Next generation quality inspection automation

Automating Industrial Processes with AI-Powered Vision Systems

Intelgic is a cutting-edge industrial automation company focused on AI-based visual inspection and process intelligence. We specialize in designing and developing custom Automated Optical Inspection (AOI) systems that seamlessly integrate machine vision, industrial optics, precision robotics, and AI-powered software to automate visual inspection processes and drive manufacturers toward Zero Defect Manufacturing.

Our solutions are engineered to handle the complexity and variability of real-world production environments—across materials, shapes, finishes, and industries.

Scratches, pinholes, cracks, misalignments, contamination

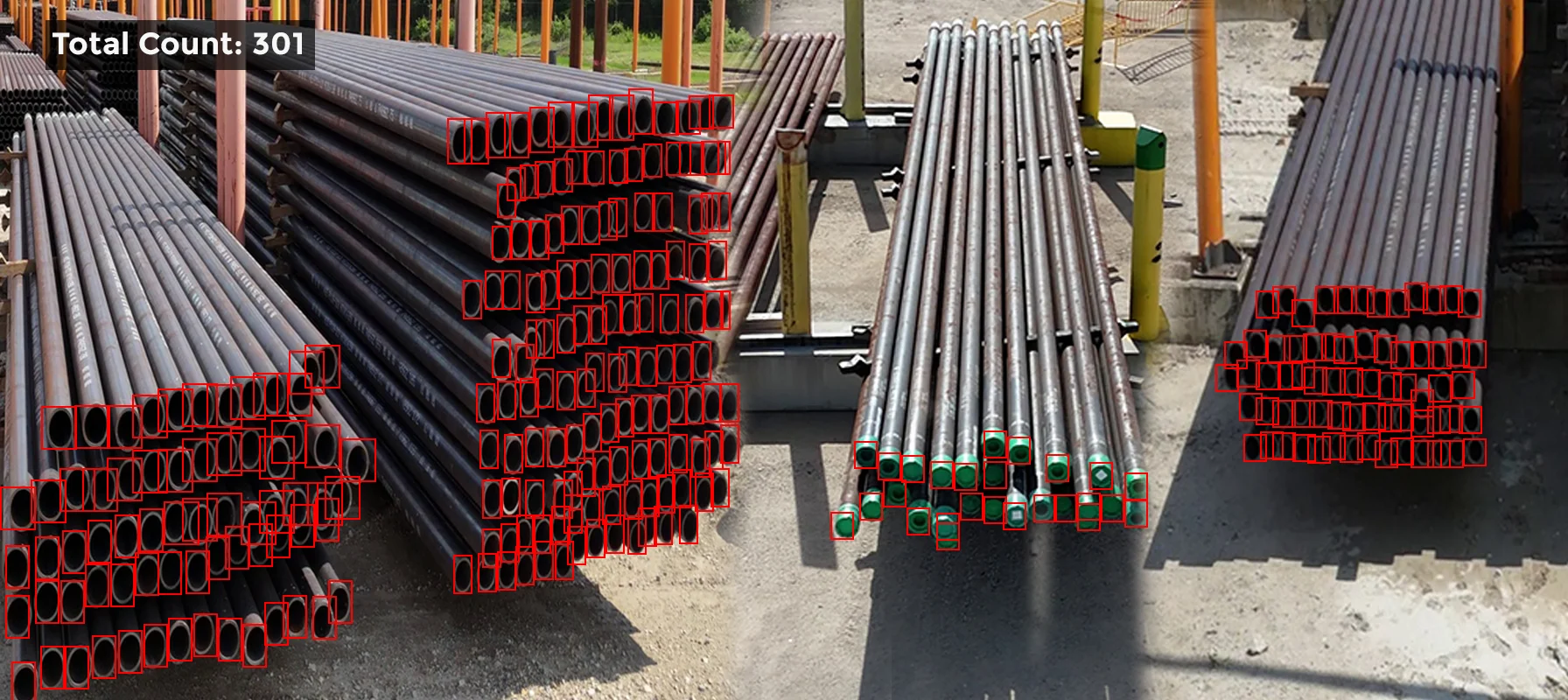

Pipes, products, PCB components, packages

Length, width, diameter, gap, displacement using vision AI

Product IDs, vehicle numbers, labels, and barcodes

Custom reports with pass/fail logic and image proof

Real-time inspection reports, defect analytics, digital quality certificates

Complex metal and plastic part inspection

Microscopic defect detection in sensitive products

SOP monitoring, component verification, assembly QC

Pipe/tube counting, bore inspection, sheet inspection

PCB inspection, component counting, solder defect detection

Inventory movement tracking, bag/box counting

Engineered AOI solutions—not one-size-fits-all kits

Machine vision hardware and imaging physics specialists

Scalable AI built for industrial environments

APIs for MES, ERP, and PLCs

On-prem or cloud based on your infrastructure

Design, hardware, software, installation, and training

Automated inspection of machined components

Detect scratches and defects in optical components

Automated counting at loading docks and warehouses

Quality control for printed circuit boards

Automated quality checks for medical products

Monitor inventory movement in real-time

"We have been utilizing the Intelgic platform for about a year now. Their offering has become an intricate roll within our day to day operations. Between their base offerings & working with us to develop some additions tools to API with our platform they have saved us hours of labor daily within our data entry processes. They truly have been a game changer for us!"

Tyler Sumner

Founder | CEO

link-x.com

"We have used Intelgic to create technology and bots to automate key processes in our business that have saved thousands of man hours and allowed us to do things we never could scale. They work efficiently and quickly and are very collaborative."

Ryan Teeples

Fintech CTO

1-800Accountant

One of the world’s largest automotive parts manufacturers replaced manual inspection with Intelgic’s AI-powered vision system. Using robotic motion, specialized lighting, and advanced ...

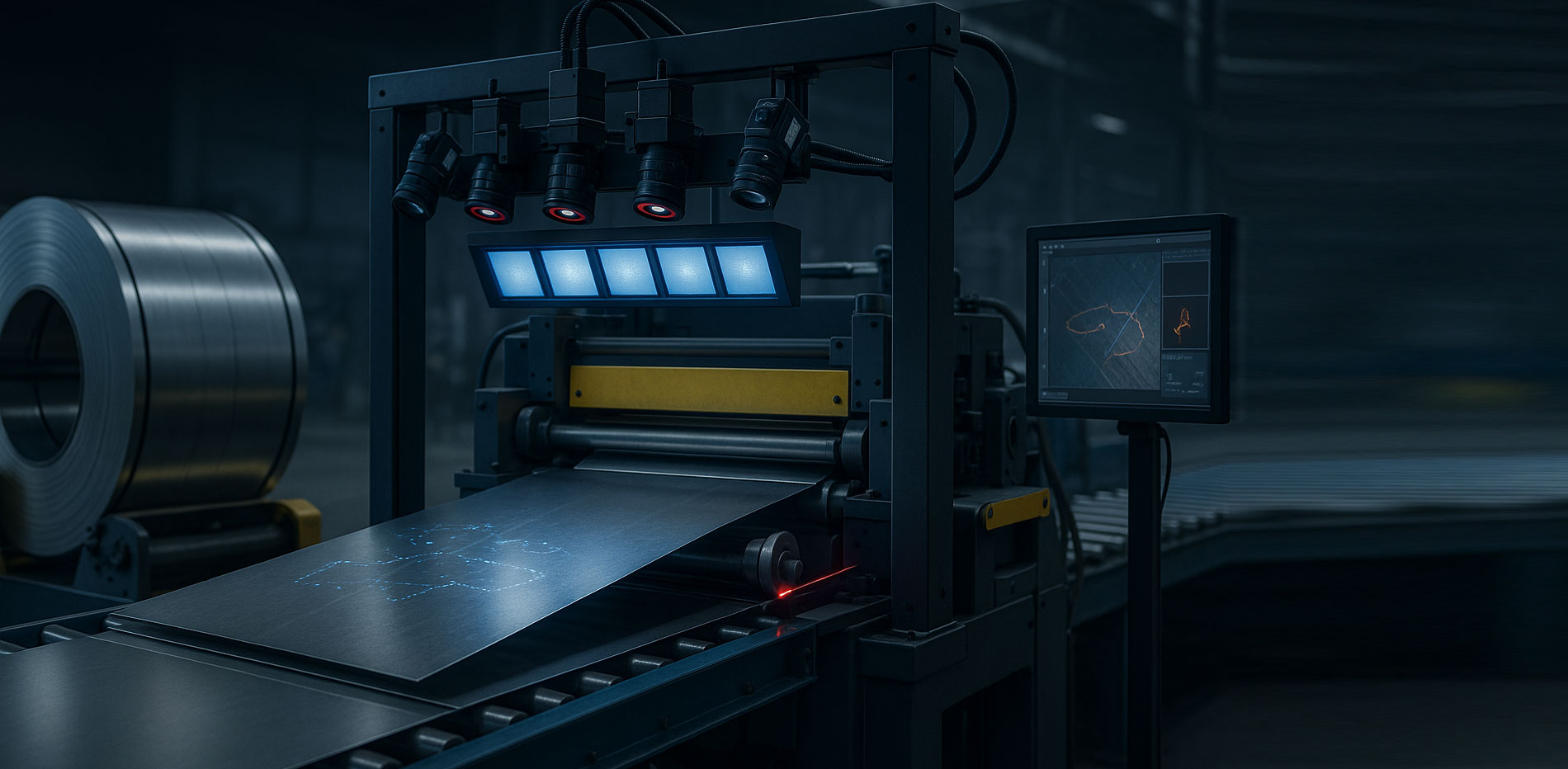

At one of the world’s leading steel plants, the Cut-to-Length (CTL) process was a critical stage in turning massive coils into perfectly measured steel sheets. Each coil, sometimes over 2 meters wide...

A large UK based industrial gas manufacturer wanted to monitor their driver’s activities while they are driving and classify their activities into different categories such as micro sleeps..

Our client, one of the largest pipe manufacturers globally, operates a big facility in Texas, USA.

Inspecting the inner surface of metal tubes is one of the most critical quality assurance tasks in industries such as oil & gas, aerospace, medical devices, chemical processing, and power generation...

Read the full article©2025 Intelgic Inc. All Rights Reserved.