Intelligent PCB Board Inspection Using Machine Vision and AI

Published on: Jul 16, 2025

Written by: Content team, Intelgic

Component Identification, Counting, and Defect Detection

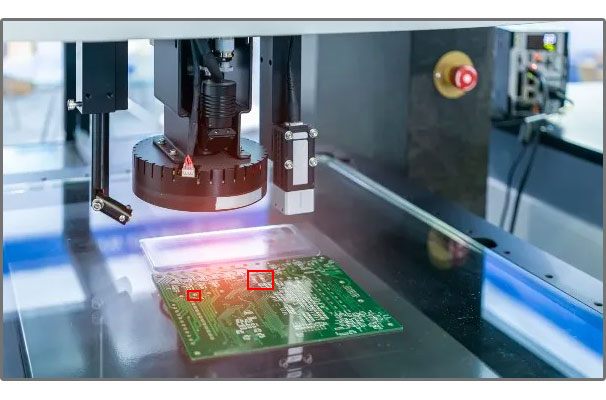

The Complexity of PCB Board Inspection

Printed Circuit Boards (PCBs) are at the heart of nearly every electronic device—from smartphones and medical equipment to aerospace systems and automotive ECUs. As PCBs become increasingly compact and densely populated, inspecting them for quality and accuracy has become both more critical and more challenging.

Manual inspection methods fall short due to the complexity and miniaturization of components. High-speed manufacturing lines demand real-time, high-precision inspection to catch subtle defects, misplacements, and errors before they become costly failures.

This is where Intelgic’s machine vision and AI-powered PCB inspection system delivers a transformative solution—combining high-resolution imaging, intelligent focus management, and deep learning algorithms to inspect, identify, count, and verify components, and to detect a wide range of defects on the PCB surface.

Challenges in PCB Imaging and Inspection

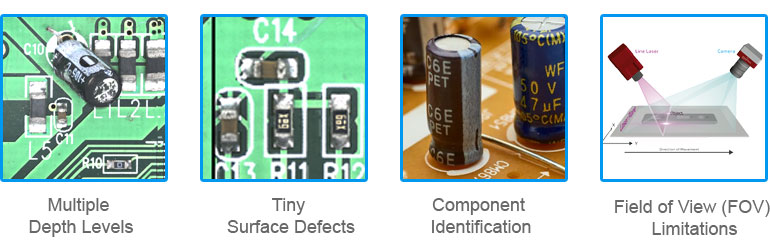

PCBs are multi-layered, populated with hundreds of tiny components of varying height, shape, and orientation. A few critical challenges include:

- Multiple Depth Levels: Components like chips, resistors, capacitors, connectors, and solder joints are located at different height levels.

- Tiny Surface Defects: Scratches, cracks, or delaminations in the substrate require microscopic-level imaging.

- Component Identification: Reading alphanumeric codes on microchips or capacitors requires precise focus and zoom.

Field of View (FOV) Limitations: A single camera shot cannot capture all areas in focus due to variations in Z-axis depth.

Intelgic’s Multi-Focus Machine Vision Inspection System

To overcome these challenges, Intelgic offers a complete PCB inspection solution that combines:

- High-resolution machine vision cameras

- Industrial-grade optics with zoom and telecentric lenses

- Custom lighting setups for clear contrast and illumination

- AI-driven multi-focus image stitching and analysis

Multi-Focus Imaging Technology

Intelgic’s system intelligently captures multiple images at different focus depths across the Z-axis. For example:

- For substrate inspection, it zooms into the flat surface to detect micro-cracks or surface irregularities.

- For component marking and number reading, it adjusts the focus to the chip or capacitor level.

All captured images are processed and stitched together using advanced software to generate a composite high-detail image of the entire board.

Key Capabilities of Intelgic’s PCB Inspection System

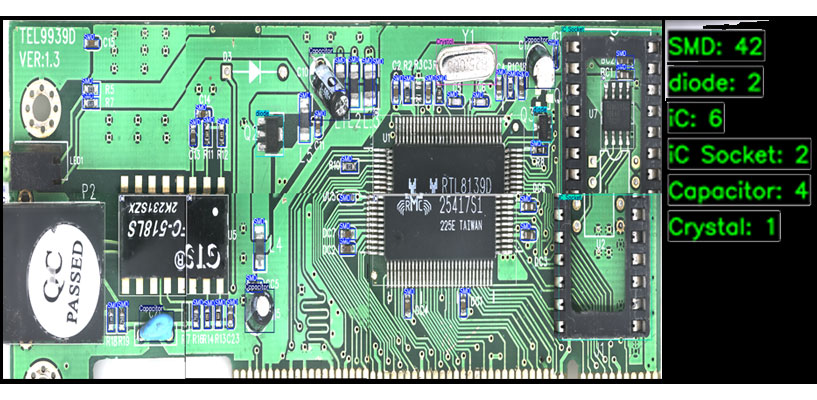

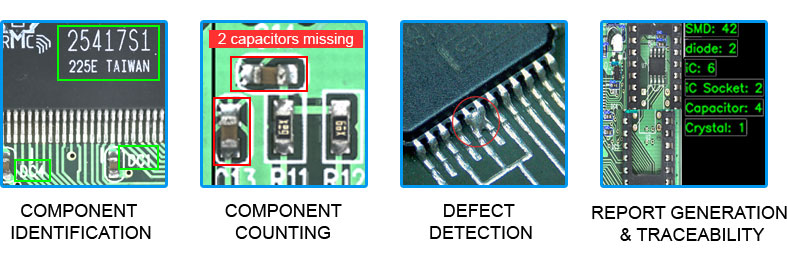

1. Component Identification

Intelgic’s AI software is trained to:

- Recognize different component types (e.g., SMDs, BGA chips, resistors, capacitors, connectors)

- Read markings or serial numbers on chips, diodes, and ICs

- Verify component positions and orientation against reference templates or BOM/CAD data

This ensures every component is present, correctly placed, and correctly labeled.

2. Component Counting

With pixel-level analysis and shape classification:

- The system automatically counts the number of each component type on the PCB

- Differentiates between visually similar parts using OCR on part markings

- Flags missing, extra, or misplaced components in real time

Component counting is critical in high-volume PCB production to ensure assembly integrity and accuracy.

3. Defect Detection

Intelgic’s inspection system identifies a wide range of visual and structural defects, including:

- Soldering defects:

- Cold solder joints

- Solder bridging

- Tombstoning

- Insufficient or excess solder

- Cold solder joints

- Surface defects:

- Scratches, delaminations, or pits in the PCB substrate

- Burn marks or discoloration

- Scratches, delaminations, or pits in the PCB substrate

- Component-related defects:

- Cracked resistors or capacitors

- Misaligned or inverted ICs

- Lifted leads or bent pins

- Cracked resistors or capacitors

Using AI-based anomaly detection and comparison with defect-free templates, the system ensures even subtle, non-obvious defects are captured.

4. Report Generation and Traceability

Each inspection run generates a comprehensive report that includes:

- Annotated images with defects and anomalies highlighted

- Component counts and identification log

- Pass/fail status of each board

- Timestamp and inspection ID

- Integration-ready data for MES or ERP systems

All reports are stored in the cloud or locally based on configuration, enabling full traceability for audits, warranty claims, and quality analytics.

Hardware and Software Components

Intelgic’s complete solution includes:

- Machine Vision Cameras: Up to 20MP resolution for microscopic detail

- Motorized Lens Systems: For programmable focus adjustment

- Industrial Lighting: Dome, ring, coaxial, and dark field options for perfect contrast

- AI Inspection Software: Real-time processing, defect classification, component matching

Inspection Machine Integration: Conveyor-based or static inspection units

Benefits to Electronics Manufacturers

High Inspection Accuracy: Capture all critical visual data from every layer of the PCB

Real-Time Feedback: Catch errors early in the line to reduce rework and scrap

Scalable and Configurable: Works with various PCB sizes, designs, and component layouts

Data-Driven Quality Control: Use inspection trends to optimize process and vendor performance

Complete Traceability: Supports compliance with IPC, ISO, and industry regulations

Use Cases and Applications

- Consumer Electronics PCB Inspection: Phones, tablets, gaming devices

- Automotive Electronics: ECUs, infotainment, BMS boards

- Medical Devices: Implantable sensors, diagnostic boards

- Aerospace Systems: Avionics, control boards

- Industrial Controls: PLCs, embedded systems, HMI boards

Precision Meets Intelligence in PCB Inspection

PCB boards are among the most complex and mission-critical components in any electronic product. Ensuring their integrity requires more than basic visual checks — it requires multi-focus, AI-enhanced inspection that captures the tiniest flaws and verifies every component.

With Intelgic’s advanced machine vision and AI inspection solution, electronics manufacturers gain:

- Unparalleled imaging clarity

- Intelligent focus adjustment across depth layers

- Powerful defect and component analysis

- Full documentation and traceability

From microscopic scratches to missing microchips — Intelgic sees it all.

Let Intelgic help you deliver zero-defect PCBs with confidence and speed.