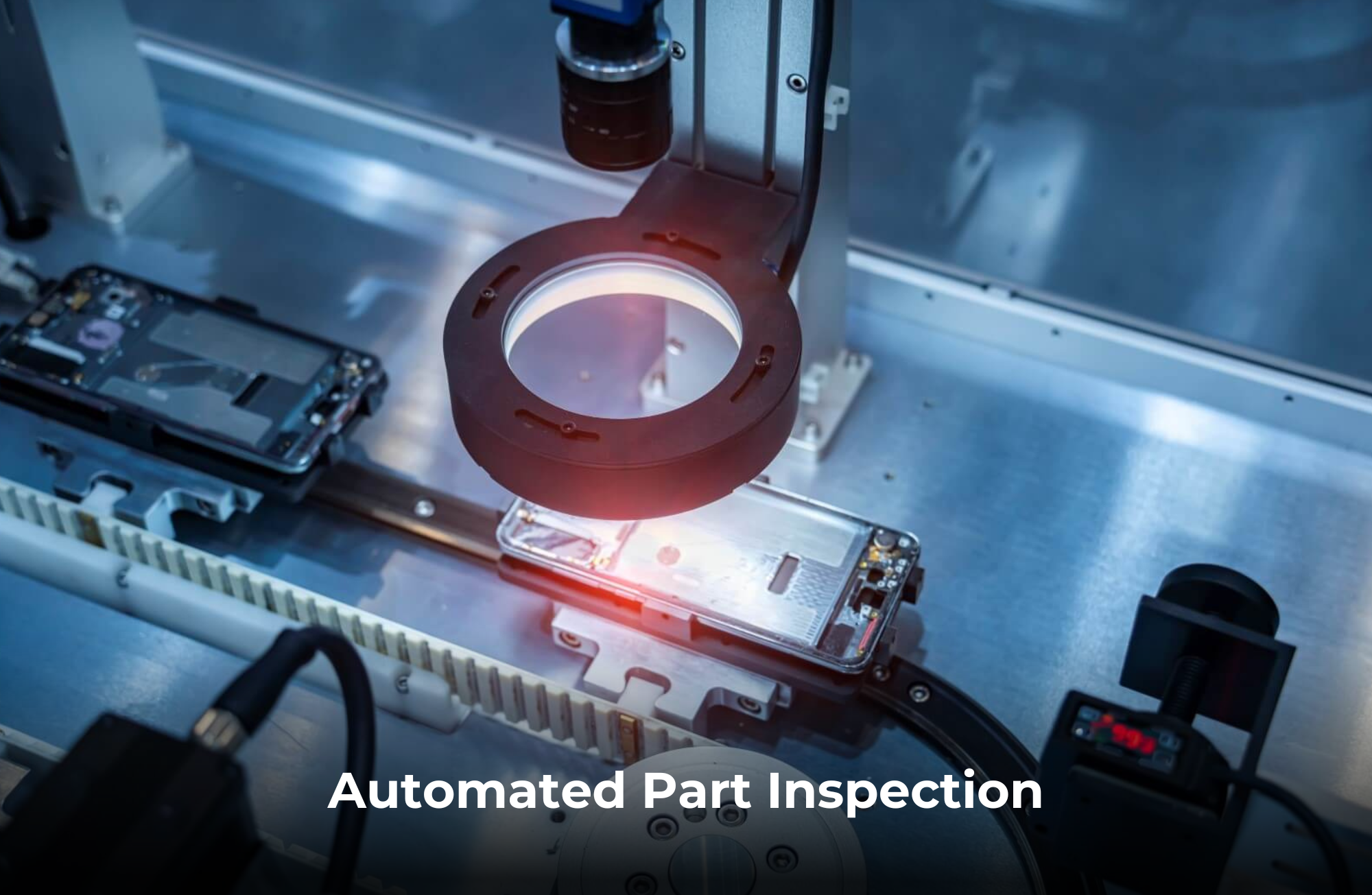

Part Inspection using AI powered Automated Optical Inspection (AOI) System

Published on: Oct 23, 2024

Written by: Soumen das

Part Inspection Using AI-Powered AOI System and Machine Vision Technology: A Comprehensive Guide

In modern manufacturing, quality and precision are critical. Maintaining product quality while keeping up with high-speed production lines can be challenging for traditional manual or mechanical inspection methods. Automated Optical Inspection (AOI) systems, powered by Artificial Intelligence (AI) and machine vision technology, are revolutionizing the way manufacturers detect defects and ensure product quality. This cutting-edge approach not only increases accuracy but also allows for real-time, high-speed inspection of complex parts across various industries.

In this article, we’ll explore how AI-powered AOI systems and machine vision technology are used for automated part inspection, why they are superior to traditional methods, the core components and technologies involved, and the benefits they bring to manufacturers.

What is Automated Part Inspection?

Automated part inspection refers to the process of using advanced systems—such as machine vision, AI algorithms, and optical sensors—to inspect and verify the quality and integrity of manufactured parts. This process can identify defects, measure dimensions, ensure proper assembly, and verify the correct placement of components. In industries such as automotive, electronics, aerospace, and medical devices, part inspection is essential to maintain quality standards, ensure safety, and meet regulatory compliance.

Traditionally, part inspection was conducted manually by human inspectors or through mechanical methods, which often led to inefficiencies, human errors, and slower production times. However, with the rise of AI-powered AOI systems and machine vision technology, manufacturers can now automate the entire inspection process, making it faster, more accurate, and adaptable to different production environments.

How Does an AI-Powered AOI System Work in Part Inspection?

An AI-powered AOI system is an automated inspection system that combines machine vision technology with AI algorithms to detect defects, measure parts, and ensure product quality in real-time. Here’s a breakdown of how these systems operate:

1. Image Acquisition

The first step in an AI-powered AOI system is image acquisition, where high-resolution machine vision cameras capture images or video frames of the part being inspected. Different types of cameras and imaging technologies are used depending on the inspection needs, including 2D, 3D, infrared, and X-ray imaging. Proper lighting and optics are essential in this step to highlight defects or irregularities in the part.

2. Image Processing

Once the image is captured, the system processes the image using advanced image processing algorithms. Techniques such as filtering, noise reduction, and contrast enhancement are applied to ensure that the image is clean and suitable for further analysis. Edge detection, blob analysis, and contour mapping are used to extract important features such as part dimensions, surface quality, and placement accuracy.

3. AI-Powered Defect Detection

At the core of the system is the AI algorithm, typically a Convolutional Neural Network (CNN) trained to recognize patterns and features indicative of defects. During the training phase, the system is fed thousands of images, both defective and non-defective, enabling the AI to learn how to identify potential flaws such as cracks, scratches, misalignments, and other anomalies.

AI enables the system to detect not only obvious defects but also subtle imperfections that might be difficult for traditional systems or human inspectors to recognize. Moreover, AI can adapt to variations in part design, material, or production conditions, making the system more flexible and accurate over time.

4. Classification and Decision-Making

Once the system detects a defect, the AI model classifies it based on predefined criteria such as severity, type, and location. The system then makes a decision on whether the part should pass inspection, be flagged for rework, or be rejected entirely. This decision is communicated to the production line in real-time, enabling immediate corrective action.

5. Real-Time Feedback and Reporting

The system generates real-time feedback, allowing operators to address issues as they arise. Additionally, the system saves images and inspection data for future analysis and quality control. Manufacturers can use this data to analyze trends, optimize processes, and improve product quality over time.

.png)

Key Technologies Behind AI-Powered AOI and Machine Vision

AI-powered AOI systems rely on a combination of advanced technologies to perform part inspection:

1. Machine Vision Cameras

Machine vision cameras are the backbone of automated part inspection. They capture high-resolution images of the parts being inspected, enabling the system to detect even the smallest defects. Depending on the application, manufacturers use 2D cameras for flat surfaces or 3D cameras for complex, multi-dimensional parts. These cameras are equipped with various optics and lighting solutions to ensure the best possible image quality.

2. AI and Deep Learning

Artificial Intelligence, specifically deep learning, is at the heart of defect detection in AI-powered AOI systems. By training deep learning models such as CNNs, the system can learn from large datasets of images, enabling it to recognize patterns, textures, and defects in real-time. Deep learning models are capable of handling complex inspection tasks, such as detecting cracks, discoloration, deformations, or foreign objects on the surface of the part.

3. Image Processing Algorithms

Image processing techniques, including edge detection, morphological filtering, and histogram analysis, are used to prepare images for defect detection. These algorithms enhance the quality of the images, making it easier for the AI model to accurately analyze and detect defects.

4. Optical Sensors and Lighting Systems

Proper lighting is crucial for successful part inspection. Structured lighting, bright-field or dark-field illumination, and laser profiling are commonly used to highlight surface defects or dimensional discrepancies. Optical sensors play a critical role in measuring part dimensions, alignment, and surface quality.

5. Real-Time Data Processing

Edge computing technologies enable the AI-powered AOI system to process data at the source, providing real-time feedback to production lines. This ensures that defects are identified and corrected immediately, reducing downtime and preventing defective parts from moving further down the production chain.

Applications of AI-Powered AOI Systems in Part Inspection

AI-powered AOI systems are used across a variety of industries where precision and quality control are essential. Here are some key applications:

1. Automotive Industry

In the automotive sector, parts such as engine components, braking systems, and transmissions need to meet stringent safety and performance standards. AI-powered AOI systems inspect metal surfaces, detect cracks, and ensure dimensional accuracy in automotive parts, ensuring that only high-quality components are assembled into vehicles.

2. Electronics and PCB Inspection

In electronics manufacturing, particularly in the production of printed circuit boards (PCBs), AOI systems detect soldering defects, missing components, and incorrect placements. The ability of AI to learn from different defect types makes it invaluable in ensuring the reliability of electronics.

3. Aerospace and Aviation

In aerospace, where safety is critical, AI-powered AOI systems inspect aircraft components for material flaws, dimensional irregularities, and surface imperfections. The ability to detect defects that could compromise safety makes these systems essential in the industry.

4. Metal Fabrication

AI-powered AOI systems inspect metal parts, sheets, and tubes for defects such as dents, corrosion, scratches, and cracks. The system can detect these flaws in real-time, ensuring that defective parts are removed from the production line before further processing.

5. Medical Devices

In the medical device industry, precision is critical. AOI systems inspect devices for defects, ensuring compliance with strict regulatory standards. The use of AI enables the system to detect even the smallest flaws that could impact device performance.

.png)

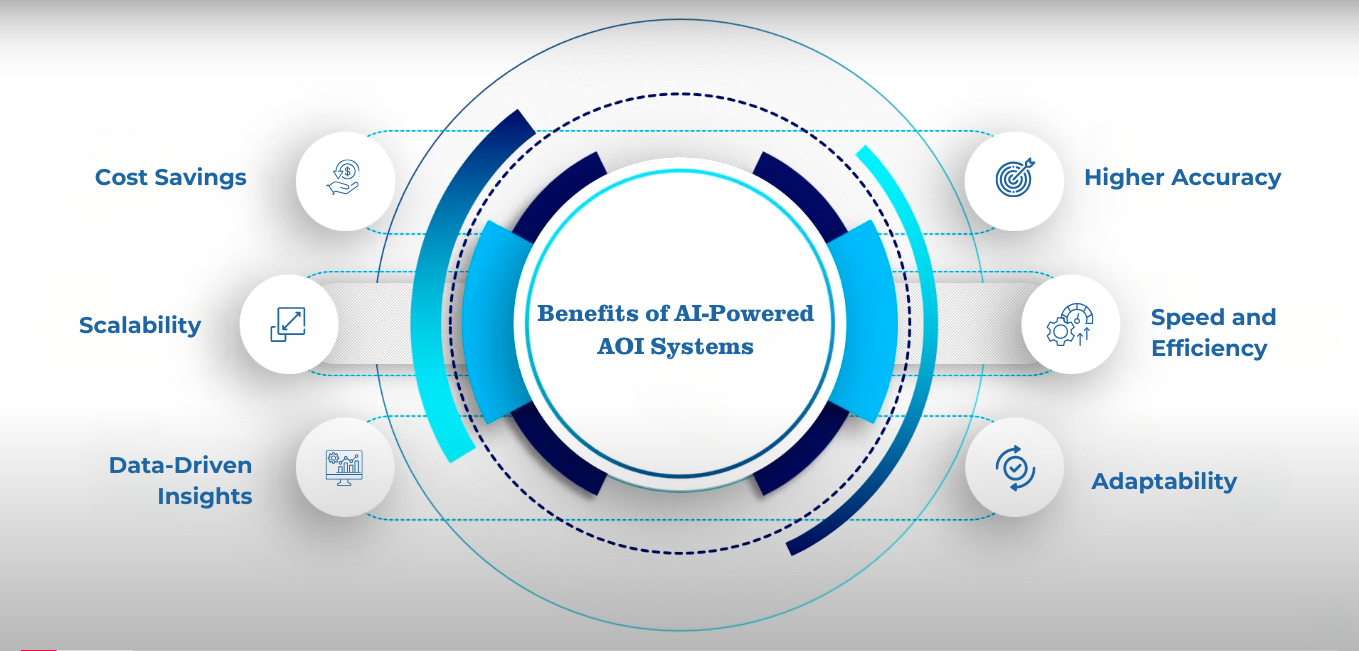

Benefits of AI-Powered AOI Systems for Part Inspection

AI-powered AOI systems bring numerous benefits to manufacturers, including:

- Higher Accuracy: AI models can detect even the most subtle defects with greater precision than human inspectors or traditional AOI systems.

- Speed and Efficiency: Automated systems can inspect parts at high speeds, ensuring that production lines keep running smoothly without sacrificing quality.

- Adaptability: AI models learn from new data, allowing the system to adapt to new parts, materials, or defect types without extensive reprogramming.

- Cost Savings: By reducing the number of defective parts and minimizing rework, AI-powered AOI systems help manufacturers save on materials, labor, and time.

- Scalability: These systems can be scaled to handle high-volume production lines or customized for specific part inspection needs, making them versatile for different industries.

- Data-Driven Insights: The system collects valuable data on defect trends, enabling manufacturers to optimize processes and improve product quality over time.

Intelgic’s Expertise in Designing Customized AOI Systems for Complex Part Inspection

When it comes to complex part inspection, traditional AOI systems often fall short due to the intricacies of inspecting parts with multiple surfaces, irregular shapes, and tiny components like threading holes. These challenges make it difficult to detect defects across all dimensions, especially when parts include fine details that require micron-level accuracy. Intelgic’s AI-powered AOI systems stand out by addressing these challenges through customized solutions that integrate advanced mechanical, electrical, and optical systems tailored for complex part inspection.

Challenges in Complex Part Inspection

Complex parts, such as those used in the automotive, aerospace, and medical device industries, often feature intricate designs with multiple surfaces, curved geometries, and small components. Defects in these parts—such as micro-cracks, uneven surfaces, or incorrect threading—can have a significant impact on product performance and safety. Inspecting these parts for defects requires precision, adaptability, and specialized technology that can handle a variety of inspection criteria simultaneously.

Intelgic’s Customized AOI Systems

Intelgic excels in designing and developing fully customized Automated Optical Inspection (AOI) systems specifically for complex parts. Intelgic’s expertise lies in creating bespoke mechanical, electrical, and optical solutions that work together seamlessly to inspect parts from all angles and detect even the smallest defects. Here’s how Intelgic’s customized AOI systems stand out:

- Customized Optical System for Micron-Level Detection

- Intelgic designs custom imaging solutions that can capture highly detailed images of complex parts, ensuring that even micron-level defects are detected. These optical systems are engineered to provide the resolution and focus needed to highlight surface inconsistencies, thread misalignments, or micro-cracks in small components. Intelgic’s tailored optical solutions ensure that every part, no matter how intricate, is thoroughly inspected.

- Tailored Mechanical Design

- For complex part inspection, Intelgic develops customized mechanical systems that position parts in the most optimal way for inspection. This could involve rotating parts, moving them through multiple axes, or integrating robotics to ensure that all surfaces and angles are covered. By designing mechanical systems that are perfectly aligned with the specific geometry and inspection needs of the part, Intelgic ensures that no surface or component goes unchecked.

- Advanced Electrical Integration

- Intelgic’s AOI systems are integrated with customized electrical components that enable smooth communication between the imaging system, AI processing units, and production line controls. This seamless electrical integration allows for real-time defect detection and decision-making. The electrical system is designed to synchronize the high-speed cameras, lighting solutions, and AI algorithms for efficient and accurate inspection processes.

- Imaging and Lighting Solutions for Complex Geometries

- Complex parts often have reflective surfaces, irregular contours, or hidden features. Intelgic uses customized lighting and structured illumination systems to minimize shadows, reflections, and other factors that could obscure defects. By providing precise lighting angles and intensities, Intelgic ensures that every part is illuminated in a way that reveals critical defects without distortion.

- AI-Powered Defect Detection

- The AI engine behind Intelgic’s AOI systems is highly adaptable, capable of learning to detect a wide range of defects unique to complex parts. From threading inconsistencies in small holes to detecting surface scratches on curved surfaces, Intelgic’s AI algorithms are trained on diverse datasets to ensure high accuracy and minimal false positives.

Why Intelgic’s Customized AOI System Stands Out

- Tailored to the Specific Needs of Complex Parts: Intelgic’s ability to customize the optical, mechanical, and electrical components of its AOI systems ensures that the system is perfectly suited to the unique challenges posed by complex parts.

- High-Resolution Imaging for Micron-Level Defects: With Intelgic’s specialized imaging and lighting systems, manufacturers can detect even the smallest defects that could compromise product quality or safety.

- Seamless Integration: Intelgic’s customized AOI systems are designed to integrate seamlessly into existing production lines, providing real-time feedback and enhancing overall inspection efficiency.

- Precision and Accuracy: By combining AI-powered defect detection with custom-built hardware, Intelgic’s systems ensure that every part is inspected with precision, regardless of its complexity.

Intelgic’s expertise in designing and developing customized AOI systems makes them a trusted partner for manufacturers dealing with complex part inspection challenges. Whether it’s the intricate threading of an automotive component or the fine surface finish of a medical device, Intelgic’s AI-powered AOI system delivers the accuracy, flexibility, and reliability required to maintain the highest standards of quality control.

AI-powered AOI systems, combined with machine vision technology, are transforming part inspection in modern manufacturing. With their ability to deliver real-time, high-precision defect detection and the flexibility to adapt to different production environments, these systems provide manufacturers with a powerful tool for ensuring product quality, reducing costs, and improving operational efficiency.

Whether in the automotive, electronics, aerospace, or medical device industries, the implementation of AI-powered AOI systems enables manufacturers to maintain stringent quality standards and stay competitive in today’s demanding market. As AI and machine vision technologies continue to evolve, these systems will only become smarter and more capable, further enhancing the way manufacturers ensure the integrity of their products.