Detecting Color Defects Using Machine Vision AI

Published on: Jun 03, 2025

Written by: Content team, Intelgic

Detecting Color Defects Using Machine Vision AI

In today’s fast-paced and highly competitive manufacturing landscape, ensuring exceptional product quality is not just a goal—it’s a necessity. Among the various parameters that define quality, color consistency stands out as a critical factor, particularly in visually sensitive industries such as automotive, textiles, packaging, printing, and consumer goods. A seemingly minor shift in color shade or tone can lead to product rejections, damaged brand perception, or customer dissatisfaction, costing manufacturers both reputation and revenue. Yet, manual inspection of color defects remains inherently flawed—it is often subjective, inconsistent, and incapable of keeping pace with modern production speeds. This is where Machine Vision AI emerges as a transformative force, delivering unparalleled accuracy, speed, and efficiency in detecting even the most subtle color deviations. With its ability to operate continuously, learn from data, and eliminate human error, Machine Vision AI is redefining the standards of quality assurance in color inspection.

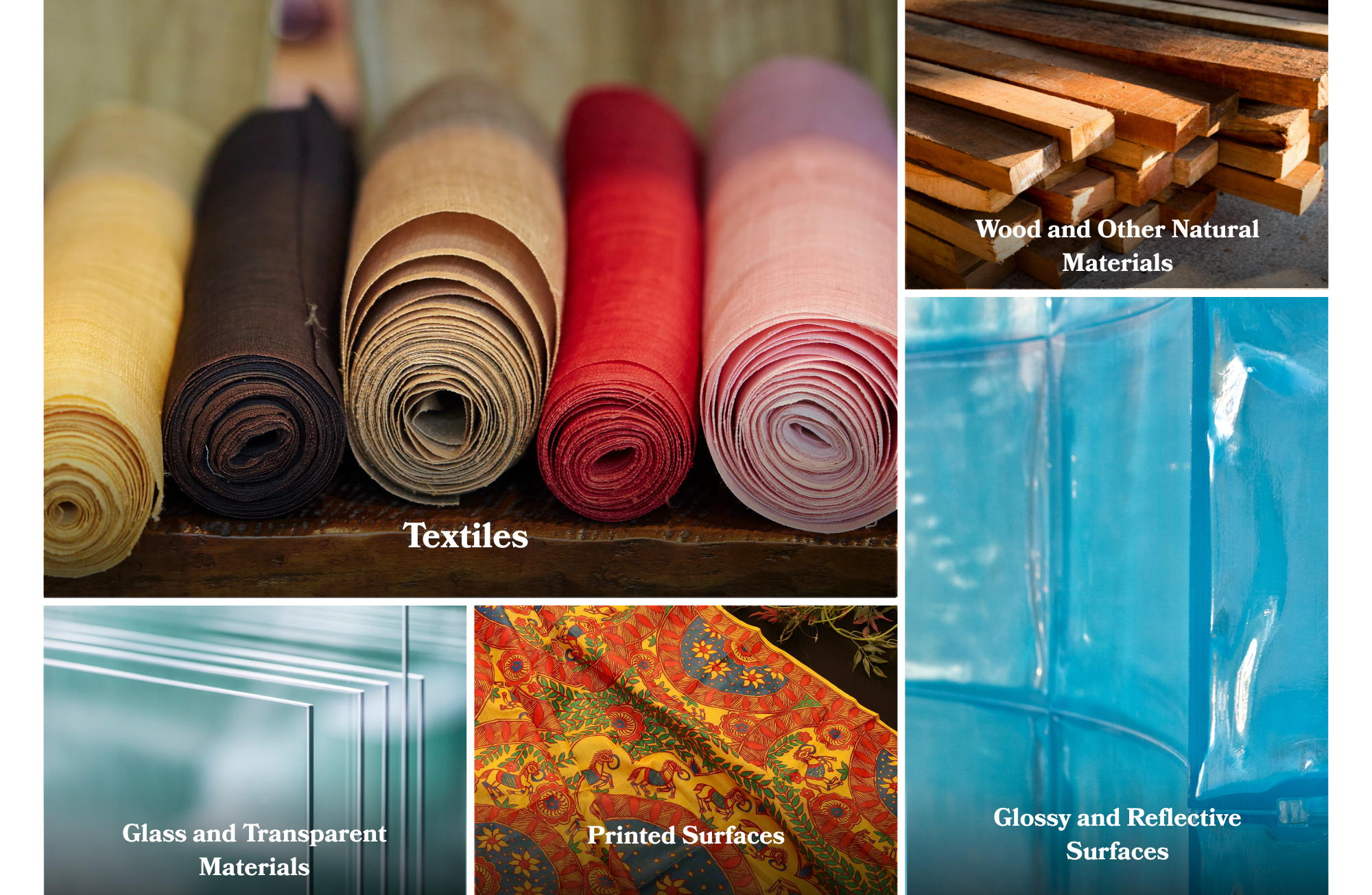

Common Color Defects Across Different Materials

- Textiles

- Shade variations across fabric batches

- Inconsistent dye saturation, resulting in uneven tone

- Color bleeding from adjacent fabrics or during washing

- Streaks and blotches caused by faulty weaving or dye application

- Shade variations across fabric batches

- Wood and Natural Materials

- Uneven staining or poor absorption of finishes

- Dark patches or burn marks from processing

- Faded or washed-out areas due to environmental exposure

- Chemical discoloration during treatment or finishing

- Uneven staining or poor absorption of finishes

- Glossy and Reflective Surfaces (Plastics, Metals)

- Tint inconsistencies due to improper coating or curing

- Color banding from uneven application of paint or lacquer

- Heat marks or oxidation spots on metal surfaces

- Surface clouding that distorts perceived color

- Tint inconsistencies due to improper coating or curing

- Printed Surfaces

- Incorrect color tones from mismatched ink formulations

- Color misalignment from poor print registration

- Fading over time, particularly around edges

- Ink bleeding or overlapping that compromises print clarity

- Incorrect color tones from mismatched ink formulations

- Glass and Transparent Materials

- Uneven tint distribution across panels

- Coating inconsistencies causing visible discoloration

- Trapped particles or bubbles that affect visual uniformity

- Haze or rainbow-like effects (iridescence) due to surface treatments

- Uneven tint distribution across panels

Challenges in Detecting Color Defects Across Different Materials

Detecting color defects is far from a straightforward process—it’s a highly nuanced task that varies significantly depending on the material being inspected. Each material introduces its own unique set of challenges that can compromise the accuracy of conventional inspection methods.

Textiles

-

Often feature complex weaves and varied surface textures.

-

These intricacies can alter how colors are perceived, especially under changing lighting conditions.

-

This makes it difficult to distinguish between intended design elements and actual color defects.

Wood and Other Natural Materials

-

Contain natural grain patterns, knots, and tonal variations.

-

While often considered part of the material’s appeal, these inherent inconsistencies can be misread as flaws by traditional inspection systems.

Glossy and Reflective Surfaces (e.g., Plastics, Metals)

-

Known to reflect light unevenly, causing glare, hotspots, and shadows.

-

These visual artifacts can interfere with accurate color capture, resulting in false positives or undetected defects.

Printed Surfaces

-

May experience ink inconsistencies, color bleeding, or fading during production or over time.

-

Such defects are often subtle and require high-precision, adaptive inspection systems to detect reliably.

Glass and Transparent Materials

-

Present unique challenges due to their transparent or translucent nature.

-

Color defects like tint variations, coatings inconsistencies, or embedded particles are difficult to detect with conventional vision systems.

-

Refractions, reflections, and edge distortions further complicate the inspection process, demanding highly specialized imaging and intelligent processing.

Machine Vision AI: A Game-Changer in Color Defect Detection

Machine Vision AI is revolutionizing color defect detection by integrating high-performance imaging hardware with advanced deep learning algorithms. These intelligent systems learn from golden templates—ideal product samples—to detect even the slightest color deviations that often escape human observation. They adapt to variations in texture and lighting, ensuring consistent precision and reliability across different materials.

High Resolution Machine Vision Cameras in Inspection

In Machine Vision AI systems, the choice of camera plays a crucial role in accurately detecting color defects across various types of materials. Two primary imaging technologies are employed: Line Scan Cameras and Area Scan Cameras, each suited for specific inspection needs.

- Line Scan Cameras

Perfect for inspecting continuous or roll-based materials such as fabrics, paper, metal sheets, and wooden panels. These cameras capture one line of pixels at a time as the material moves beneath them, creating a seamless, high-resolution image of the entire surface. Line scan systems offer exceptional detail, uniform lighting control, and precise detection of subtle color inconsistencies across long and wide production lines.

- Area Scan Cameras

Ideal for inspecting individual or discrete objects like molded parts, circuit boards, packaging, or assembled products. These cameras capture full-frame images in a single snapshot, enabling quick analysis of color uniformity and defect detection across defined areas. Their versatility, high-speed performance, and broad application range make them essential in many automated inspection systems.

Advanced Illumination Techniques for Enhanced Accuracy

Illumination is a vital component in achieving precise color defect detection. Modern inspection systems use advanced lighting techniques to enhance visibility and accuracy, including:

- Direct lighting, which provides intense, focused illumination to clearly reveal subtle color variations and surface flaws.

- Diffuse dome lighting, which minimizes shadows and reflections by evenly distributing light across textured or complex surfaces.

- Structured lighting, which enhances surface details and irregularities that may affect color perception and defect visibility.

Role of AI Software: Detecting Deviations from the Golden Template

AI software acts as the intelligent core of modern color defect detection systems. Leveraging deep learning algorithms trained on golden templates—which are flawless, ideal samples of the product—the AI develops an in-depth understanding of whOnce deployed, the AI can:

- Detect even the slightest color shifts that fall outside the acceptable range, catching subtle defects invisible to the human eye.

- Distinguish true defects from natural variations inherent in materials, minimizing false positives.

- Classify defects by severity, location, and pattern, enabling prioritized responses and targeted quality improvements.

Importantly, the AI continually enhances its accuracy over time through feedback loops and ongoing learning, adapting to new data and evolving production conditions. This continuous improvement empowers real-time quality control, automated defect sorting, and detailed reporting—ultimately driving higher product consistency, reducing waste, and improving traceability throughout the manufacturing process.

Applications Across Industries

Machine Vision AI–powered color defect detection is revolutionizing quality control across a diverse range of industries by delivering unmatched precision and consistency.

- Automotive

In automotive manufacturing, maintaining flawless color consistency is essential for both aesthetic appeal and brand reputation. AI-driven inspection ensures uniformity in paint finishes, body panels, and interior components, catching even the slightest discoloration or blemishes that could affect the final product quality.

- Textiles

The textile industry benefits greatly from advanced color defect detection by identifying subtle dye inconsistencies, stains, and printing errors on fabrics. This technology helps maintain color accuracy across different batches and detects flaws that could compromise fabric appearance and customer satisfaction.

- Pharmaceuticals & Cosmetics

Accurate color detection is critical in pharmaceuticals and cosmetics, where packaging and product coloration must meet stringent regulatory standards. Machine Vision AI identifies incorrect labeling, off-color products, and packaging defects, ensuring safety, compliance, and consumer trust.

- Electronics

In electronics manufacturing, consistent color across casings, buttons, and LED displays is key to product appeal and quality perception. AI systems monitor these components in real time, detecting any color mismatches or defects that may impact device aesthetics or functionality.

- Food & Beverage

Color plays a vital role in assessing freshness and quality in the food and beverage industry. Machine Vision AI detects discoloration, spoilage, or contamination in products and packaging, helping manufacturers maintain safety standards and deliver high-quality goods to consumers.

Future Trends Shaping Machine Vision AI in Color Defect Detection

As Machine Vision AI technology continues to evolve, several exciting trends are poised to redefine its capabilities and impact across industries:

- Edge AI Integration: By enabling faster, on-device processing, Edge AI reduces latency and reliance on centralized servers. This allows real-time defect detection and decision-making directly on the production line, enhancing responsiveness and minimizing downtime.

- AI-Driven Predictive Maintenance: Advanced AI models are being used to predict and prevent equipment failures before they cause defects. This proactive approach helps maintain consistent production quality and reduces costly interruptions.

- Augmented Reality (AR) Overlays: AR technology is being integrated to provide operators with real-time, visual feedback during inspections. This intuitive guidance improves accuracy and speeds up defect resolution, empowering frontline workers with actionable insights.

- Cloud-Based Analytics: Centralized cloud platforms collect and analyze inspection data from multiple global facilities. This unified view enables comprehensive quality monitoring, trend analysis, and informed decision-making at scale.

- Accessible AI Training Platforms: Emerging platforms are simplifying AI model development, allowing even non-experts to build and customize robust inspection systems. This democratization of AI technology accelerates adoption and innovation across diverse manufacturing environments.

Intelgic at the Forefront of Color Defect Detection

Intelgic leads the way in revolutionizing color defect detection through advanced Machine Vision AI. By seamlessly integrating state-of-the-art cameras, sophisticated illumination, and proprietary AI software, these solutions deliver unmatched accuracy, efficiency, and scalability for modern manufacturing.

- Unparalleled Precision: Detecting even the most subtle color deviations to ensure flawless product quality.

- Cutting-Edge Technology: Utilizing both line scan and area scan cameras alongside advanced lighting for consistent inspection across various materials.

- Flexible and Scalable: Solutions designed to fit diverse production volumes and evolving manufacturing needs.

- Deep Industry Expertise: Tailored approaches based on extensive experience across multiple sectors.

- Enhanced Operational Efficiency: Minimizing waste and rework to improve productivity and cost-effectiveness.

Intelgic is committed to helping your business achieve the highest quality standards with intelligent inspection systems that drive measurable results.

Connect with Intelgic to explore the innovative solutions for transforming your color defect detection.