Stationary product inspection with Area Scan camera

Published on: Nov 08, 2024

Written by: Soumen das

Stationary product inspection with Area Scan camera

Understanding Area Scan Cameras

An area scan camera is a type of digital camera that captures a full frame in a single exposure using a two dimensional array of pixels, producing high-resolution images of objects within its field of view. Unlike line scan cameras, which capture images line-by-line and are better suited for moving or continuous inspection, area scan cameras capture a complete 2D image of a stationary object, making them ideal for applications where products are either stationary or briefly paused for inspection.

These cameras utilize image sensors, usually CMOS or CCD, to capture the entire scene at once. Each frame provides a detailed view of the product, allowing for comprehensive analysis and detection of defects, such as surface irregularities, incorrect dimensions, or color inconsistencies.

Key Components of Area Scan Cameras in Product Inspection

To understand the role of area scan cameras in stationary product inspection, it’s essential to look at the main components involved:

- Imaging Sensor: The heart of an area scan camera, responsible for capturing light and converting it into digital signals. Higher resolution sensors allow for more detailed inspection.

- Lens: The lens focuses light onto the imaging sensor. Selecting the right lens is crucial for ensuring that the camera captures the entire field of view with the necessary level of detail.

- Lighting System: Proper lighting is critical in stationary inspection to avoid shadows or glare that could interfere with defect detection. Many setups include LED lighting for even illumination.

- Processing Software: AI-based image processing software analyzes the captured images, identifying and classifying defects or anomalies within seconds. Intelgic has a state of the art AI model and a complete software suite for visual inspection. Intelgic’s software, Live Vision works with both area and line scan cameras.

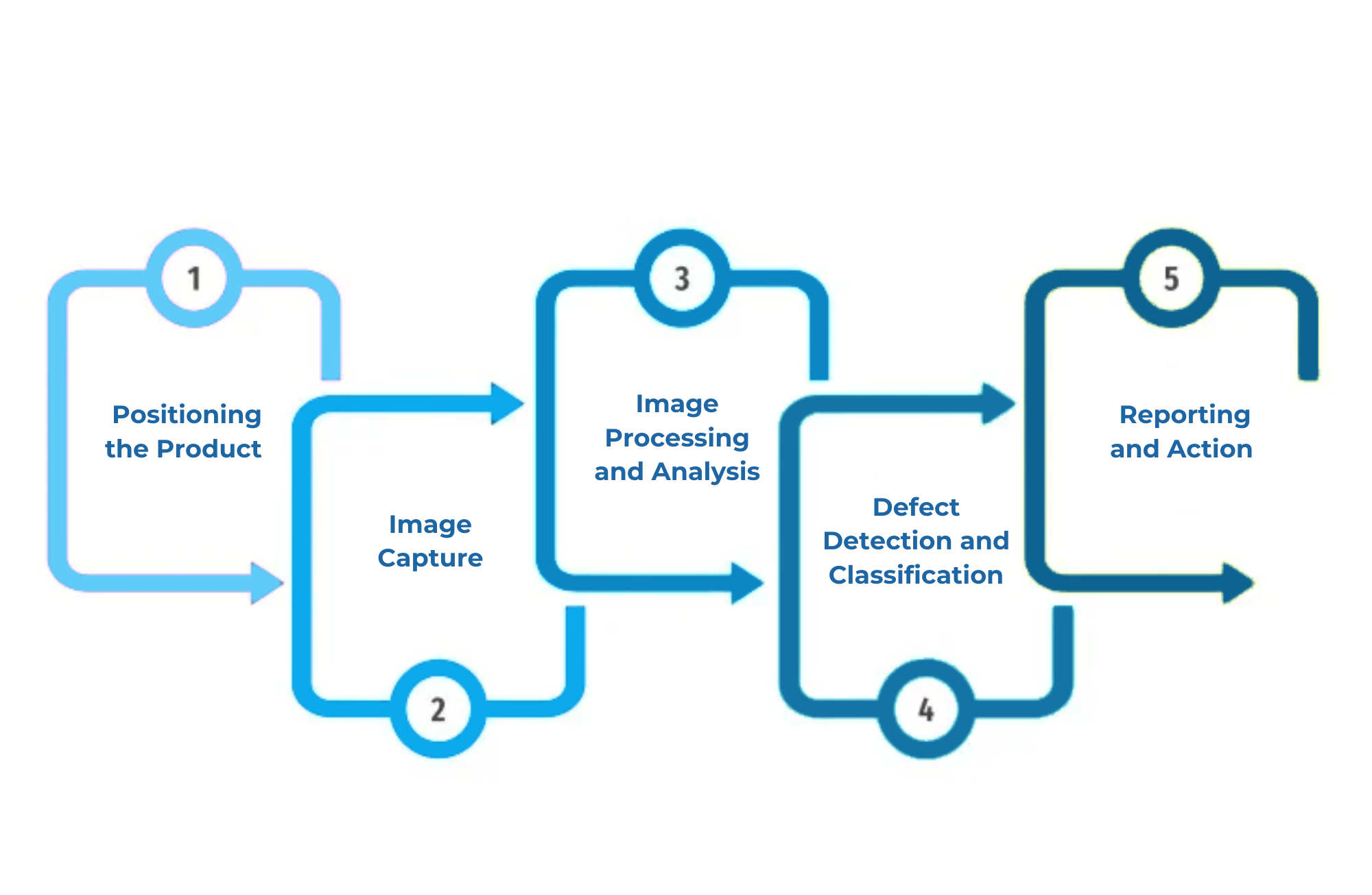

How Stationery Product Inspection Works with Area Scan Cameras

Stationary product inspection using area scan cameras involves several steps:

Positioning the Product

The product is positioned or placed on a stationary surface, conveyor belt, or inspection platform where it pauses momentarily for the camera to capture an image. In some setups, robotic arms or automated systems position the product under the camera for inspection.

Image Capture

The area scan camera takes a full image of the product in a single exposure, ensuring that every part of the product is captured in the frame. This is particularly useful for detecting surface defects, dimensional inconsistencies, and other visual anomalies that can compromise product quality.

Image Processing and Analysis

Once the image is captured, specialized software processes it, identifying any deviations from the expected standards. AI and machine learning algorithms are often employed to improve detection accuracy, allowing the system to differentiate between acceptable variations and actual defects.

Defect Detection and Classification

If the system detects an issue, it classifies the defect based on predefined criteria. For example, scratches, dents, and color inconsistencies can be flagged and categorized for review. This information is then relayed to a human inspector or an automated sorting system for further action.

Reporting and Action

If a defect is identified, the system can alert operators or reject the product from the production line. Additionally, the inspection data is stored for reporting and analysis, helping manufacturers to identify patterns in defects and address underlying causes.

Advantages of Area Scan Cameras in Stationary Product Inspection

Using area scan cameras in stationary product inspection offers numerous benefits, making them an appealing option for manufacturers looking to enhance their quality control processes:

a) High Image Quality and Resolution

Area scan cameras capture high-resolution images, enabling manufacturers to detect even the smallest defects. This is particularly valuable for industries that require detailed inspection of product surfaces, such as electronics and pharmaceuticals.

b) Fast Inspection Speed

With a single capture, area scan cameras can inspect an entire product in milliseconds. This rapid inspection capability helps manufacturers keep up with high production rates without compromising quality.

c) Cost-Effectiveness

For applications involving stationary products, area scan cameras are often more cost-effective than line scan cameras, as they don’t require continuous motion to capture the image. This reduces the complexity of the setup and lowers the overall inspection cost.

d) Flexibility Across Industries

Area scan cameras are versatile and can be adapted for use across various industries, including automotive, food and beverage, pharmaceuticals, and consumer electronics. They can inspect a wide range of product types, from small electronic components to larger automotive parts.

e) AI-Driven Inspection Capabilities

Integrating area scan cameras with AI and machine learning software allows for more intelligent inspection. AI algorithms can learn from past inspections, improving defect detection accuracy over time and adapting to new types of products or defects.

Common Applications of Area Scan Cameras in Different Industries

Stationary product inspection using area scan cameras is widely employed across several industries. Here are some common applications:

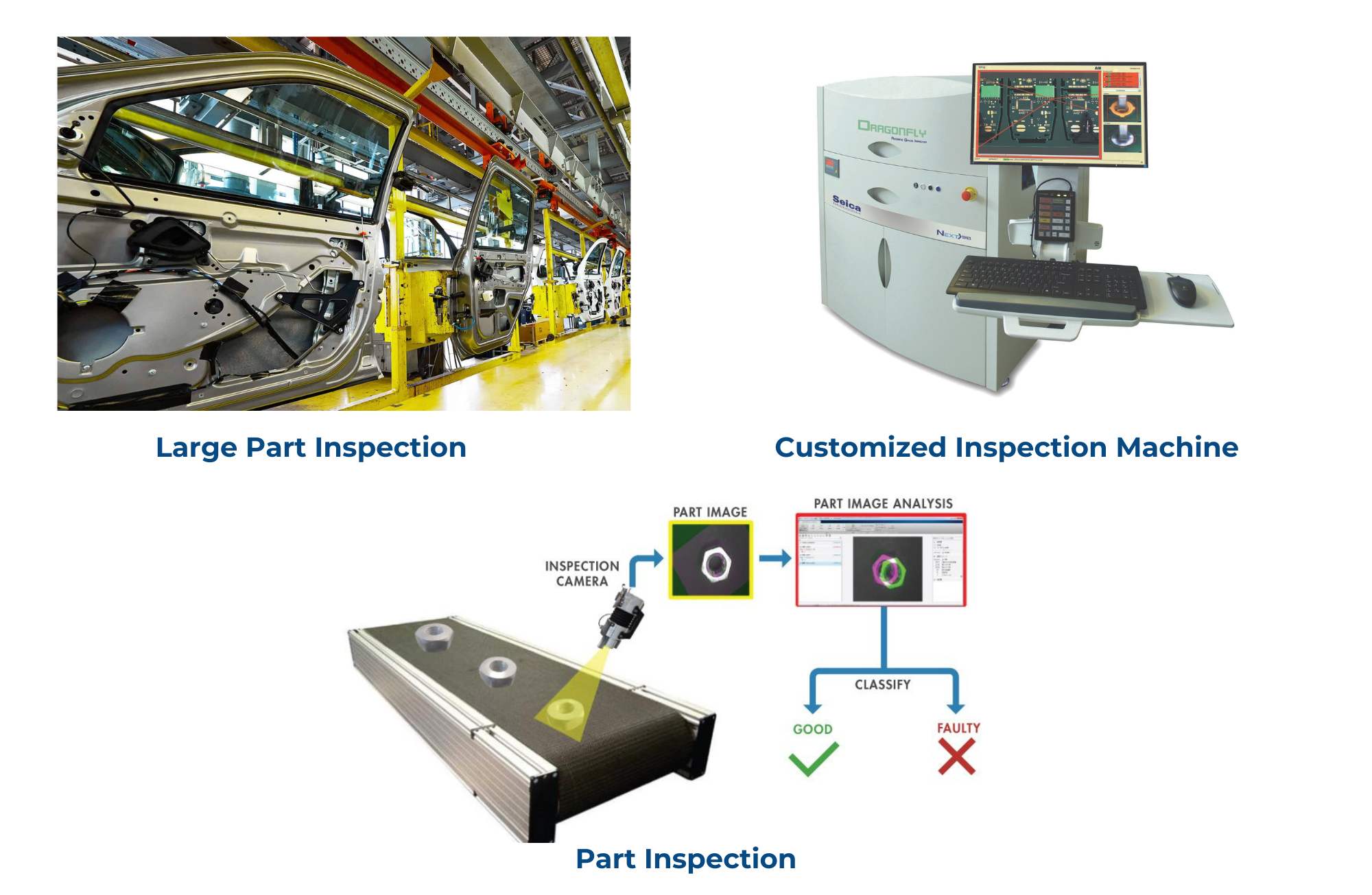

Part Inspection

In industries like automotive and machinery, area scan cameras enhance part inspection by providing high-resolution, detailed images of complex components inspected individually. Ideal for capturing surface defects, alignment issues, and dimensional accuracy, these cameras improve inspection efficiency and reliability.

Customized Inspection Machine

Area scan cameras are ideal for customized inspection machines where operators bring products inside the machine for inspection. These cameras capture detailed images in a single shot, making them suitable for examining complex or small parts. By providing high-resolution data on shape, size, and surface details, area scan cameras enable precise, automated quality, ensuring accuracy, consistency, and reliability in on-demand inspection processes.

Large Part Inspection

For large automotive parts like doors and bonnets, area scan cameras are highly effective in inspection booths or slow-moving inspection lines. These cameras capture high-resolution images in one shot, enabling detailed analysis of surfaces, edges, and fitment. Ideal for stationary or manually positioned parts, area scan cameras detect subtle defects or alignment issues, enhancing quality control by ensuring that large components meet stringent automotive standards.

Limitations of Area Scan Cameras

- Limited Field of View: Area scan cameras capture only small to medium size area at a time, which may require multiple images for larger objects, increasing inspection time.

- Lower Speed for Moving Objects: These cameras are less effective for fast-moving objects, as capturing high-quality images may require slowing down the production line.

- Lighting Sensitivity: Area scan cameras need stable, controlled lighting for clear images. Variations in lighting can lead to inconsistent or low-quality images.

- Higher Processing Requirements: High-resolution images can demand significant processing power and storage, which may increase system costs.

- Complex Setup for Large or Curved Surfaces: Area scan cameras can face challenges when inspecting large or irregular surfaces, requiring multiple cameras or complex setups.

- Higher Cost for Multi-Camera Systems: To cover larger areas, multiple cameras may be needed, raising system complexity and costs.

Stationary product inspection with area scan cameras represents a powerful tool for manufacturers striving to maintain high quality standards. With the ability to capture detailed images quickly and reliably, these cameras are well-suited for a range of industries where product consistency and precision are paramount. By investing in area scan cameras and integrating them with advanced software, manufacturers can enhance their quality control processes, reduce waste, and build trust with customers through consistent product quality.

As technology continues to evolve, area scan cameras will only become more capable, providing manufacturers with new opportunities to improve their production processes and meet the demands of a competitive marketplace.