How to read labels on products using camera and computer vision

Published on: Oct 17, 2024

Written by: Soumen das

How to Read Labels on Products Using Camera and Vision Systems

In today's fast-paced manufacturing and retail environments, automation has become crucial for improving efficiency and ensuring accuracy. One common application of automation is reading product labels, which contain important information such as barcodes, QR codes, expiration dates, batch numbers, and other textual or numeric data. Automating label reading using camera and machine vision systems can help streamline production, enhance traceability, and reduce human error.

Why Automate Label Reading?

Product labels play an essential role in manufacturing, logistics, and retail, providing critical information for inventory tracking, compliance, and consumer safety. Traditional manual methods of reading and verifying labels are prone to error and can slow down operations. Automating this process with vision systems offers several key advantages:

- Increased Speed: Automated systems can read labels in real time, even on fast-moving production lines, without slowing down the process.

- Improved Accuracy: Machine vision systems can accurately read small, intricate, or densely packed labels, reducing the risk of misreads or omissions.

- Consistency: Unlike human operators, vision systems can maintain consistent performance over long periods, ensuring that every label is read and recorded correctly.

- Enhanced Traceability: Automated label reading helps improve traceability throughout the supply chain by ensuring that every product is correctly identified and tracked.

.png)

Components of an Automated Label Reading System

An automated label reading system typically consists of several key components, each playing a vital role in the label reading process:

- Cameras: Capture images of the product labels.

- Lighting: Provides uniform illumination to ensure high-quality images.

- Image Sensors: Convert optical signals from the camera into digital data for analysis.

- Image Processing Software: Analyzes the captured image and extracts relevant information such as text, barcodes, and codes.

- Optical Character Recognition (OCR): A specialized software algorithm used to read and interpret textual information on labels.

- Barcode Readers: Recognize and decode 1D and 2D barcodes printed on labels.

- Software Algorithms: Handle various aspects of label reading, including alignment, verification, and validation.

Types of Labels Commonly Read by Vision Systems

Vision systems are capable of reading a variety of label types, each serving different functions across industries. The most common labels include:

Text Labels

Text labels may include information such as product names, ingredients, manufacturing dates, or expiration dates. These are typically read using Optical Character Recognition (OCR) software.

Challenges:

- Variability in font size, style, and color can make it difficult for OCR systems to interpret text accurately.

- Printed text may be smudged or partially obscured due to the manufacturing process or environmental factors.

Solutions:

- High-Resolution Cameras: To capture small fonts and fine print clearly.

- Preprocessing Filters: Image processing techniques like thresholding, noise reduction, and contrast adjustment can improve the clarity of the text before OCR is applied.

- Trained OCR Algorithms: Machine learning models can be trained to recognize different fonts, styles, and languages used on labels.

Barcodes (1D)

1D barcodes are linear patterns consisting of parallel black and white stripes. They are commonly used to represent product IDs, SKUs, and other codes.

Challenges:

- Barcodes may be damaged, wrinkled, or poorly printed, making them difficult to scan.

- Some products may have their barcodes partially covered by packaging materials.

Solutions:

- Barcode-Specific Cameras: Certain cameras are optimized for barcode reading, providing faster and more accurate scans even for damaged or misprinted barcodes.

- Redundant Scanning: Scanning the barcode from multiple angles can reduce the chances of misreads caused by partial obstructions.

QR Codes (2D Barcodes)

QR codes are 2D matrix codes that store information such as URLs, product details, and manufacturing data. They are becoming increasingly popular due to their ability to store more information than 1D barcodes.

Challenges:

- Distortion or warping of the QR code, especially when applied to curved surfaces, can make them difficult to scan.

- Poor contrast between the QR code and the background can cause errors.

Solutions:

- High-Resolution Cameras: Capable of capturing detailed images of QR codes even on curved or irregular surfaces.

- Lighting Optimization: Proper lighting ensures that the code is well-lit and offers enough contrast for accurate scanning.

4. Expiration Dates and Batch Numbers

Product expiration dates and batch numbers are often printed using inkjet or laser printing technology. Reading these in real-time is critical for industries like pharmaceuticals, food processing, and consumer goods.

Challenges:

- Low-quality or faded printing can make it difficult for cameras to capture these numbers.

- Irregular placement on the product surface can lead to missed reads.

Solutions:

- OCR and Validation Software: OCR algorithms can be trained to specifically identify and validate expiration dates and batch numbers based on predefined formats.

- Variable Position Detection: Advanced image processing algorithms can identify and adjust for variations in label positioning, ensuring that critical information is not missed.

Cameras and Image Sensors for Label Reading

The choice of camera and image sensor in an automated label reading system depends on the type of labels being read, the production speed, and the environmental conditions.

Area-Scan Cameras

Area-scan cameras capture an entire image at once, making them ideal for reading both static and moving products. They are widely used in label reading applications due to their versatility and high resolution.

Key Features:

- High Resolution: Can capture detailed images of labels with small text or intricate patterns.

- Adaptability: Suitable for reading labels on both flat and curved surfaces.

Line-Scan Cameras

Line-scan cameras are designed for high-speed production lines where products move rapidly. These cameras capture images one line at a time as the product passes by, making them ideal for continuous inspections.

Key Features:

- High Speed: Capable of reading labels on products moving at high velocities.

- Large Field of View: Suitable for inspecting wide labels or multiple products simultaneously.

.png)

Lighting Systems for Label Reading

Lighting plays a crucial role in capturing high-quality images for label reading. Without proper illumination, labels may appear blurred, poorly contrasted, or obscured by glare, leading to misreads. Different lighting techniques can be used to optimize label reading performance.

Brightfield Lighting

Brightfield lighting is the most common lighting setup used in machine vision systems. It illuminates the label directly from the front, highlighting contrasts between the printed text or barcodes and the background.

Applications:

- Ideal for reading high-contrast text and barcodes on flat surfaces.

Darkfield Lighting

Darkfield lighting is useful for detecting embossed or raised labels and surface irregularities. It positions the light at an angle, highlighting surface features by reflecting light off the edges of raised text or patterns.

Applications:

- Useful for reading engraved or stamped labels.

Coaxial Lighting

Coaxial lighting minimizes glare when inspecting highly reflective surfaces, such as glossy product packaging. This lighting method uses a beamsplitter to direct light onto the surface and capture reflections directly into the camera lens.

Applications:

- Ideal for reading labels on shiny or metallic packaging.

Backlighting

Backlighting is used to create a high-contrast silhouette of the product, making it ideal for inspecting transparent or translucent labels, or verifying the presence of a label on a product.

Applications:

- Detecting the absence or presence of a label, or reading transparent labels.

.png)

Software for Reading Labels Using Machine Vision

Once an image of the label is captured, software tools and algorithms analyze and extract the required information. Some of the most important software components include:

Optical Character Recognition (OCR)

OCR is the most widely used tool for reading and interpreting printed text on labels. OCR software converts text images into machine-encoded text that can be used for further processing, logging, or tracking.

Features:

- Character Training: OCR systems can be trained to recognize specific fonts, styles, and character sets to improve accuracy.

- Preprocessing: Filters can be applied to the image to enhance contrast, remove noise, and correct for skew, improving OCR performance.

Barcode Decoding Software

Barcode decoding software is specifically designed to recognize and interpret 1D and 2D barcodes. Modern barcode readers are equipped with advanced algorithms that can handle poorly printed or damaged barcodes.

Features:

- Redundancy Checks: Multiple scans of the barcode from different angles improve the accuracy of the read.

- Error Correction: Advanced barcode decoding software includes error correction algorithms to reconstruct damaged or partially missing barcodes.

Pattern Recognition

Pattern recognition software is used to identify specific label patterns, logos, or designs. This is especially useful in cases where labels include company logos or unique symbols that need to be verified as part of the quality control process.

Features:

- Template Matching: The system compares captured label images to pre-defined templates to verify the correct placement, size, and content of logos and symbols.

- Adaptive Learning: Machine learning models can be trained to recognize and verify complex label designs and detect any deviations from the standard.

Real-Time Image Processing

Real-time image processing ensures that label reading happens instantaneously as products move along the production line. This software component is essential for high-speed environments, as it processes and analyzes images in milliseconds.

Features:

- High-Speed Processing: Optimized algorithms ensure that label information is captured and analyzed without slowing down the production line.

- Real-Time Feedback: Automated systems can provide instant feedback to production line controllers, triggering alarms or corrective actions when a label fails to meet standards.

Live Vision: A complete software for real time label reading in manufacturing lines.

Intelgic's Live Vision software is equipped with advanced OCR technology and powerful image processing capabilities, making it an ideal solution for reading labels, barcodes, and QR codes in real-time. The software can accurately interpret text, 1D barcodes, and 2D QR codes on fast-moving products, even in challenging conditions such as low contrast, distortion, or poor print quality. By integrating these label reading capabilities with high-speed cameras and optimized algorithms, Live Vision ensures seamless, accurate label inspection and data extraction for enhanced traceability and quality control across manufacturing and logistics environments.

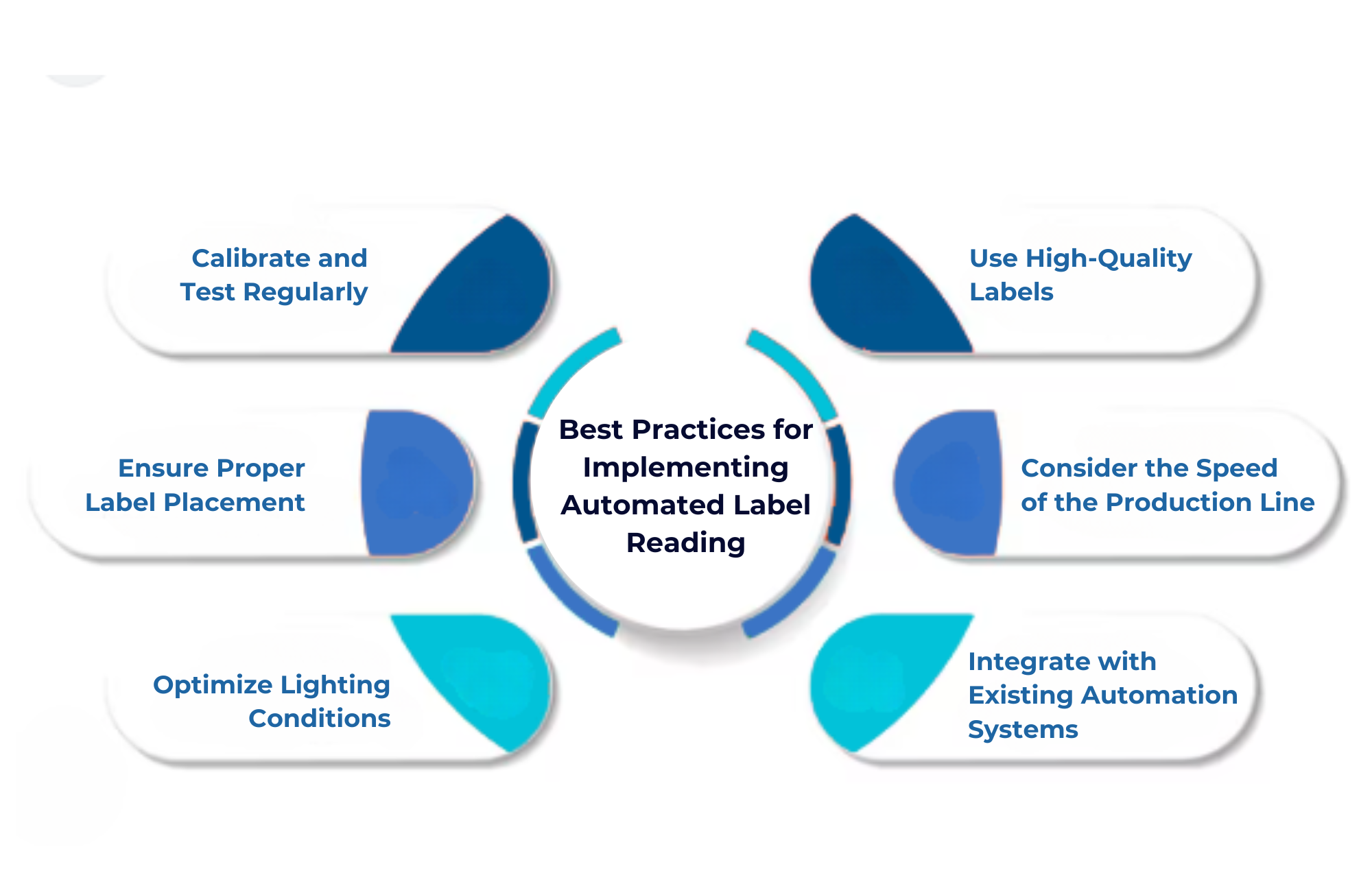

Best Practices for Implementing Automated Label Reading

Implementing an effective machine vision system for reading labels requires careful planning and consideration of the unique challenges associated with different products and production environments. Below are some best practices for achieving optimal performance.

Calibrate and Test Regularly

Regular calibration of cameras, sensors, and lighting systems ensures that the label reading system continues to perform accurately over time. Testing the system regularly, especially after production line changes, helps identify potential issues before they impact performance.

Ensure Proper Label Placement

To ensure accurate label reading, labels must be consistently placed on the product in a predictable and repeatable manner. Irregular placement or skewed labels can make it difficult for the vision system to capture the information correctly.

Solution:

- Guides and Fixtures: Use mechanical guides or fixtures on the production line to ensure that labels are applied uniformly.

- Software Adjustments: Advanced machine vision systems can correct for slight variations in label placement by adjusting the image capture or processing parameters.

Optimize Lighting Conditions

Choosing the right lighting setup is crucial for capturing high-quality images of the labels. Proper lighting ensures that text, barcodes, or QR codes are clearly visible, reducing the chances of misreads due to poor contrast or glare.

Solution:

- Adjustable Lighting: Use lighting systems with adjustable intensity or direction to adapt to different label types or surface conditions.

- Polarizing Filters: For highly reflective surfaces, polarizing filters can be used to minimize glare and improve image clarity.

Use High-Quality Labels

The quality of the labels themselves can have a significant impact on the performance of automated label reading systems. Low-quality printing, smudged ink, or poorly applied labels can make it difficult for cameras and software to read the information accurately.

Solution:

- Use Durable Labels: Opt for high-quality, durable labels that can withstand handling, packaging, and environmental conditions during production.

- Verify Printing Quality: Ensure that text and barcodes are printed clearly and consistently to avoid issues with label readability.

Consider the Speed of the Production Line

The speed at which products move along the production line can affect the performance of the label reading system. High-speed lines require faster cameras, sensors, and processing algorithms to keep up with the pace.

Solution:

- Choose High-Speed Cameras: Ensure that the cameras used in the system are capable of capturing images at the necessary frame rates for the speed of your production line.

- Parallel Processing: Implement parallel processing techniques to handle large volumes of data quickly and efficiently.

Integrate with Existing Automation Systems

The label reading system should be seamlessly integrated with other automation systems on the production line, including robotic arms, packaging machines, and inventory management software. This ensures that the data captured from labels is automatically processed and logged for inventory, compliance, and traceability purposes.

Solution:

- Communication Protocols: Use standardized communication protocols such as OPC UA, Modbus, or Ethernet/IP to connect the label reading system to the broader automation infrastructure.

- Real-Time Data Logging: Ensure that the system is capable of logging label information in real-time, providing a clear audit trail for compliance and traceability.

Applications of Automated Label Reading Systems

Automated label reading systems are used in a wide range of industries to improve accuracy, efficiency, and traceability. Some key applications include:

Pharmaceutical and Medical Devices

In the pharmaceutical industry, accurate label reading is essential for ensuring that the correct drugs are labeled, tracked, and delivered to patients. Labeling errors can lead to dangerous consequences, making automated label reading crucial for safety and compliance.

Applications:

- Verifying expiration dates, batch numbers, and barcodes on pharmaceutical packaging.

- Reading and validating labels on medical devices for regulatory compliance.

Food and Beverage

In food and beverage manufacturing, labels contain critical information such as expiration dates, ingredient lists, and nutritional information. Automated systems ensure that labels are applied correctly and that the information is accurately captured for inventory tracking and traceability.

Applications:

- Scanning and verifying expiration dates and batch numbers on perishable goods.

- Reading labels on beverage containers to ensure that packaging and product match.

Automotive and Electronics

In the automotive and electronics industries, labels are often used for tracking parts, components, and assembly sequences. Accurate label reading is essential for ensuring that the correct parts are used in the right processes, and for tracing defects back to their source.

Applications:

- Reading and verifying barcodes on automotive parts to track assembly processes.

- Identifying and reading QR codes on electronic components for quality control and inventory management.

Retail and Consumer Goods

In retail, labels are essential for pricing, inventory management, and product identification. Automated label reading systems ensure that products are correctly labeled, priced, and scanned during packaging and shipping.

Applications:

- Scanning barcodes and QR codes on consumer goods to ensure that the correct prices are applied.

- Verifying that the right labels are applied to products before they are shipped to stores.

Automated label reading systems are an integral part of modern manufacturing and logistics, providing the speed, accuracy, and consistency needed to handle today’s high-volume production lines. By leveraging high-resolution cameras, advanced image sensors, optimized lighting, and powerful software, manufacturers can ensure that product labels are read and processed efficiently, reducing errors and improving traceability.

As technology continues to evolve, machine vision systems for label reading will become even more capable, with the integration of AI, machine learning, and edge computing further enhancing their ability to adapt to complex and dynamic production environments. By implementing the right components and following best practices, manufacturers can ensure that their automated label reading systems deliver reliable, high-performance results in any industry.