What is Coaxial Light and Where Should We Use It in Visual Inspection

Published on: Jun 05, 2025

Written by: Content team, Intelgic

What is Coaxial Light?

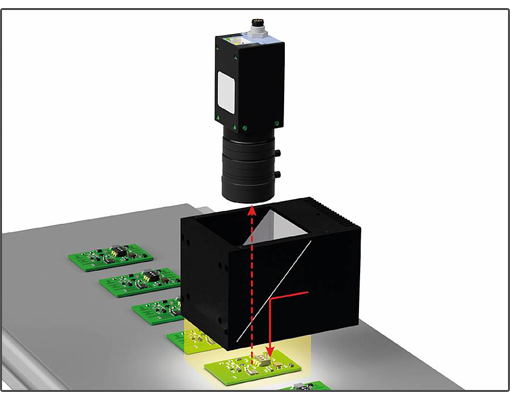

Coaxial light is a specialized lighting technique in which the light source is precisely aligned along the same optical axis as the camera lens. The light travels directly through a beam splitter or a partially reflective mirror, illuminating the object from the exact viewpoint of the camera. This unique alignment creates highly controlled, uniform, and glare-free illumination—making coaxial lighting especially effective for inspecting flat and highly reflective surfaces such as aluminum sheets, glass panels, and polished metals.

Where should we use Coaxial Light in AI-Powered Inspection?

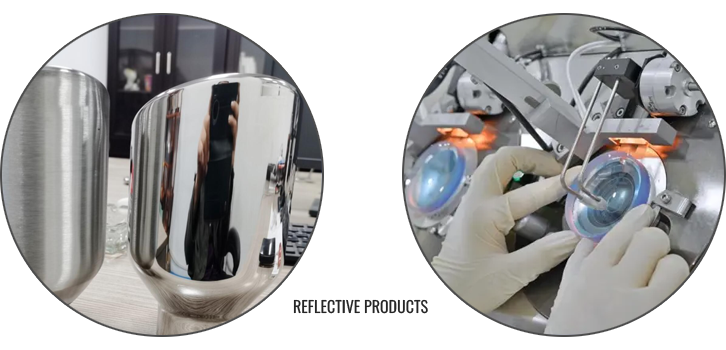

Coaxial lighting has become an indispensable technology for the surface inspection of reflective products, where traditional lighting methods often fail to deliver clear and accurate results. Reflective materials—such as polished metals, glass, and coated surfaces—pose unique challenges due to their tendency to produce glare and distracting reflections that can mask defects.

By directing light precisely along the same optical axis as the camera, coaxial lighting provides several key advantages:

- Glare Reduction: Minimizes surface reflections and glare, enabling clearer visibility of defects.

- Uniform Illumination: Delivers consistent, shadow-free light across the inspection area, improving image quality.

- Enhanced Defect Detection: Highlights subtle surface imperfections such as scratches, stains, cracks, and coating irregularities that may be invisible under conventional lighting.

- Improved Image Contrast: Creates high-contrast images that are ideal for advanced AI-powered inspection algorithms, enhancing defect recognition accuracy.

Applications Across Various Industries

Coaxial lighting, when integrated with AI-powered visual inspection systems, plays a vital role in ensuring quality and precision across a wide range of industries—especially where reflective surfaces are involved. Below are some key application areas:

- Electronics:

In the electronics industry, coaxial lighting is used to inspect PCB surfaces, glass display panels, and semiconductor wafers. Its ability to eliminate glare and provide uniform lighting is crucial for detecting minute defects such as scratches, micro-cracks, solder inconsistencies, and alignment errors—elements that are often invisible under conventional lighting.

- Automotive:

Surface quality checks on painted panels, chrome trims, and glass components greatly benefit from this glare-free lighting. It allows manufacturers to catch imperfections such as dust particles, paint bubbles, and finish inconsistencies early, ensuring both visual excellence and safety compliance.

- Pharmaceuticals:

In pharmaceutical packaging inspection, coaxial lighting is ideal for verifying the integrity of reflective surfaces like blister packs, foil seals, and ampoules. Its glare-free illumination helps detect sealing defects, label misalignment, and foreign particles that could compromise product safety or regulatory compliance.

- Metalworking:

In metal fabrication, where polished and coated components require flawless surfaces, this method reveals subtle anomalies including dents, scratches, and coating defects that can affect performance and appearance.

- Consumer Goods:

For consumer products, especially those with glossy finishes or reflective packaging, coaxial lighting ensures that the visual appeal and brand presentation remain flawless. It helps detect scuffs, surface smudges, or printing defects on items like cosmetic packaging, electronics casings, and luxury goods.

Intelgic’s Expertise in Coaxial Light Inspection

Intelgic leverages advanced coaxial lighting technology to achieve exceptional accuracy in surface inspection—particularly for reflective and complex materials. Each lighting setup is precisely engineered to match the optical and structural characteristics of the target surface, ensuring optimal illumination conditions and crystal-clear imaging.

This highly controlled, on-axis lighting eliminates glare and uneven reflections, allowing even the most subtle surface flaws to be identified with clarity. When combined with Intelgic’s AI-driven inspection algorithms, the result is an intelligent system capable of enhancing defect classification, minimizing false positives, and enabling fast, reliable decision-making on the production line.

By integrating coaxial illumination into its inspection solutions, Intelgic helps manufacturers streamline quality control, reduce downtime, and maintain uncompromised product standards—empowering industries to operate with greater precision, consistency, and confidence.

Discover the future of flawless inspection — connect with Intelgic today.