Threading Holes Measurement Using Laser Sensors

Published on: Nov 13, 2024

Written by: Soumen das

Threading Holes Measurements Using Laser Sensors

Threaded holes are a common feature in manufacturing across industries such as automotive, aerospace, electronics, and machinery production. Ensuring these threaded holes meet precise specifications is crucial for product quality and performance. Traditionally, inspection of threaded holes was done manually or using contact-based tools like gauges and probes. However, these methods can be slow, prone to error, and challenging to apply consistently in high-volume production. Laser sensor technology offers a non-contact, accurate, and efficient solution for measuring threaded holes, transforming inspection processes. This article delves into the methods, benefits, and applications of laser sensors for measuring threaded holes in modern manufacturing.

Overview of Laser Sensor Technology

Laser sensors are optical devices that use laser beams to measure distance, surface texture, and dimensions. These sensors can operate based on various principles, such as:

-

Triangulation: Measures the angle between a laser beam emitted onto a surface and the light reflected back, which is processed to determine the distance.

-

Time-of-Flight (ToF): Measures the time taken for a laser pulse to travel to an object and return, calculating distance based on the speed of light.

-

Confocal Chromatic Imaging: Uses different wavelengths of light to determine the distance to specific points on an object, allowing for high precision in 3D measurements.

For threaded hole inspection, laser sensors often utilize triangulation and confocal methods due to their accuracy in capturing fine details and ability to operate at close distances.

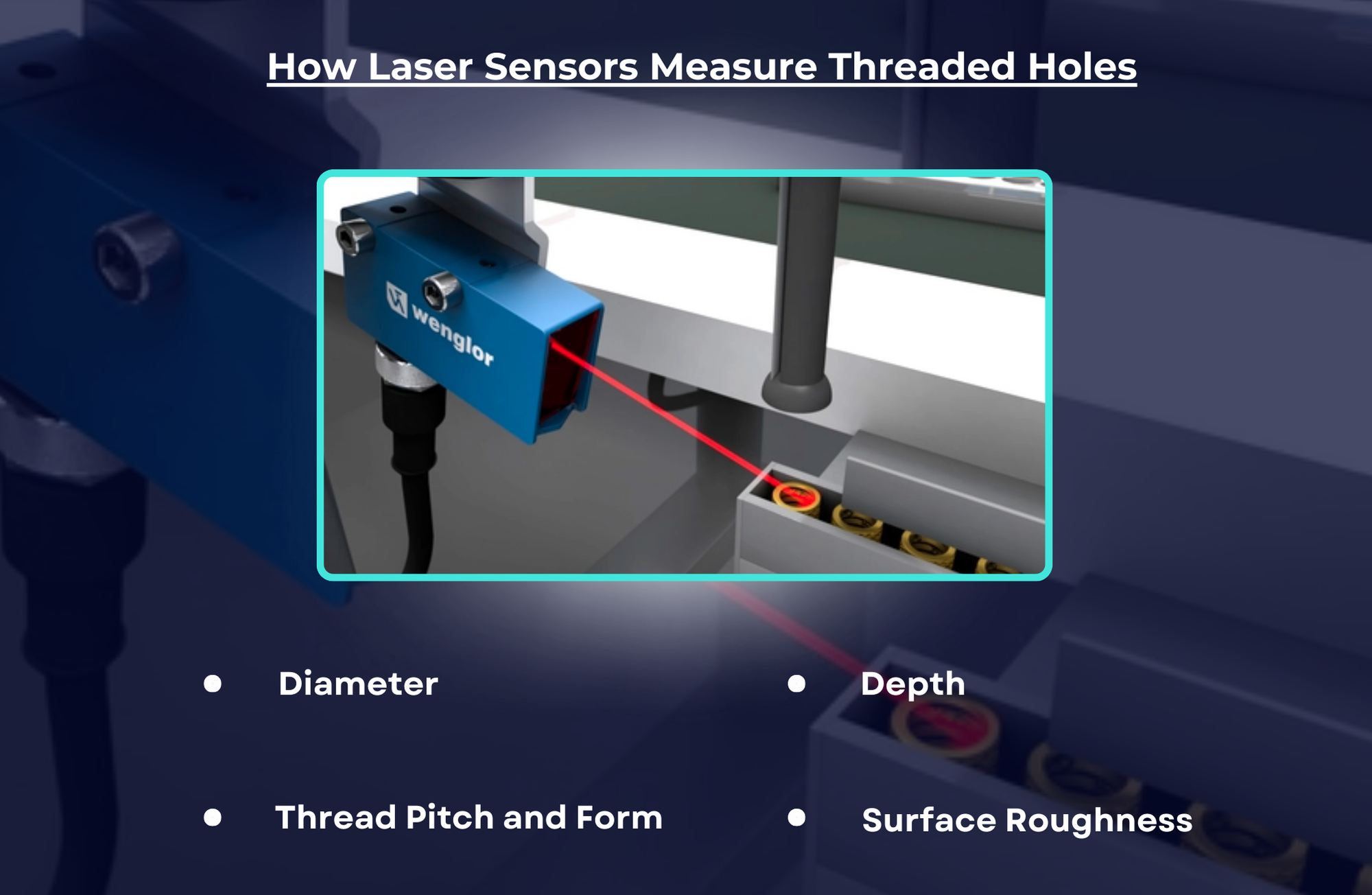

How Laser Sensors Measure Threaded Holes

Measuring threaded holes with laser sensors typically involves creating a 3D map of the hole’s geometry. The laser sensor emits a focused beam into the hole, and as the light reflects off the walls of the hole and threads, the sensor captures detailed data points. These points are then processed to form a digital profile of the hole, allowing for precise measurements of:

-

Diameter: Laser sensors accurately measure the inner and outer diameters of the threaded hole.

-

Depth: They determine the hole depth by calculating the distance from the surface to the bottom of the hole.

-

Thread Pitch and Form: Laser sensors can capture the pitch (distance between threads) and ensure the threading conforms to design specifications.

-

Surface Roughness: In some cases, laser sensors are also capable of measuring surface texture, which can indicate threading quality.

The data collected by laser sensors can be analyzed immediately, enabling real-time quality control and quick corrective actions if defects are detected.

Applications of Laser Sensors in Threaded Hole Measurement

Laser sensors are employed in various industries for threaded hole inspection due to their precision and adaptability. Some specific applications include:

Automotive Manufacturing

In the automotive industry, threaded holes are essential for fastening engine components, body panels, and electronic parts. Laser sensors can inspect these holes to ensure they meet quality standards, reducing the risk of assembly issues that could affect vehicle safety or performance.

Aerospace Industry

Threaded holes in aerospace components require strict tolerance adherence due to the safety-critical nature of the industry. Laser sensors provide the necessary precision to inspect these holes and ensure they meet regulatory standards for safety and reliability.

Medical Device Manufacturing

Medical devices with threaded holes, such as implantable devices or surgical tools, need to meet stringent quality standards to ensure patient safety. Laser sensors enable precise inspection of these threaded holes, helping manufacturers adhere to regulatory requirements.

Machine and part Manufacturing

Laser sensors are crucial for inspecting threading holes in machines and machine parts, offering precise, non-contact measurements of depth, alignment, and threading integrity. They swiftly detect defects like irregular threading and misalignment, ensuring components meet strict specifications.

Steps for Implementing Laser-Based Threaded Hole Inspection

Implementing laser-based inspection for threaded holes requires a systematic approach:

-

Determine Inspection Requirements: Identify the key dimensions and tolerances for the threaded holes, as well as the production volume and speed. This will guide the selection of laser sensors.

-

Select the Appropriate Laser Sensor: Based on the hole size, depth, and thread type, choose a laser sensor that meets the accuracy and range requirements. Consider factors like triangulation or confocal methods based on the level of detail needed.

-

Integrate the Sensor with the Software: Laser sensors generate digital data that needs to be analyzed. Integrate software that can process this data to evaluate hole dimensions, depth, and threading quality.

-

Calibrate and Test: Ensure the sensor is properly calibrated for the specific materials and threading features. Conduct test measurements to verify accuracy and adjust settings as needed.

-

Train Operators: Train staff to operate, maintain, and interpret results from the laser-based inspection system. Operators should also know how to troubleshoot common issues.

-

Implement Quality Control Feedback: Use data collected from inspections to make real-time adjustments to production, helping to reduce defect rates and improve overall quality.

Benefits of Using Laser Sensors for Threaded Hole Inspection

Using laser sensors for threaded hole measurement provides multiple advantages:

Non-Contact Measurement

One of the most significant benefits of laser sensors is their non-contact nature. Unlike probes or gauges that need to touch the surface, laser sensors can inspect threaded holes without any physical interaction. This eliminates the risk of damaging sensitive parts or altering the measurement results due to mechanical contact.

High Precision and Accuracy

Laser sensors offer sub-micrometer precision, enabling highly accurate measurements even for small threaded holes or those with tight tolerances. This level of precision is challenging to achieve consistently with traditional inspection methods.

Speed and Efficiency

Laser sensors can capture thousands of data points per second, allowing for rapid measurements of complex geometries. This makes them ideal for high-volume production environments where speed is essential.

Flexibility and Adaptability

Laser sensors are capable of inspecting various thread types and sizes. They can easily switch between measurements of different holes without the need for physical reconfiguration, making them highly adaptable in multi-part production settings.

Data Collection and Analysis

Laser sensors generate digital data that can be stored, analyzed, and used to improve quality control processes. With data on every measured hole, manufacturers can identify patterns, make adjustments to production, and reduce defect rates.

Challenges and Considerations in Laser-Based Threaded Hole Inspection

While laser sensors offer numerous benefits, there are challenges and considerations in their application:

Surface Reflectivity

Highly reflective or transparent surfaces can interfere with laser measurement. To address this, manufacturers may use anti-reflective coatings or adjust sensor settings to ensure accurate readings.

Limited Depth Range

Some laser sensors may struggle with measuring deeper holes due to limitations in focusing capabilities. In such cases, specialized sensors or multiple sensors from different angles may be required to capture the full depth accurately.

Cost of Implementation

Laser sensors, especially high-precision models, can be costly. However, the long-term benefits of reduced defects, increased accuracy, and higher throughput can offset the initial investment.

Environmental Conditions

Dust, vibrations, and temperature fluctuations can impact the accuracy of laser measurements. Proper installation, calibration, and maintenance are essential to maintain optimal sensor performance.

Future Trends in Laser-Based Threaded Hole Inspection

The use of laser sensors for threaded hole inspection is likely to evolve with advancements in sensor technology, AI, and machine learning. Future systems may include:

-

AI-Driven Analysis: Machine learning algorithms could further improve defect detection by analyzing patterns in laser data and predicting potential quality issues before they occur.

-

IoT Integration: Connecting laser sensors to an IoT network would enable real-time monitoring and data sharing across production lines, allowing manufacturers to react immediately to quality control issues.

-

Miniaturized and Compact Sensors: As sensor technology advances, laser sensors may become smaller and more affordable, making them accessible to a broader range of industries and applications.

Laser sensors have transformed the inspection of threaded holes, offering a fast, precise, and non-contact solution for ensuring product quality. By capturing detailed measurements and threading information, laser-based systems provide manufacturers with valuable data for quality control, reducing the risk of defects and improving production efficiency. Although there are challenges in implementation, the advantages in terms of accuracy, speed, and data analysis make laser sensors an ideal choice for modern manufacturing environments. As technology progresses, laser-based inspection methods will continue to improve, paving the way for even more advanced and integrated quality control systems.