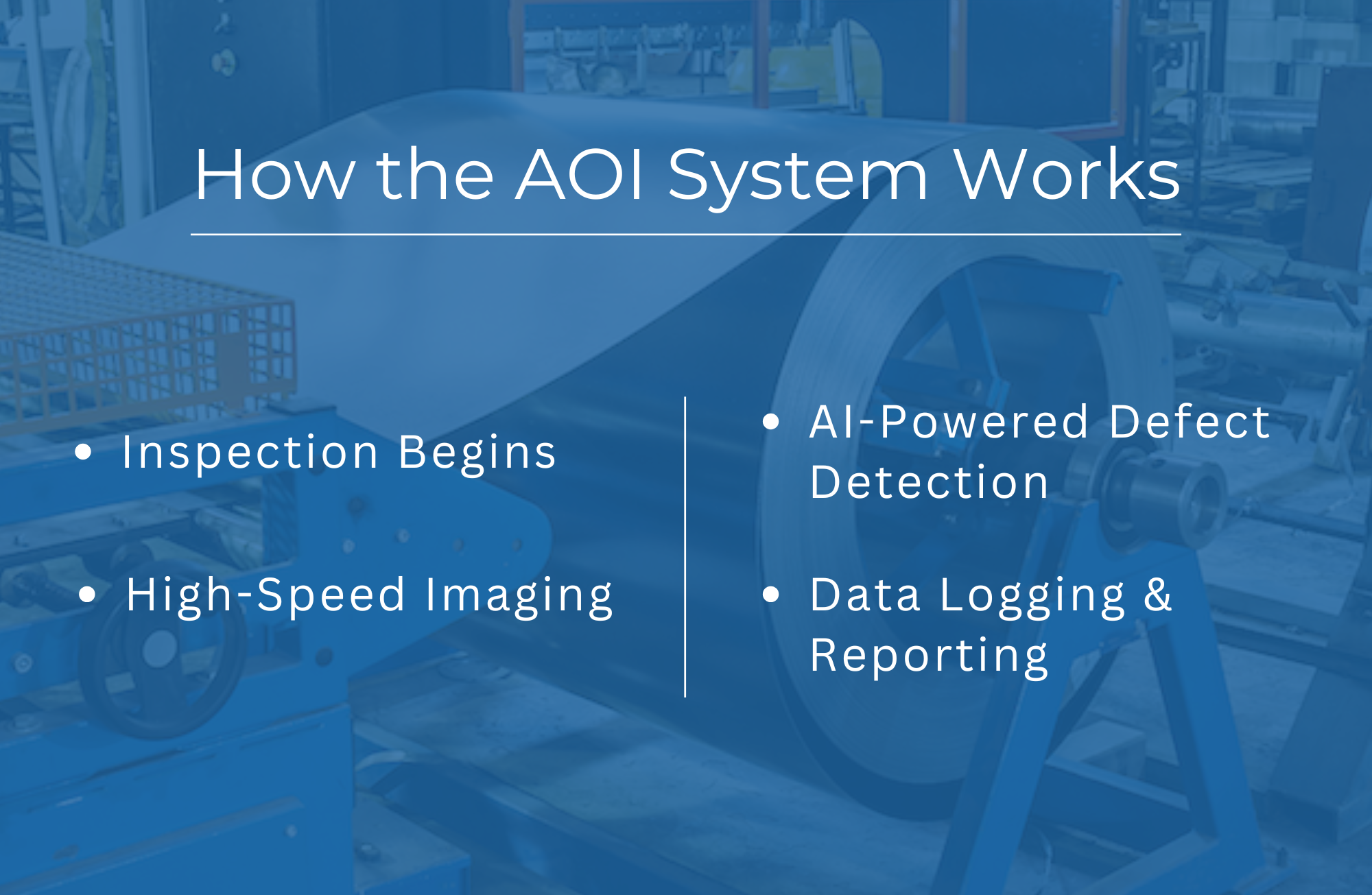

How the AOI System Works

- Inspection Begins

Metal sheets move onto the conveyor, where cameras and lighting systems are positioned for optimal scanning. - High-Speed Imaging

Line scan cameras capture continuous high-resolution images, ensuring full coverage of the sheet width. - AI-Powered Defect Detection

Advanced AI analyzes images in real time, identifying and classifying defects based on type, size, and severity. - Data Logging & Reporting

Defect images and data are stored with unique product IDs, ensuring traceability and detailed quality reports.

Benefits of AOI Implementation in Metal Sheet Inspection

- High-Speed & Continuous Inspection – Enables real-time defect detection without slowing down production.

- Enhanced Defect Detection – Identifies minute defects (as small as 100 microns) with high precision.

- Consistent & Reliable Quality Control – Eliminates human error and ensures uniform inspection standards.

- Full Sheet Coverage – Multiple cameras provide seamless inspection across wide metal sheets.

- AI-Powered Accuracy – Advanced AI algorithms classify defects based on type, size, and severity.

- Customizable Inspection Parameters – Adjusts defect detection criteria based on material and production needs.

- Real-Time Reporting & Alerts – Generates instant reports and alerts for quick corrective action.

- Cost Savings – Minimizes material waste, labor costs, and potential product recalls.

- Compliance & Documentation – Provides comprehensive inspection records for regulatory and customer requirements.

- Seamless Integration – Easily integrates with existing manufacturing and quality control systems.

Implementing AOI in metal sheet inspection enhances quality control, reduces defects, and optimizes production efficiency. With Intelgic’s advanced AI-driven AOI system, manufacturers benefit from high-speed, precision inspection, automated defect detection, and real-time reporting. Intelgic stands out with its cutting-edge AI algorithms, seamless integration, and adaptive inspection capabilities, ensuring unmatched accuracy and reliability in metal sheet quality assurance.

Contact Intelgic today to discover how our advanced AOI solutions can enhance your inspection process and improve quality control.