What is a Telecentric Lens

Published on: Jan 09, 2025

Written by: Content team, Intelgic

What is a Telecentric Lens?

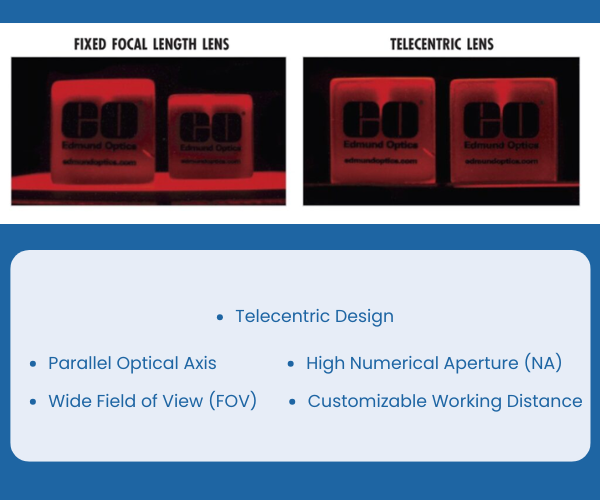

A telecentric lens is a type of optical lens designed to ensure consistent magnification, regardless of the distance between the lens and the object being inspected. Unlike traditional lenses, telecentric lenses eliminate perspective distortion, making them ideal for precision measurement and defect detection tasks in machine vision applications.

What Makes Telecentric Lenses Unique?

-

Consistent Magnification:

-

Telecentric lenses maintain uniform magnification across varying object depths.

-

Ensures that objects of different heights or at varying distances are imaged with consistent proportions.

-

-

Elimination of Perspective Distortion:

-

Traditional lenses introduce perspective distortion, making closer objects appear larger.

-

Telecentric lenses correct this, capturing objects with true-to-scale dimensions.

-

-

High Resolution and Low Distortion:

-

Designed for precision, telecentric lenses minimize optical distortion, ensuring accurate measurements and defect detection.

-

-

Large Depth of Field:

-

Provides sharp focus across objects with varying heights, essential for inspecting uneven surfaces.

-

When to Use Telecentric Lenses

Telecentric lenses are ideal for machine vision applications that demand precision, consistency, and accuracy. Here are some scenarios where they excel:

-

Dimensional Measurement:

-

Applications requiring precise gauging of dimensions, such as part widths, diameters, or distances.

-

Common in industries like electronics, automotive, and medical devices.

-

-

Defect Detection:

-

Inspection tasks where the size and position of defects need to be accurately measured.

-

Useful for detecting surface scratches, deformations, or irregularities.

-

-

Metrology and Calibration:

-

Ensures accurate calibration of imaging systems for measurement tasks.

-

-

Inspection of 3D Objects:

-

Inspects objects with varying heights without introducing scaling errors.

-

-

High-Precision Assembly:

-

Verifies component alignment and assembly accuracy in industries like semiconductor manufacturing.

-

Key Features of Telecentric Lenses

-

Telecentric Design:

-

The entrance pupil of a telecentric lens is positioned at infinity, ensuring that light rays entering the lens are parallel. This design is key to eliminating perspective distortion.

-

-

Parallel Optical Axis:

-

Ensures uniform imaging across the entire field of view.

-

-

High Numerical Aperture (NA):

-

Allows for greater light collection, improving image brightness and detail.

-

-

Wide Field of View (FOV):

-

Capable of capturing larger areas without sacrificing resolution.

-

-

Customizable Working Distance:

-

Designed for flexibility to suit different inspection setups.

-

Applications of Telecentric Lenses in Industrial Machine Vision

-

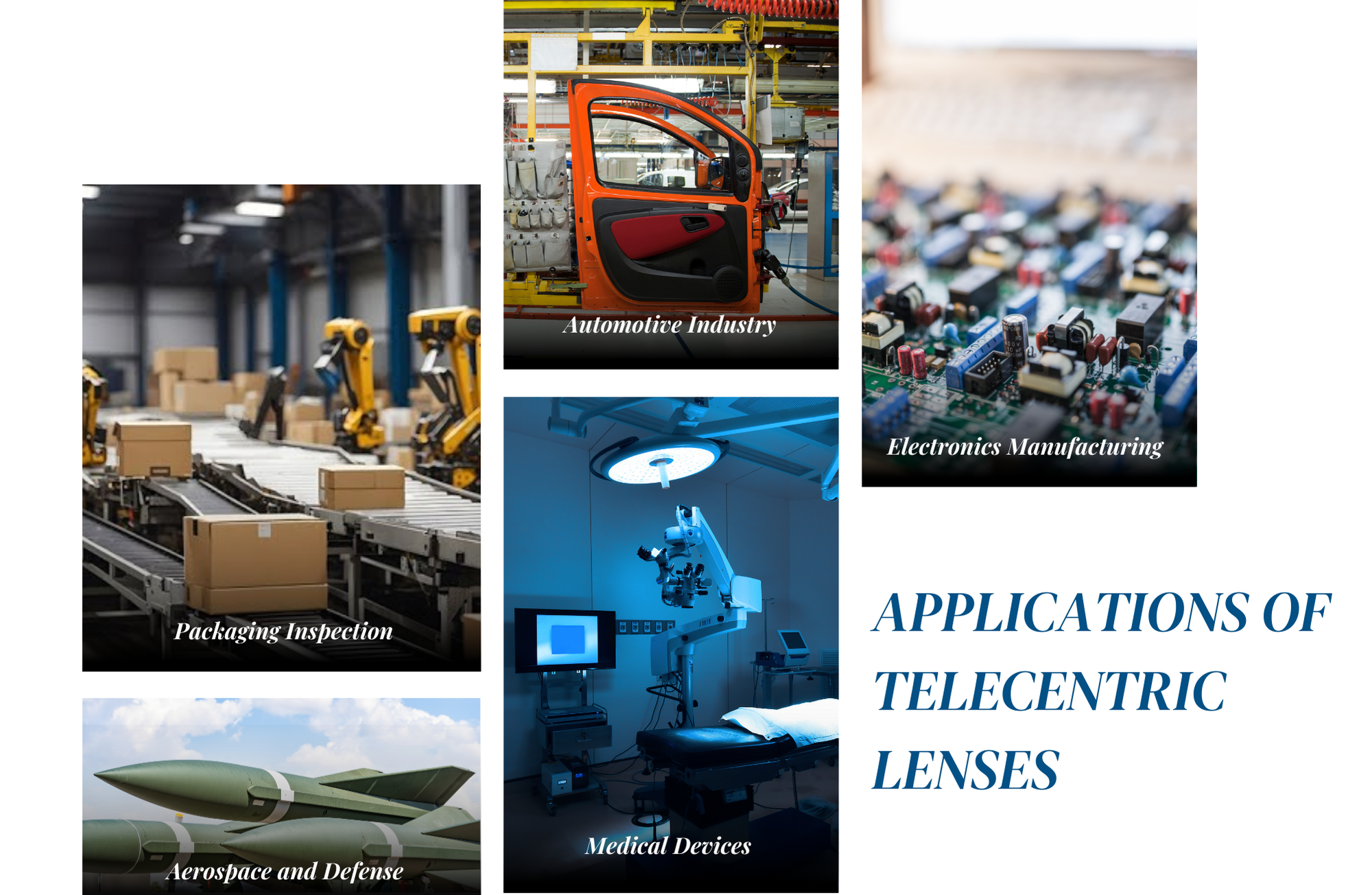

Electronics Manufacturing:

-

Inspection of PCBs, microchips, and connectors to ensure dimensional accuracy and detect defects.

-

-

Automotive Industry:

-

Gauging dimensions of engine parts, gears, and other precision components.

-

-

Medical Devices:

-

Ensuring the accuracy of implants, surgical tools, and diagnostic devices.

-

-

Packaging Inspection:

-

Verifying the integrity of labels, seals, and package dimensions.

-

-

Aerospace and Defense:

-

Inspecting critical components for uniformity and adherence to stringent quality standards.

-

Advantages of Using Telecentric Lenses

-

Enhanced Measurement Accuracy:

-

Eliminates errors caused by perspective distortion, critical for applications requiring exact measurements.

-

-

Improved Consistency:

-

Provides uniform imaging, ensuring reliable results across production lines.

-

-

Versatility:

-

Suitable for both 2D and 3D imaging tasks, making it a versatile choice for various industries.

-

-

High Precision in Defect Detection:

-

Detects and measures even the smallest defects with high accuracy.

-

-

Time and Cost Efficiency:

-

Reduces rework and material waste by ensuring high-quality outputs during the inspection process.

-

Considerations When Selecting a Telecentric Lens

-

Field of View (FOV):

-

Ensure the FOV matches the size of the object to be inspected.

-

-

Working Distance:

-

Choose a lens with a working distance suitable for the inspection environment.

-

-

Camera Sensor Compatibility:

-

Match the lens’s image circle with the camera’s sensor size to avoid vignetting.

-

-

Resolution Requirements:

-

Select a lens capable of resolving the smallest features or defects to be inspected.

-

-

Lighting Conditions:

-

Integrate appropriate lighting to maximize the lens’s performance.

-

Intelgic’s Expertise in Telecentric Lenses

At Intelgic, we specialize in providing tailored telecentric lens solutions for machine vision and defect detection applications. Our services include:

-

Lens Selection: Identifying the ideal telecentric lens based on application requirements.

-

System Integration: Ensuring seamless compatibility with cameras, lighting, and software.

-

Customized Solutions: Developing bespoke inspection systems to meet unique challenges.

-

Support and Training: Offering comprehensive support to optimize system performance.

Telecentric lenses are a cornerstone of precision imaging in industrial machine vision and defect detection. Their ability to maintain consistent magnification and eliminate perspective distortion makes them indispensable for high-accuracy applications. With Intelgic’s expertise, you can harness the full potential of telecentric lenses to enhance your inspection processes, ensuring consistent quality and operational efficiency.

Contact us today to learn how Intelgic can help optimize your machine vision systems with telecentric lens technology.