How Machine Vision AI is enhancing accuracy of Aluminium profile counting in Warehouses

Published on: Apr 17, 2025

Written by: Content team, Intelgic

How Machine Vision AI is enhancing accuracy of Aluminium profile counting in Warehouses

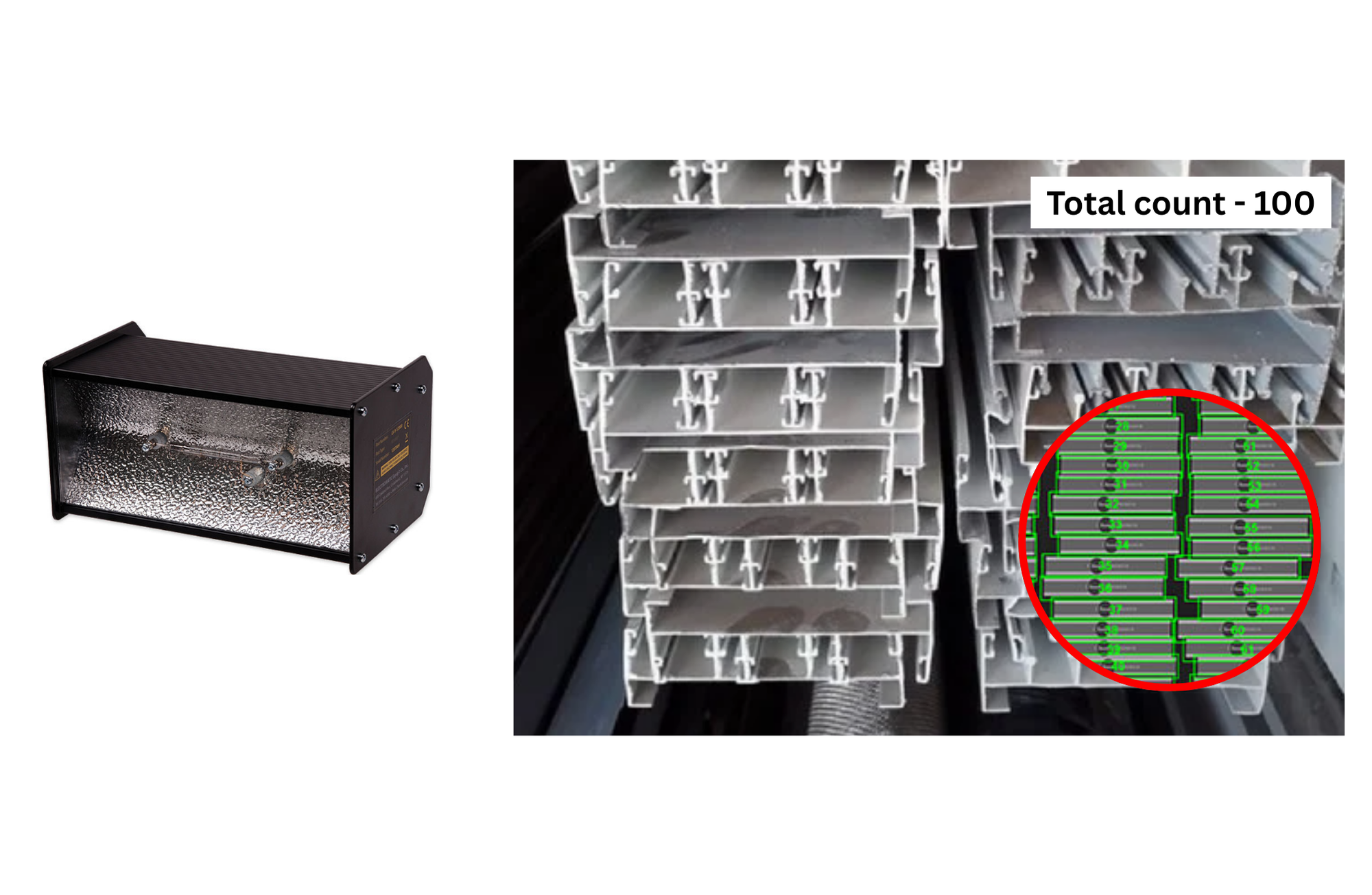

In today’s fast-paced manufacturing and logistics industries, managing inventory with accuracy is more critical than ever. Warehouses dealing with aluminium profiles—commonly used in construction, automotive, aerospace, and furniture manufacturing—face a unique challenge: accurately counting long, reflective, and tightly stacked metal components. Traditional manual counting methods are labor-intensive, error-prone, and time-consuming, often leading to inventory mismatches and operational inefficiencies.To address these limitations, industries are increasingly adopting AI-powered machine vision systems. By leveraging high-resolution area scan cameras, synchronized strobe lighting, and intelligent software capable of real-time analysis, warehouses can now automate the counting of aluminium profiles with remarkable speed and accuracy.

Challenges in Counting Aluminium Profiles

1. Reflective Surfaces

Aluminium profiles have shiny, reflective surfaces that can confuse conventional vision systems. Glare and hotspots from ambient or harsh lighting often result in poor image quality, making accurate detection and counting difficult.

2. Tight Stacking and Similar Appearance

Aluminium profiles are often stored in tight bundles with uniform appearance, making it hard for traditional systems or manual labor to distinguish individual pieces.

3. Irregular Orientation

Profiles may not always be perfectly aligned—some may be tilted, overlapping, or stacked at angles—adding complexity to automated detection and counting systems.

4. High Throughput Requirements

Warehouses handling thousands of profiles per day need fast and reliable counting systems that don’t interrupt the workflow. Manual counting slows down operations and introduces inconsistencies.

The Role of Area Scan Cameras and Strobe Lighting in Accurate Counting

To overcome the above challenges, modern warehouses are adopting machine vision systems integrated with area scan cameras and strobe lighting. Here's how these components contribute to accurate aluminium profile counting:

Area Scan Cameras: Capturing the Full Picture with Precision

Area scan cameras are specially designed to capture a two-dimensional image of the entire field of view in a single frame. In aluminium profile counting, the camera is typically positioned above or alongside the profiles to ensure full visibility of the stacked or bundled materials. As the profiles enter the field of view, the camera captures high-resolution images that preserve every detail—edges, surfaces, and even slight separations between tightly packed profiles.

These rich, high-quality images are then processed by AI algorithms trained to detect, differentiate, and count individual profiles. Even in complex scenarios—where profiles may be partially overlapping or irregularly aligned—the camera provides the clarity needed for accurate interpretation.

Key Benefits of Area Scan Cameras:

- High Precision: Captures fine details and edges essential for distinguishing between adjacent or overlapping profiles.

- Zoom and Detail Enhancement: Enables zoomed-in analysis without losing resolution, supporting AI-driven inspections and adjustments.

- AI Compatibility: Produces structured image data ideal for real-time AI processing and automated decision-making.

Strobe Lighting: Enhancing Image Clarity and Reducing Reflection

Strobe lighting synchronizes with the camera to emit short, high-intensity bursts of light, effectively "freezing" motion and eliminating blur during image capture. More importantly, strobe lights help minimize glare and reflections that typically interfere with counting reflective materials like aluminium.

Key Benefits of Strobe Lighting:

- Eliminates Motion Blur: Freezes fast-moving profiles, ensuring sharp image capture even in motion.

- Controls Glare and Shadows: Minimizes the effects of reflection and ambient lighting variations.

- Reliable in Challenging Environments: Delivers consistent image quality even in dusty, dark, or brightly lit warehouse zones.

Real-Time Counting with AI Software

The real power of modern aluminium profile counting systems comes from AI-based software that can analyze captured images in real time. Here's how the process works:

Image Acquisition

Area scan cameras take high-resolution images under controlled lighting provided by strobe flashes. These images are then sent to the AI software for processing.

Image Pre-processing

The AI software applies filters and pre-processing algorithms to enhance the image, reduce noise, and isolate the profiles from the background.

Object Detection and Counting

Using computer vision and deep learning models, the system detects each aluminium profile in the image. These models are trained on thousands of annotated images to distinguish between profiles and background clutter with high accuracy.

Real-Time Output

Once detection is complete, the AI software instantly outputs the count. This data can be displayed on dashboards, integrated with warehouse management systems (WMS), or used for automated sorting, packaging, or quality checks.

Workflow of AI-Powered Machine Vision Counting

Here’s a typical workflow in a warehouse using Intelgic’s AI-powered aluminium profile counting system:

- Setup and Calibration:

- Area scan cameras and strobe lighting units are installed at inspection points (e.g., near incoming or outgoing bays).

- The system is calibrated to the profile dimensions and typical lighting conditions.

- Area scan cameras and strobe lighting units are installed at inspection points (e.g., near incoming or outgoing bays).

- Profile Entry:

- As aluminium bundles move into the counting zone, the system triggers the camera and strobe simultaneously.

- As aluminium bundles move into the counting zone, the system triggers the camera and strobe simultaneously.

- Image Capture and Processing:

- Images are processed by Intelgic’s AI software in real-time.

- Images are processed by Intelgic’s AI software in real-time.

- Counting and Output:

- The number of profiles is calculated and displayed immediately.

- Counts are logged, and discrepancies from expected inventory are flagged.

- The number of profiles is calculated and displayed immediately.

- Integration and Automation:

- Data is integrated with ERP or WMS.

- Optionally triggers downstream actions like labeling, sorting, or alerts.

Applications Across Industries

While aluminium profile counting is a specialized application, the underlying AI-powered machine vision system is highly adaptable and finds use in a variety of sectors:

1. Construction and Building Materials

Used to count aluminium window frames, door profiles, and modular construction parts during inventory and dispatch.

2. Automotive Industry

Counts metal bars, beams, or tubing in manufacturing and quality control.

3. Aerospace

Used to manage high-precision aluminium components that require tight inventory control and traceability.

4. Furniture Manufacturing

Tracks aluminium or metal parts used in furniture assembly, reducing wastage and ensuring production efficiency.

5. Metal Warehouses and Distributors

Ensures accuracy in large-volume shipments, minimizing errors in order fulfillment and customer complaints.

Advantages of AI-Powered Machine Vision Counting

Adopting AI-powered vision systems like Intelgic’s offers several significant advantages:

1. High Accuracy

Eliminates human errors and miscounts even under challenging conditions like reflections or partial occlusion.

2. Speed

Processes hundreds of profiles per minute with instant feedback, boosting throughput and operational efficiency.

3. Consistency

Maintains uniform performance without fatigue or variations in shift quality—ideal for 24/7 operations.

4. Reduced Labor Costs

Minimizes dependency on manual counting, allowing human workers to focus on higher-value tasks.

5. Traceability and Documentation

Each count can be logged, timestamped, and saved for audits or customer transparency.

6. Scalability

Easily expandable to different stations, materials, or even remote warehouses using cloud-based AI deployment.

7. Integration-Ready

Seamlessly connects with existing warehouse management systems, ERPs, or IoT platforms.

Conclusion: Intelgic’s Expertise in Aluminium Profile Counting

At Intelgic, we specialize in deploying AI-powered machine vision solutions tailored to real-world industrial challenges. Our aluminium profile counting system is built with the latest in deep learning, high-speed area scan cameras, and adaptive lighting techniques like strobe flashes—ensuring unmatched accuracy and speed.

With a deep understanding of metal handling workflows, our solutions are not just plug-and-play but are designed for scalability, integration, and robustness. Whether you're a warehouse manager, quality control engineer, or plant operator, Intelgic’s intelligent vision systems can transform your material handling operations with precision and automation.

If you're ready to eliminate manual errors and supercharge your warehouse efficiency, Intelgic is your go-to technology partner.