Machine Vision Inspection

Published Jun 16, 2024

Machine vision inspection is a technology in modern manufacturing, ensuring product quality and consistency. It automates the process of examining products for defects and discrepancies, playing a vital role in maintaining high standards in production lines. This article explores what machine vision inspection is, how it works, the traditional approaches, the emergence of AI-driven systems, and the advantages of AI-powered machine vision inspection.

What is Machine Vision Inspection?

Machine vision inspection is the process of using computer vision and image processing technologies to automatically inspect products and components during manufacturing. It involves capturing images or videos of products as they move along the production line and analyzing these visual data to identify defects, measure dimensions, verify assembly, and more.

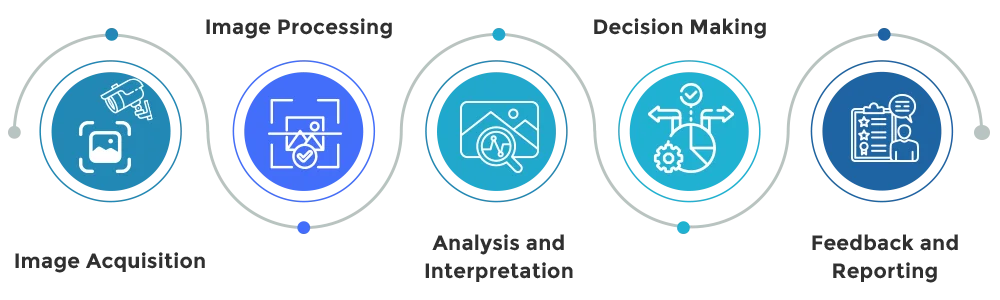

How Does Machine Vision Inspection System Work?

- Image Acquisition:Cameras or sensors capture images or video streams of the products. These images can be taken under various lighting conditions and from multiple angles to ensure comprehensive inspection.

- Image Processing: The captured images are processed using software algorithms to enhance quality, filter out noise, and highlight relevant features. Techniques like edge detection, thresholding, and morphological operations are commonly used.

- Analysis and Interpretation: The processed images are analyzed to detect defects, measure dimensions, or verify the presence and alignment of components. This is done by comparing the images to predefined standards or reference models.

- Decision Making: Based on the analysis, the system makes decisions about the inspected products. Products that meet the standards are allowed to proceed, while those with defects are flagged for rejection or rework.

- Feedback and Reporting: The system provides real-time feedback to the production line and generates reports on inspection results, helping in process improvement and quality control.

Traditional Approach to Machine Vision Inspection

Traditional machine vision inspection systems rely on rule-based algorithms and predefined criteria to identify defects. These systems involve significant manual setup and programming to define the parameters and standards for inspection. Key characteristics of traditional systems include

- Fixed Rules and Parameters: Specific rules and thresholds are set for defect detection, which may not adapt well to variations in product appearance or new defect types.

- High Cost and Complexity: Traditional systems can be expensive to set up and maintain, requiring specialized hardware and software.

- Limited Scalability: Each production line or inspection point often requires a separate system, making it challenging to scale up operations.

AI-Driven Machine Vision Inspection

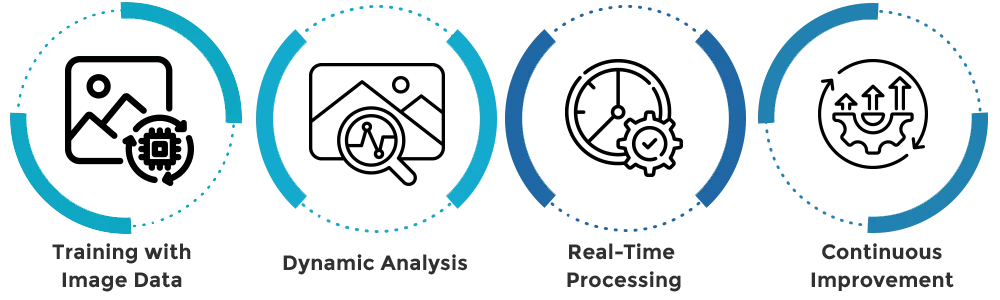

AI-driven machine vision inspection systems leverage artificial intelligence, particularly deep learning, to enhance the capabilities of traditional systems. These systems are more adaptable, accurate, and scalable. Here’s how AI-driven inspection works:

- Training with Image Data: AI models, especially Convolutional Neural Networks (CNNs), are trained on large datasets of images to learn to identify defects. These datasets include examples of both defective and non-defective products.

- Dynamic Analysis: Unlike fixed-rule systems, AI models can dynamically analyze images and adapt to new types of defects or variations in product appearance without extensive reprogramming.

- Real-Time Processing: AI-driven systems can process images in real-time, making them suitable for high-speed production lines.

- Continuous Improvement: The models can continuously improve their accuracy by learning from new data, making the inspection process more robust over time.

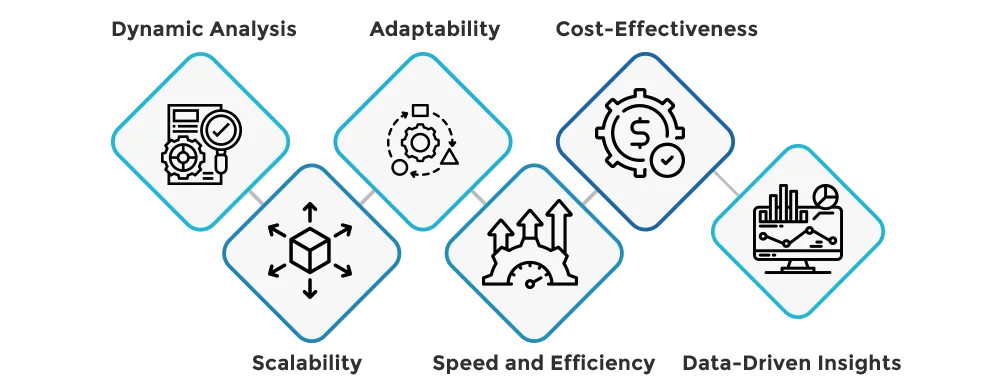

Advantages of AI-Powered Machine Vision Inspection Systems

- Higher Accuracy: AI models can detect subtle and complex defects that traditional systems might miss, ensuring higher quality products.

- Scalability: A single AI system can handle multiple inspection points or production lines, reducing the need for multiple separate systems and lowering costs.

- Adaptability: AI systems can easily adapt to different products and defect types without extensive reprogramming, making them versatile across various manufacturing scenarios.

- Speed and Efficiency: AI-driven systems can process and analyze images quickly, keeping up with fast production lines and reducing downtime.

- Cost-Effectiveness: Despite the initial investment, AI systems can lead to long-term cost savings by reducing manual labor, minimizing defects, and improving overall efficiency.

- Data-Driven Insights: AI systems generate detailed reports and analytics, providing valuable insights for continuous process improvement and quality control.

Machine vision inspection is a cornerstone of modern manufacturing, ensuring product quality and consistency. While traditional systems have laid the foundation, AI-driven machine vision inspection is revolutionizing the field with its accuracy, scalability, and adaptability. By embracing AI-powered systems, manufacturers can achieve higher standards of quality, improve operational efficiency, and remain competitive in an increasingly demanding market.