High Precision Inspection Automation of Reflective Laminate sheets using Machine vision AI

Published on: Apr 15, 2025

Written by: Content team, Intelgic

High Precision Inspection Automation of Reflective Laminate Sheets Using Machine Vision AI

In modern manufacturing, reflective laminate sheets have become integral in various industries such as furniture, automotive, signage, and construction. The demand for visually flawless and dimensionally accurate sheets has pushed manufacturers to adopt cutting-edge technologies for quality inspection. Particularly for large sheets—like the commonly used 8x5 feet reflective laminates—ensuring consistent quality across the entire surface is a significant challenge. When the defect tolerance is as small as 0.5 mm, even minute imperfections can lead to rejection and costly recalls.

This article explores the common defects in reflective laminate sheets, inspection challenges, the critical role of line scan cameras and dark field illumination, the integration of AI-based software for real-time defect detection, and how companies like Intelgic are pioneering in this field with intelligent automation.

Common Defects in Reflective Laminate Sheets

Reflective laminate sheets, due to their high gloss and mirror-like surfaces, are prone to a variety of surface and structural defects during production, storage, and handling. Common defects include:

- Scratches: Often caused by friction from rollers or handling tools.

- Dents and Dings: Caused by mechanical impact or uneven pressure.

- Air Bubbles: Resulting from poor adhesive application or trapped moisture.

- Wrinkles or Waves: Typically due to improper lamination pressure or tension.

- Foreign Particles: Dust or debris trapped between layers or on the surface.

- Color Banding or Streaks: Arising from ink or coating inconsistencies.

- Delamination: Layers separating due to bonding issues.

- Edge Cracks or Chipping: Often due to improper cutting or material stress.

Challenges in Inspecting Reflective Laminates sheet

Inspecting reflective surfaces presents unique challenges that differ from matte or textured materials:

- Glare and Light Scattering: Reflective surfaces cause intense glare and specular reflections, which can obscure defects.

- Low Contrast Defects: Scratches or dents on shiny surfaces often have minimal contrast, making them hard to detect with traditional vision systems.

- High-Speed Production Lines: Inspection systems must operate in real-time to match production speeds without creating bottlenecks.

- Large Surface Area Coverage: 8x5 feet sheets demand wide field-of-view systems that maintain high resolution and speed.

- Environmental Noise: Vibrations, ambient light, and dust can introduce variability in detection accuracy.

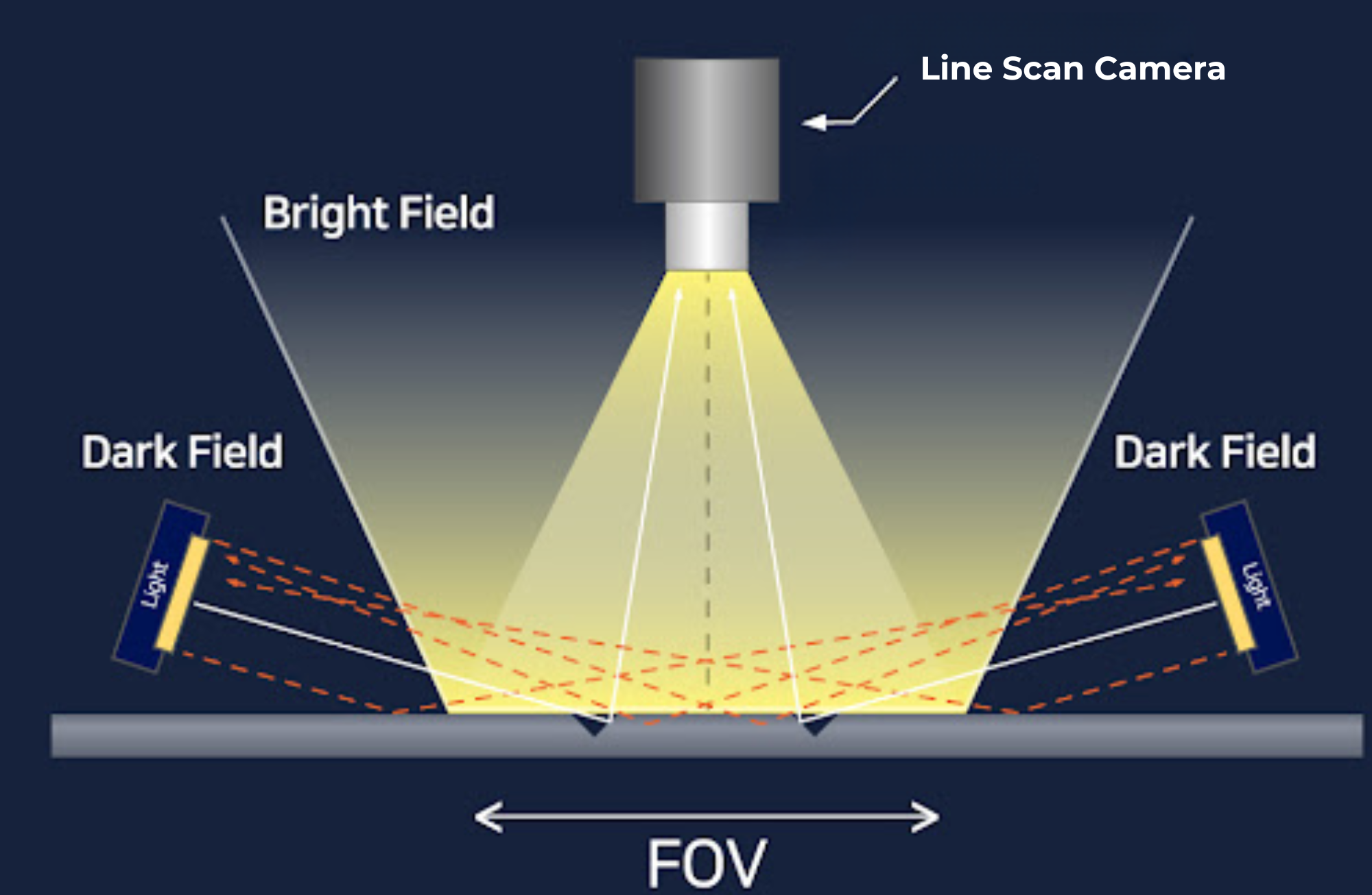

How Line Scan Cameras and Dark Field Illumination Work Together for Flawless Surface Inspection

Two of the most important hardware components in reflective laminate inspection are line scan cameras and dark field illumination systems.

Line Scan Cameras

Line scan cameras capture images one line at a time, making them ideal for continuous surfaces such as large laminate sheets. As the sheet moves along a conveyor, the camera scans the surface line-by-line, building a high-resolution image for analysis.

Advantages of line scan cameras:

- High resolution and speed suitable for detecting 0.5 mm defects at fast conveyor speeds.

- Uniform illumination and image consistency across the entire sheet.

- No motion blur due to synchronized triggering with conveyor movement.

Dark Field Illumination

Dark field illumination involves projecting light at a low angle across the surface of the sheet. Defects like scratches and dents scatter the light, causing them to appear bright against a dark background.

Benefits of dark field lighting:

- Enhances visibility of low-contrast surface anomalies.

- Minimizes glare from the reflective surface.

- Provides sharp edge definition for minute defects.

Together, line scan cameras and dark field illumination form a robust vision setup that overcomes the optical challenges of reflective sheet inspection.

Real-Time Defect Detection Using AI Software

Traditional rule-based image processing has limitations when it comes to adaptive learning and detecting subtle, complex patterns. AI-powered defect detection software revolutionizes this process through:

1. Deep Learning Algorithms

AI models are trained on a large dataset of defective and non-defective laminate images. These models learn to recognize subtle patterns and deviations from the norm, including:

- Micro-scratches and hairline cracks

- Pattern inconsistencies

- Surface contamination

2. Real-Time Processing

By leveraging GPUs and edge computing, AI software processes image data from line scan cameras in real time. This enables:

- Instant identification and classification of defects

- Triggering of alarms or rejection mechanisms

- Live visualization for operators on the shop floor

3. Self-Learning Capabilities

The system can continuously improve by retraining on newly discovered defect types or materials, ensuring it stays effective in evolving manufacturing environments.

Workflow of Reflective Laminate Sheet Inspection in Manufacturing

Here’s a typical workflow of an automated inspection setup for 8x5 feet reflective laminate sheets:

- Sheet Movement: The reflective laminate sheet moves along a conveyor system at a consistent speed.

- Dark Field Illumination: Light is cast at shallow angles across the sheet’s surface.

- Image Acquisition: Line scan cameras synchronized with the conveyor capture high-resolution images.

- Image Preprocessing: Raw images are filtered and normalized to remove noise.

- AI Analysis:

- Deep learning models analyze image slices.

- Defects are classified, sized, and their coordinates mapped.

- Deep learning models analyze image slices.

- Result Handling:

- Accept/reject decision made.

- Defective sheets are flagged or automatically removed.

- Data logged for traceability and process improvement.

- Accept/reject decision made.

- Operator Dashboard: Real-time status, defect type, severity, and location displayed visually.

Advantages of AI-powered Machine Vision Reflective Sheet Inspection

|

Feature |

Benefit |

|

High Detection Accuracy |

Identifies defects as small as 0.5 mm with minimal false positives |

|

Speed |

Matches or exceeds production line speed without delay |

|

Consistency |

Eliminates human subjectivity and fatigue |

|

Traceability |

Data logged for quality reporting and process optimization |

|

Cost Reduction |

Minimizes waste and reduces returns due to poor quality |

|

Scalability |

Easily adaptable to different sheet sizes and materials |

|

Continuous Learning |

AI models improve with time and data volume |

Intelgic’s Expertise in Machine Vision-Based Quality Control

As industries continue to demand higher quality standards and zero-defect manufacturing, intelligent inspection systems have become a necessity. The inspection of 8x5 feet reflective laminate sheets with 0.5 mm defect detection tolerance is a prime example of how precision meets innovation.

Intelgic stands at the forefront of this transformation with its Live Vision AI-based inspection software. By combining high-speed line scan cameras, optimized dark field illumination, and state-of-the-art AI algorithms, Intelgic delivers real-time, high-accuracy inspection solutions that seamlessly integrate into your production environment.

With proven deployments across manufacturing sectors and a strong track record in defect detection, Intelgic empowers manufacturers to achieve excellence in quality, reduce costs, and stay ahead of the curve in a competitive market.