Revolutionizing Pipe Counting with AI-Powered Machine Vision: Real-Time Accuracy and Operational Efficiency

Published on: Jun 18, 2025

Written by: Team Intelgic

Revolutionizing Pipe Counting with AI-Powered Machine Vision: Real-Time Accuracy and Operational Efficiency

In today’s high-speed industrial environments, precision and efficiency are not just goals—they're necessities. In sectors like pipe manufacturing, warehousing, and logistics, accurate pipe counting is critical to maintaining seamless production, inventory accuracy, and quality assurance.Yet, traditional methods such as manual counting or basic sensor systems often fall short. They introduce costly errors, slow down operations, and increase labor demands—making them unsustainable in modern, high-throughput settings.

AI-powered Machine Vision offers a transformative alternative. By combining advanced imaging technology with intelligent algorithms, this cutting-edge solution delivers real-time, automated pipe counting with exceptional accuracy. It enhances operational visibility, reduces error margins, and enables smarter, faster decision-making—ushering in a new era of efficiency and control across the industrial landscape.

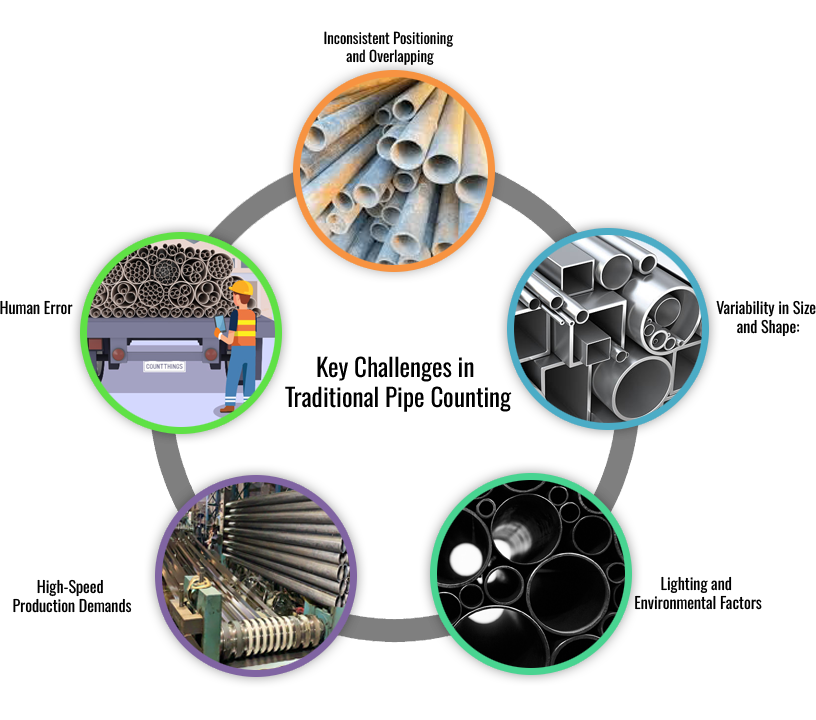

Key Challenges in Traditional Pipe Counting

Pipe counting in dynamic industrial settings presents several persistent challenges:

- Inconsistent Positioning and Overlapping: Pipes are often misaligned or stacked unevenly, making accurate detection difficult using traditional methods.

- Variability in Size and Shape: Differences in pipe diameter, length, or surface characteristics confuse basic mechanical or optical sensors.

- Lighting and Environmental Factors: Reflections, shadows, and inconsistent lighting conditions degrade the reliability of conventional vision systems.

- High-Speed Production Demands: Manual or semi-automated systems cannot consistently keep pace with rapid production lines.

- Human Error: Manual counting is inherently prone to oversight, leading to discrepancies in reporting and inventory tracking.

How AI-Powered Machine Vision Addresses These Challenges

-

AI-driven machine vision systems combine high-resolution imaging, deep learning models, and adaptive lighting to deliver consistent, accurate pipe counting under diverse operational conditions. Key features include:

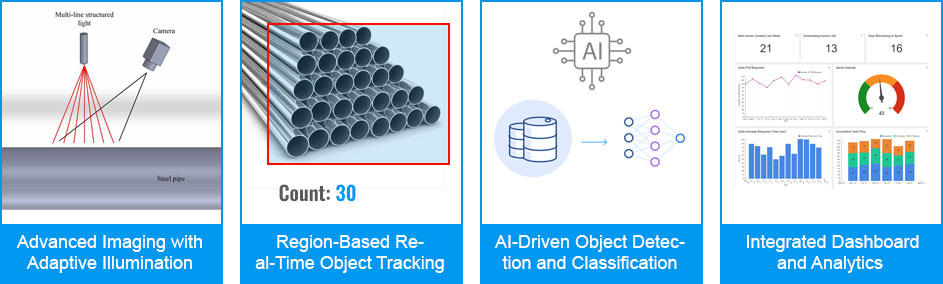

1. Advanced Imaging with Adaptive Illumination

High-resolution industrial grade cameras, integrated with adaptive lighting systems, ensure optimal image clarity in a wide range of environmental conditions. The technology intelligently compensates for visual challenges such as glare, shadows, reflections, and surface irregularities—common in industrial settings. Through real-time adjustments to exposure, contrast, and illumination, the system consistently delivers precise, high-fidelity image capture, enabling accurate detection even in fast-paced or visually complex environments.

2. Region-Based Real-Time Object Tracking

To ensure maximum accuracy in dynamic and cluttered environments, the system leverages a Region of Interest (ROI) approach. Specific zones within the camera’s field of view are carefully configured to focus detection solely where pipe movement occurs. This targeted strategy effectively filters out irrelevant background elements such as machinery, personnel movement, or overlapping objects that could otherwise trigger false counts.

By isolating analysis to these predefined areas, the system minimizes visual noise and maximizes detection precision. This focused method not only improves counting accuracy but also enhances processing efficiency—allowing the system to deliver consistent, real-time results even in visually complex or high-speed operational settings.

3. AI-Driven Object Detection and Classification

AI Software is built on deep learning technology and trained using extensive datasets comprising diverse pipe images captured in real industrial conditions. This includes variations in size, diameter, surface texture, orientation, and visibility. As a result, the AI Software can reliably identify pipes whether they are moving at high speed, partially obscured by other objects, irregularly stacked, or presented at different angles.

Its robust recognition capabilities go far beyond traditional vision systems, which often falter under visual complexity. By learning to interpret subtle visual cues and adapt to dynamic environments, the AI delivers consistent and precise detection across a wide range of operational scenarios. This enables accurate counting in challenging conditions where conventional methods are prone to errors or failure.

4. Integrated Dashboard and Analytics

Real-time data is visualized on a centralized dashboard, providing operators with immediate insight into system performance and throughput. All counting events are logged with corresponding image data, supporting audit trails, compliance verification, and process optimization. Integration with existing MES, ERP, or cloud platforms enables seamless enterprise-wide analytics and reporting.

Machine Vision AI Pipe Counting Workflow

- High-resolution industrial cameras, paired with adaptive illumination modules, are strategically mounted along the pipe movement path—typically above conveyors, racks, or handling zones. These components are precisely aligned to focus on a pre-defined Region of Interest (ROI), ensuring optimal visibility and image capture within the critical inspection area.

- Intelligent Calibration

The system undergoes an initial calibration phase, where the AI is trained to recognize specific attributes of the pipes being processed. This includes variations in shape, diameter, length, surface finish, and material type. Through this configuration, the AI model is optimized to maintain high detection accuracy, even when pipes vary in appearance or orientation.

- Real-Time Detection and Tracking

As pipes pass through the ROI, the AI engine analyzes live video feeds frame-by-frame. Using deep learning and advanced object tracking, it identifies each individual pipe—regardless of whether they are overlapping, partially obscured, or moving at high speed—and updates the count in real time. This ensures consistent performance in both linear and batch flow operations.

- Dynamic Dashboard Visualization

All detection activity is visualized through an intuitive, real-time dashboard. Operators can monitor live count data, system status, and performance metrics at a glance. The dashboard provides clear insights for immediate validation, troubleshooting, and decision-making—helping maintain continuous workflow control.

- Anomaly Alerts and Data Logging

To support traceability and operational integrity, the system automatically detects and flags anomalies such as miscounts, missing units, or foreign object intrusions. All event data, including images and count logs, are securely stored for post-process analysis, compliance reporting, and ongoing system refinement.

Key Advantages of AI-Powered Machine Vision in Pipe Counting

- Exceptional Accuracy

Achieves near-zero error rates by reliably identifying pipes across a wide range of conditions, dramatically reducing inventory discrepancies and enhancing product accountability.

- High-Speed Operation

Capable of real-time counting even in high-velocity production lines, maintaining precision without sacrificing throughput.

- Flexible Adaptability

Automatically adjusts to different pipe sizes, materials, and configurations without requiring manual recalibration—ideal for environments with frequent product changes.

- Reduced Labor Dependence

Eliminates manual counting, reducing labor costs and minimizing the risk of fatigue-related errors.

- Real-Time Operational Insight

Delivers continuous monitoring and actionable insights, empowering teams to quickly identify and resolve anomalies.

- Scalability and System Integration

Easily scalable across multiple lines or facilities, and compatible with enterprise systems for centralized control and reporting.

Applications in Various Industries

AI-powered machine vision pipe counting systems are adaptable across multiple sectors, enhancing accuracy, efficiency, and traceability in operations:

- Pipe & Tube Manufacturing: Ensures real-time, error-free counting on fast production lines.

- Metal Processing: Handles size and surface variations in steel, aluminum, and copper pipes.

- Oil & Gas: Tracks pipes accurately for compliance and safety in storage and distribution.

- Logistics & Warehousing: Verifies bundled or stacked pipes for precise inventory and shipping.

- Construction: Supports material tracking from factory to site for seamless project management.

- Automotive & Aerospace: Counts critical pipe components to prevent assembly errors.

Redefining Pipe Counting: Intelgic’s Innovative Approach

In today’s high-demand industrial environments, accuracy, speed, and automation are non-negotiable. Intelgic is at the forefront of innovation, delivering AI-powered pipe counting solutions that combine advanced machine vision, adaptive imaging, and intelligent analytics. Designed to address the limitations of manual and sensor-based methods, Intelgic’s technology ensures real-time accuracy, operational efficiency, and seamless integration across diverse production landscapes.Here’s how Intelgic is leading the way:

- High-Precision Imaging with Adaptive Lighting

Intelgic’s solution incorporates industrial-grade cameras and intelligent lighting systems that automatically adjust to environmental conditions—ensuring consistent image clarity even in the presence of glare, shadows, or motion blur.

- AI-Driven Object Detection

Leveraging deep learning models trained on extensive datasets, the system accurately identifies and counts pipes of varying shapes, sizes, and orientations, including those that are stacked, partially visible, or moving at high speeds.

- Targeted Region-of-Interest (ROI) Analysis

The system focuses detection within predefined zones to minimize background interference and eliminate false counts, delivering reliable results in visually complex environments.

- Seamless Integration with Enterprise Systems

Intelgic’s platform is designed for easy integration with existing MES, ERP, and cloud infrastructures, supporting real-time data exchange, centralized monitoring, and scalable deployment.

- Real-Time Monitoring and Visualization

A user-friendly dashboard provides live visibility into counting operations, system health, and diagnostics, enabling prompt decision-making and operational transparency.

- Scalability and Customization

The solution is highly adaptable to diverse production environments and can be tailored to meet specific operational needs, making it suitable for both single-line and multi-site implementations.

As industrial operations continue to evolve, the need for precision, automation, and data-driven insights is more critical than ever. Intelgic’s AI-powered machine vision solutions for pipe counting offer a transformative leap in operational accuracy, efficiency, and scalability. From high-speed production lines to complex logistics environments, Intelgic empowers organizations to eliminate manual errors, enhance traceability, and gain real-time visibility across their workflows.

By integrating intelligent imaging, deep learning, and seamless system compatibility, Intelgic is not just solving a problem—it’s redefining the future of industrial automation.

Discover how Intelgic’s AI-powered machine vision solutions can transform your pipe counting operations with unmatched accuracy, speed, and reliability.

Whether you're looking to optimize a single production line or scale across multiple facilities, our team is here to help you design a solution tailored to your operational needs.