Surface Defect Detection of Aluminium Sheets Using Machine Vision AI

Published on: Jun 04, 2025

Written by: Content team, Intelgic

Surface Defect Detection of Aluminium Sheets Using Machine Vision AI

Aluminium sheets play a crucial role in a wide range of industries, prized for their exceptional combination of lightweight properties, corrosion resistance, and structural strength. From automotive panels to aerospace components and architectural cladding, these sheets must meet high standards of surface quality and integrity. However, during the manufacturing process, handling, or subsequent storage, various surface defects can arise—such as scratches, dents, or oxidation—that may compromise not only the visual appeal but also the functional performance and safety of the final product. Detecting these imperfections with high accuracy is essential, yet traditional manual inspection methods are often inconsistent and limited by human fatigue and subjective judgment. This is where Machine Vision AI becomes invaluable. By leveraging advanced imaging technology and intelligent algorithms, automated inspection systems can detect even the most subtle defects with remarkable speed, precision, and reliability—ensuring consistent quality control at scale and reducing reliance on human intervention.

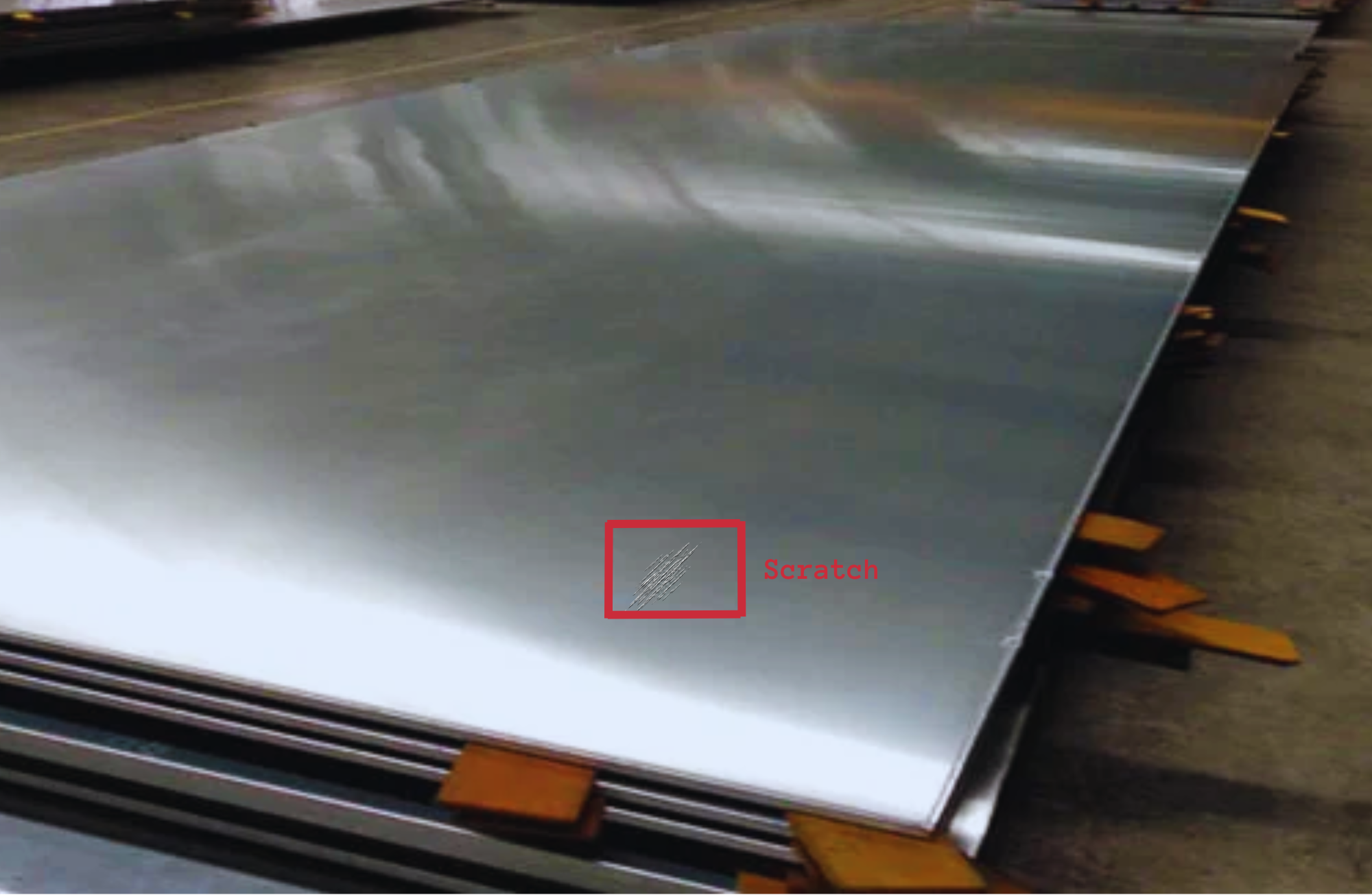

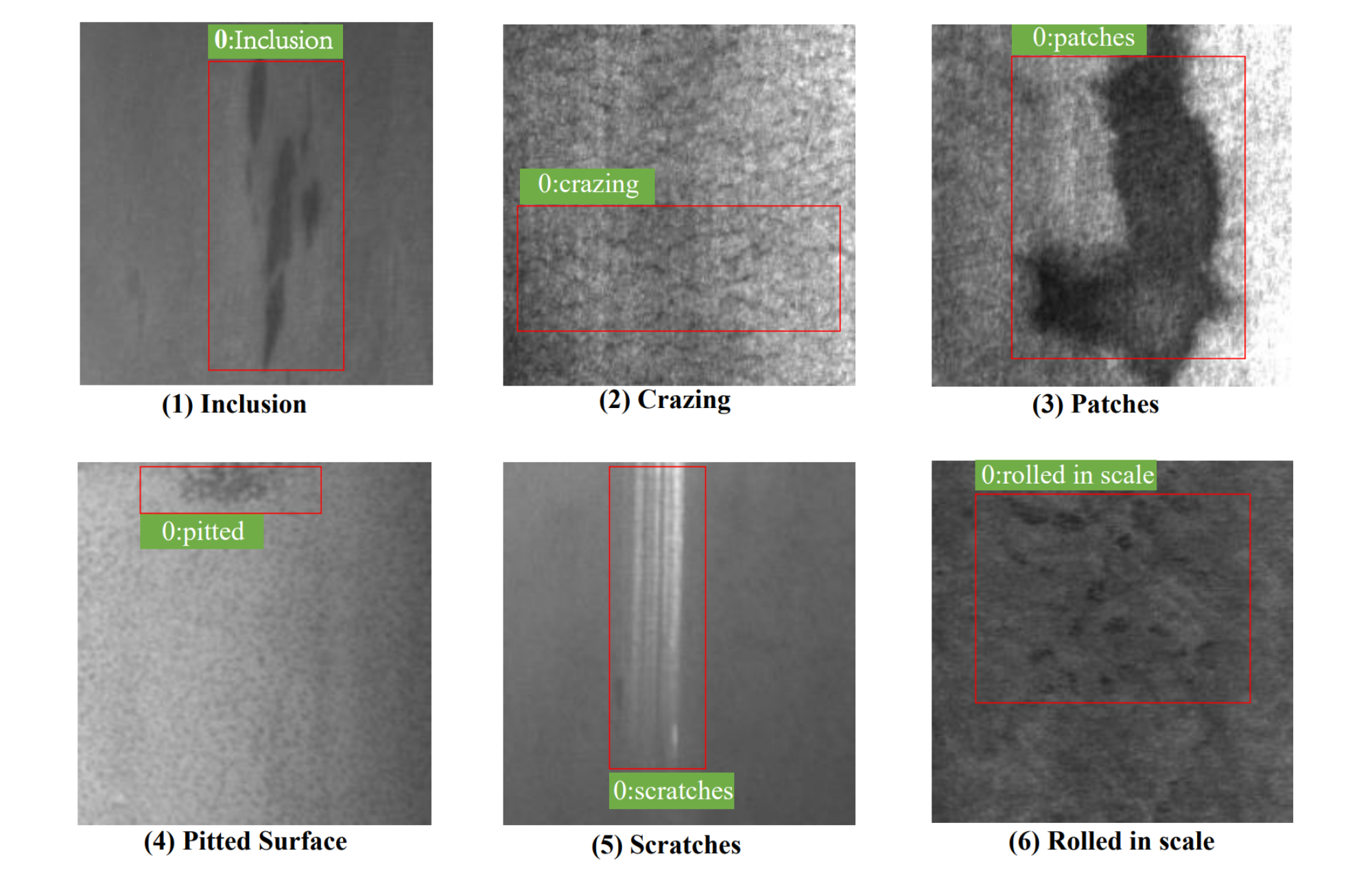

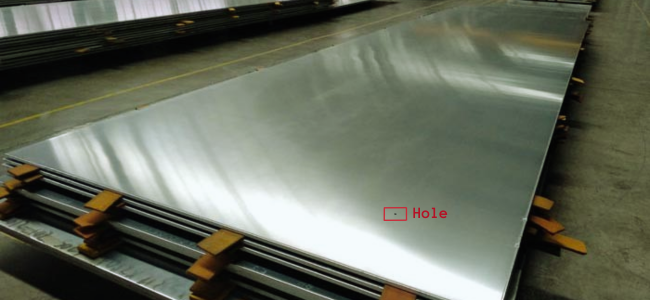

Common Defects in Aluminium Sheets

Defects in aluminium sheets vary depending on the production process and the intended application. These defects can affect both the surface quality and structural integrity of the material. Common anomalies include:

- Scratches and Abrasions

- Often caused by rough handling, contact with sharp objects, or abrasive surfaces during processing or transportation.

- Dents and Dimples

- Result from mechanical impact or pressure, which can distort the sheet’s surface and compromise uniformity.

- Roll Marks and Waviness

- Typically arise from inconsistencies in the rolling process, leading to visible lines or uneven surface texture.

- Pits and Pinholes

- Small cavities or holes caused by trapped gas bubbles or contamination during casting or rolling.

- Oxidation Spots and Discoloration

- Occur due to exposure to moisture, humidity, or chemicals, leading to visual defects and potential corrosion.

- Inclusions and Foreign Material Particles

- Non-metallic or metallic particles embedded in the sheet, often originating from the production environment or raw material impurities.

- Cracks or Fractures

- Critical defects that may develop due to internal stress, improper rolling, or cooling, potentially affecting structural strength.

- Critical defects that may develop due to internal stress, improper rolling, or cooling, potentially affecting structural strength.

Challenges in Aluminium Sheet Inspection

Reflectivity: Aluminium’s high reflectivity can distort captured images, making defect detection difficult.

High Speed & Volume: Aluminium sheets often move at high speeds in continuous production lines, making real-time inspection challenging.

Variability in Defect Types: Defects vary in size, shape, contrast, and location.

Large Dimensions: Sheets often exceed 1000 mm in width, requiring specialized imaging systems.

Human Error: Manual inspections are inconsistent, time-consuming, and not scalable.

Role of Machine Vision AI in Overcoming Inspection Challenges

Machine Vision AI uses deep learning and computer vision to accurately detect and classify defects on aluminium sheets, even under challenging conditions. It offers high-speed inspection, reduces false results, scales easily across production lines, and adapts to new defect types with minimal setup. Combined with advanced imaging, specialized illumination for reflective surfaces, and powerful AI software, the system ensures precise and reliable defect detection in real time.

High Accuracy Imaging Solutions:

Line Scan Cameras for Large Aluminium Sheets:

Line scan cameras are ideal for inspecting wide and continuous aluminium sheets. These cameras capture one pixel row at a time at very high speed and resolution—typically scanning sheets as wide as 1000–2000 mm with micron-level defect detection capabilities. Perfectly suited for conveyor lines, line scan systems ensure uninterrupted inspection without image distortion.

Area Scan Cameras for Small Aluminium Sheets:

For smaller sheets or localized inspections, area scan cameras provide high-resolution two-dimensional images in a single frame. They are effective in applications involving batch-based sheet processing, typically used for dimensions up to 500 mm.

Advanced Illumination for Reflective Surfaces

Aluminium’s highly reflective nature complicates traditional lighting methods, but advanced illumination techniques help achieve clear and consistent imaging.These advanced lighting techniques collectively ensure high-contrast, distortion-free images for reliable defect detection on glossy and uneven aluminium sheets.

- Diffuse Dome Lighting:

Provides soft, uniform illumination that minimizes harsh reflections and highlights subtle surface variations.

- Polarized Lighting:

Reduces specular glare by filtering reflected light, enhancing contrast to reveal fine defects.

- Backlighting:

Creates silhouette effects to help detect edge cracks, cuts, and deformations more effectively.

- Structured Light Projection:

Projects patterned light onto the surface for 3D profiling, capturing depth variations and surface irregularities.

AI Software in Defect Detection

Intelgic’s Live Vision AI software enhances aluminium sheet inspection by seamlessly integrating with advanced camera systems, enabling real-time, precise defect detection and comprehensive analysis.

- Real-Time Image Processing and Analysis: The software works in tandem with high-resolution camera systems to capture and analyze images instantly, ensuring immediate identification of defects during the inspection process.

- Accurate Defect Segmentation: It classifies detected defects by specific types and severity levels, allowing manufacturers to prioritize remediation efforts based on criticality.

- Automated Quality Control Alerts: The system proactively flags any deviations from predefined production standards, facilitating strict adherence to quality requirements.

- Comprehensive Reporting: Detailed visual and statistical inspection reports are generated, providing actionable insights that support data-driven decision-making and continuous process improvement.

- Seamless Integration with MES and ERP: Intelgic’s AI software integrates effortlessly with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms, enabling automated feedback loops that optimize production workflows and enhance operational efficiency.

- Advanced Defect Detection Using CNNs: Leveraging convolutional neural networks, the software achieves superior accuracy in detecting subtle and complex anomalies that are often undetectable through traditional inspection methods, thereby significantly improving product quality and reliability.

Step-by-Step Process of the Aluminium Sheet Surface Inspection

- Sheet Movement: Aluminium sheets are transported smoothly along a conveyor or automated handling system, ensuring consistent positioning for inspection.

- Image Acquisition: High-resolution images are captured using either line scan or area scan cameras, enhanced by specialized illumination techniques tailored to minimize reflections and highlight surface features.

- AI Analysis: The captured images are processed in real time by advanced AI software, which applies deep learning algorithms to evaluate the sheet’s surface with precision and speed.

- Defect Detection: The AI system identifies, classifies, and accurately localizes any defects—ranging from minor surface blemishes to critical structural anomalies—enabling targeted quality control.

- Result Generation: Inspection outcomes are immediately displayed on operator interfaces and can be integrated with automation systems to trigger sorting, rejection, or further processing based on defect severity.

- Data Logging: Al inspection data, including images and defect metrics, are securely logged to ensure full traceability, support quality assurance protocols, and facilitate continuous process improvement.

Applications Across Industries

- Automotive: Used in body panels and heat shields to reduce weight and enhance efficiency.

- Aerospace: Essential for aircraft skin and structural parts requiring precision and durability.

- Construction: Applied in facades, roofing, and window frames for long-lasting protection and aesthetics.

- Electronics: Utilized in heat sinks and enclosures for thermal management and shielding.

- Packaging: Foils and laminates protect products with excellent barrier properties while being recyclable.

Advantages of Machine Vision AI in Aluminium Sheet Inspection

- 24/7 Uninterrupted Operation: Capable of continuous, non-stop inspection without fatigue, ensuring consistent quality monitoring across all production shifts.

- Consistent and Objective Evaluation: Provides uniform and unbiased defect detection, eliminating variability caused by human inspection and enhancing overall reliability.

- High Throughput with Real-Time Processing: Processes large volumes of sheets rapidly with instant analysis, supporting fast production lines without compromising accuracy.

- Customizable to Product Types and Line Speeds: Easily adaptable to different aluminium products, thicknesses, and varying conveyor speeds, ensuring optimal performance across diverse manufacturing setups.

- Early Defect Detection Minimizes Waste and Rework: Identifies defects at the earliest stages, reducing material waste, lowering production costs, and preventing downstream rework.

- Full Data Traceability for Quality Compliance: Maintains comprehensive records of inspection results, enabling traceability, regulatory compliance, and facilitating continuous quality improvement initiatives.

Intelgic’s Proven Excellence in Aluminium Sheet Quality Control

Intelgic delivers state-of-the-art surface inspection solutions through its proprietary Machine Vision AI platform, specifically designed for aluminium sheet quality control. With deep expertise in industrial automation, these systems are deployed across global manufacturing lines to detect and classify defects with exceptional accuracy. Whether implementing high-speed line scan cameras for large-format sheets or customizing area scan solutions for smaller components, the focus remains on achieving precision, reliability, and efficiency.

Driven by advanced deep learning models, smart camera integration, and adaptive illumination techniques, the platform ensures intelligent, real-time inspection. Continuous innovation enables manufacturers to maintain top-tier product quality, reduce defect rates, and remain competitive in a rapidly evolving market.

Contact us today to explore how our AI-powered inspection technology can elevate your quality assurance processes.