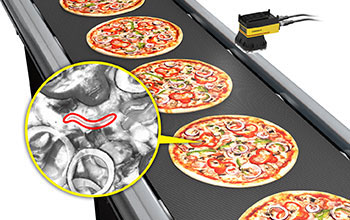

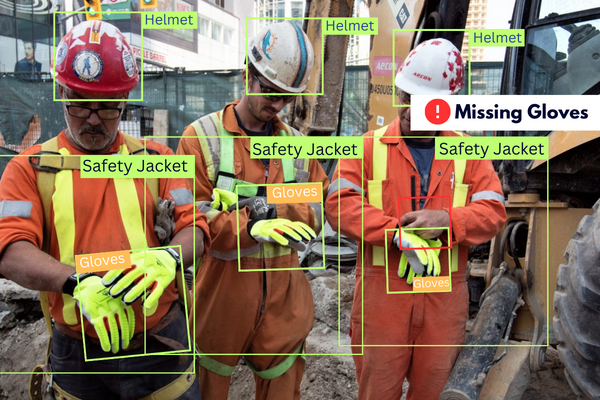

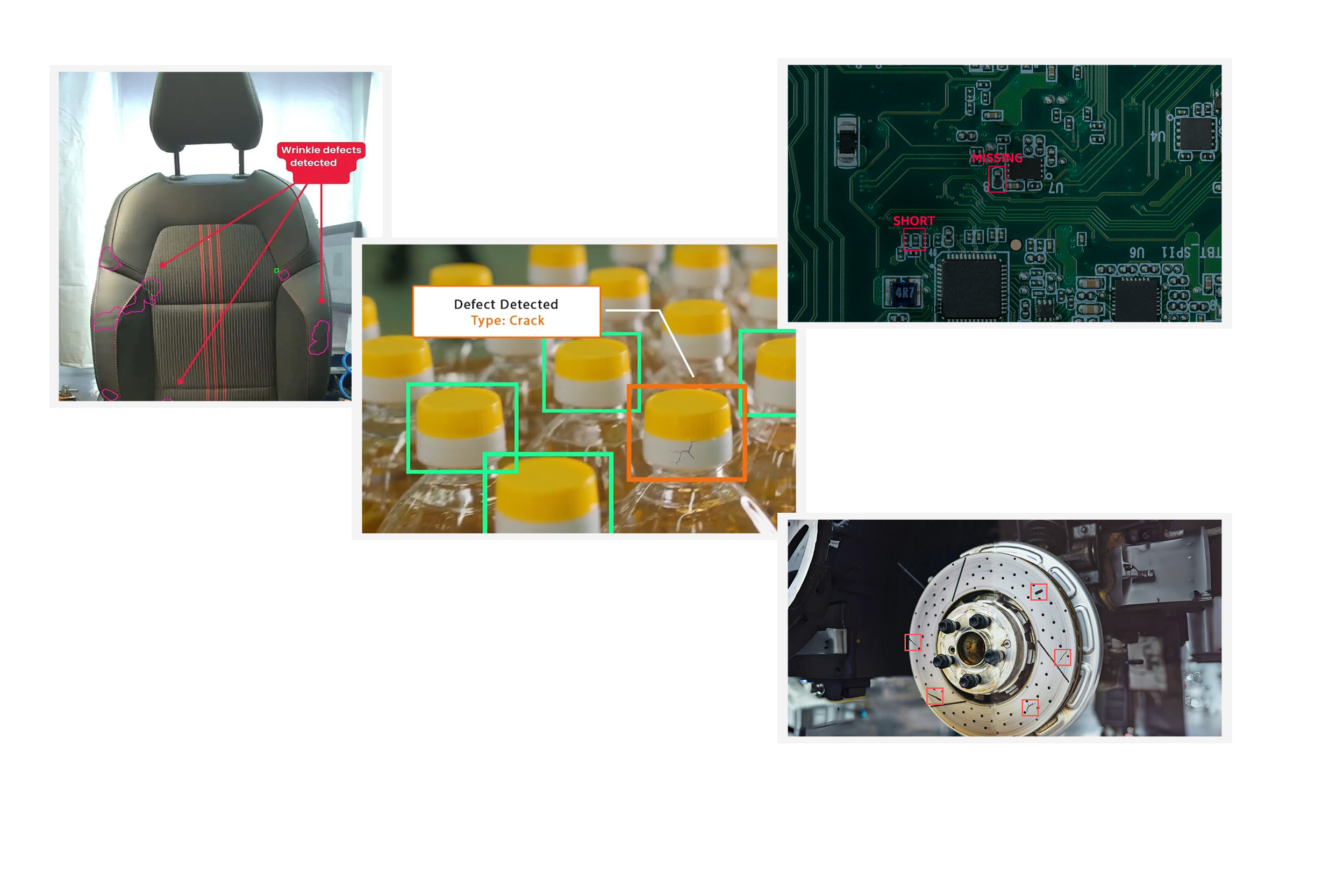

Product defect detection through visual inspection using vision AI

Detect anomalies and defects within your products by automating the visual inspection process using Vision AI technology. Visual inspection is implemented in various manufacturing industries including pharmaceuticals, electronics, building materials, electricals, automotive, food production and others where quality control is a primary focus.

- Surface defect detection

- Detect scratches, dents, cracks, dirts and many more

- Detect color coding, capping errors, packaging errors etc.

- Detect foreign objects, change in color, burning areas, smoke etc. in the food production.

- Detect labeling errors, read labels, bar code, QR code and verify information.

- Integrate Intelgic’s Vision AI to your existing system.