Design Defects Inspection in Manufacturing with Machine Vision AOI

Published on: May 30, 2025

Written by: Content team, Intelgic

Design Defects Inspection in Manufacturing with Machine Vision AOI

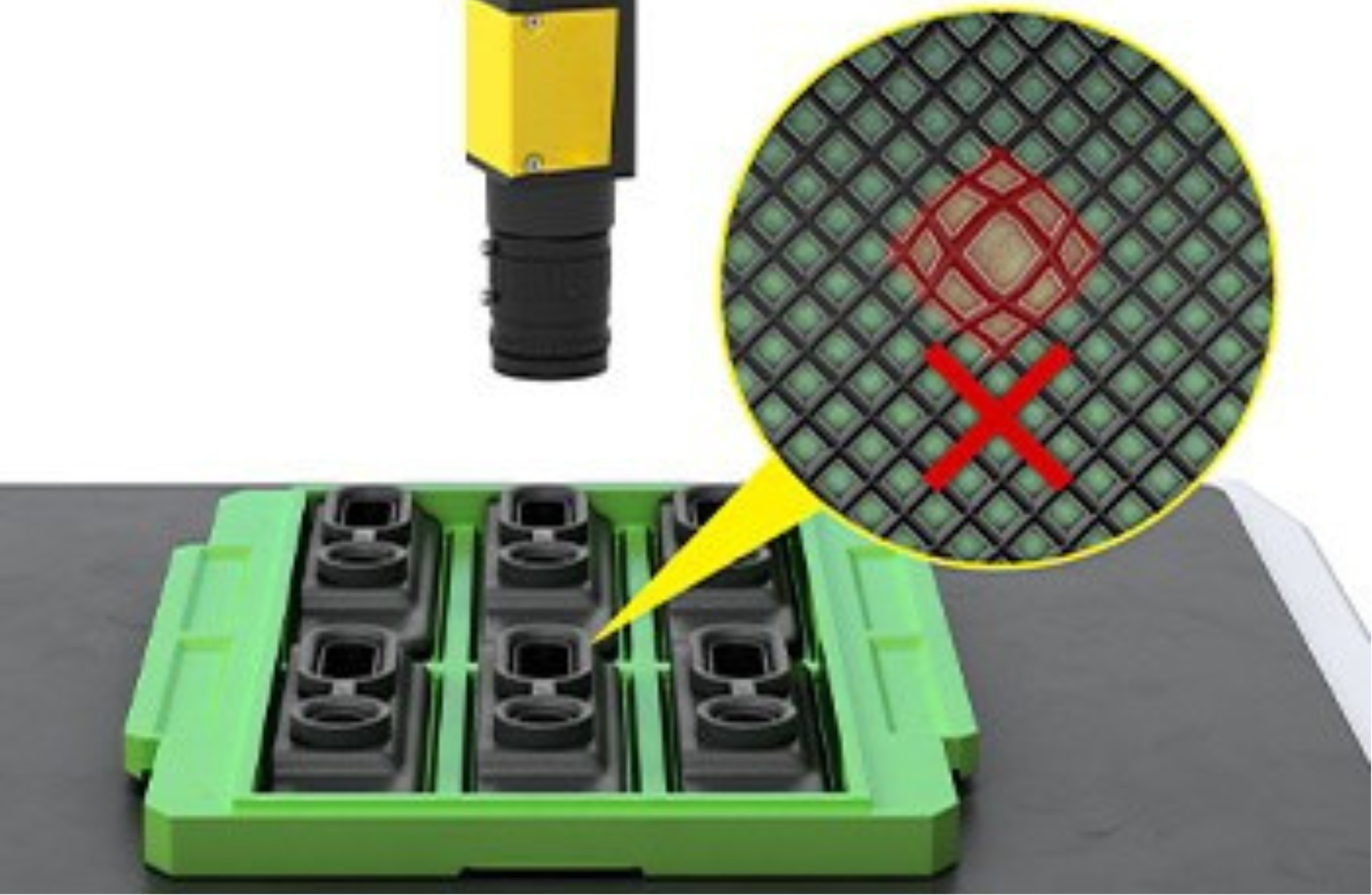

In today’s fast-paced manufacturing environment, quality assurance plays a crucial role across a wide array of industries including electronics, automotive, aerospace, pharmaceuticals, and consumer goods. Each of these sectors produces complex products with intricate designs that must adhere to exacting specifications. A single design defect can lead to product failures, safety hazards, costly recalls, or damage to brand reputation. Traditionally, design defect inspection has been a labor-intensive and error-prone task, relying heavily on human inspectors. However, with the rise of automation and digital transformation, Machine Vision Automated Optical Inspection (AOI) has emerged as a game-changing technology that enhances precision, speed, and reliability in detecting design flaws.

Challenges in Design Defect Inspection

Design defect inspection is inherently complex due to the diversity in product materials, geometries, and production environments. Major challenges include:

- High volume and speed requirements: Modern production lines require continuous, real-time inspection without slowing down operations.

- Small and subtle defects: Minor deviations in design patterns or alignments are often too subtle for the human eye to catch consistently.

- Complex product geometries: Intricate, multi-layered, or irregularly shaped products can obscure defects and complicate visual inspection.

- Material types and reflective surfaces: Shiny, glossy, or transparent materials (such as metals, plastics, or glass) can cause glare or reflections, making it difficult to detect surface-level and embedded design flaws.

- Subjectivity and inconsistency: Human inspectors may interpret visual cues differently, leading to variability in inspection results.

- Cost and resource constraints: Manual inspection requires significant labor, expertise, and training—leading to high operational costs and scalability issues.

How Machine Vision AOI Overcomes These Challenges

Machine Vision AOI leverages high-resolution machine vision cameras, advanced lighting systems, and AI-powered software to address the above challenges effectively

High Resolution Machine Vision Cameras: Capturing Precision in Detail

Before any defect detection can take place, capturing precise and clear images is critical. High-resolution Machine Vision cameras play a pivotal role by providing:

- Crisp, ultra-detailed images that reveal even the most subtle design deviations.

- The ability to capture fine textures, small components, and intricate patterns with exceptional clarity.

- Consistent image quality that supports accurate analysis regardless of product complexity or inspection speed.

Area Scan Cameras:

Area scan cameras capture the entire product or a section of it in a single frame. This makes them ideal for inspecting discrete parts or stationary items. In design defect inspection, area scan cameras:

- Take high-resolution snapshots to detect missing features, incorrect patterns, or surface anomalies.

- Allow simultaneous analysis of multiple regions on the product, speeding up the inspection.

- Are commonly used when products stop briefly for inspection or move at slower speeds.

Line Scan Cameras:

Line scan cameras capture images one line at a time, scanning continuously as the product moves on a conveyor. This setup is perfect for inspecting long or continuous materials, such as wood panels, textiles, or printed circuits.

In design defect detection, line scan cameras:

- Build a high-resolution image by stitching multiple line scans together, creating a continuous, seamless image of the entire surface.

- Detect defects such as scratches, misalignments, or missing design elements over large surfaces without stopping production.

- Provide very high throughput inspection suitable for fast-moving production lines.

Advanced Lighting: Enhancing Visibility and Contrast

Advanced lighting systems work alongside high-resolution cameras to improve image clarity and defect detection. They help:

- Eliminate shadows, glare, and reflections.

- Enhance contrast and reveal fine surface details.

- Maintain consistent illumination during high-speed inspections.

Different Lighting Types Are Used:

- Structured Lighting: For 3D features or surface warping.

- Diffuse Dome Lighting: Ideal for shiny or curved surfaces to reduce glare.

- Ring Lights: Used for general flat surface inspection with even illumination.

- Coaxial Lighting: Best for smooth, reflective surfaces like PCBs to highlight fine design features.

AI Software in Preparing the Golden Template and Detecting Design Defects

A critical step in Machine Vision AOI is creating a golden template — a perfect reference model representing the flawless design of the product. This template is prepared by:

- Collecting multiple images of defect-free products captured under standardized lighting and camera settings.

- Processing these images to create a comprehensive digital model that encapsulates all design details and acceptable tolerances.

- Feeding this model into the AI software to train it on what a "perfect" design looks like.

Once trained, the AI software inspects each product on the production line by capturing images and comparing them pixel-by-pixel against the golden template. The software detects any design deviations such as missing components, incorrect patterns, misalignments, or unwanted anomalies. It can also classify defects by severity and type, enabling precise quality control and rapid decision-making.

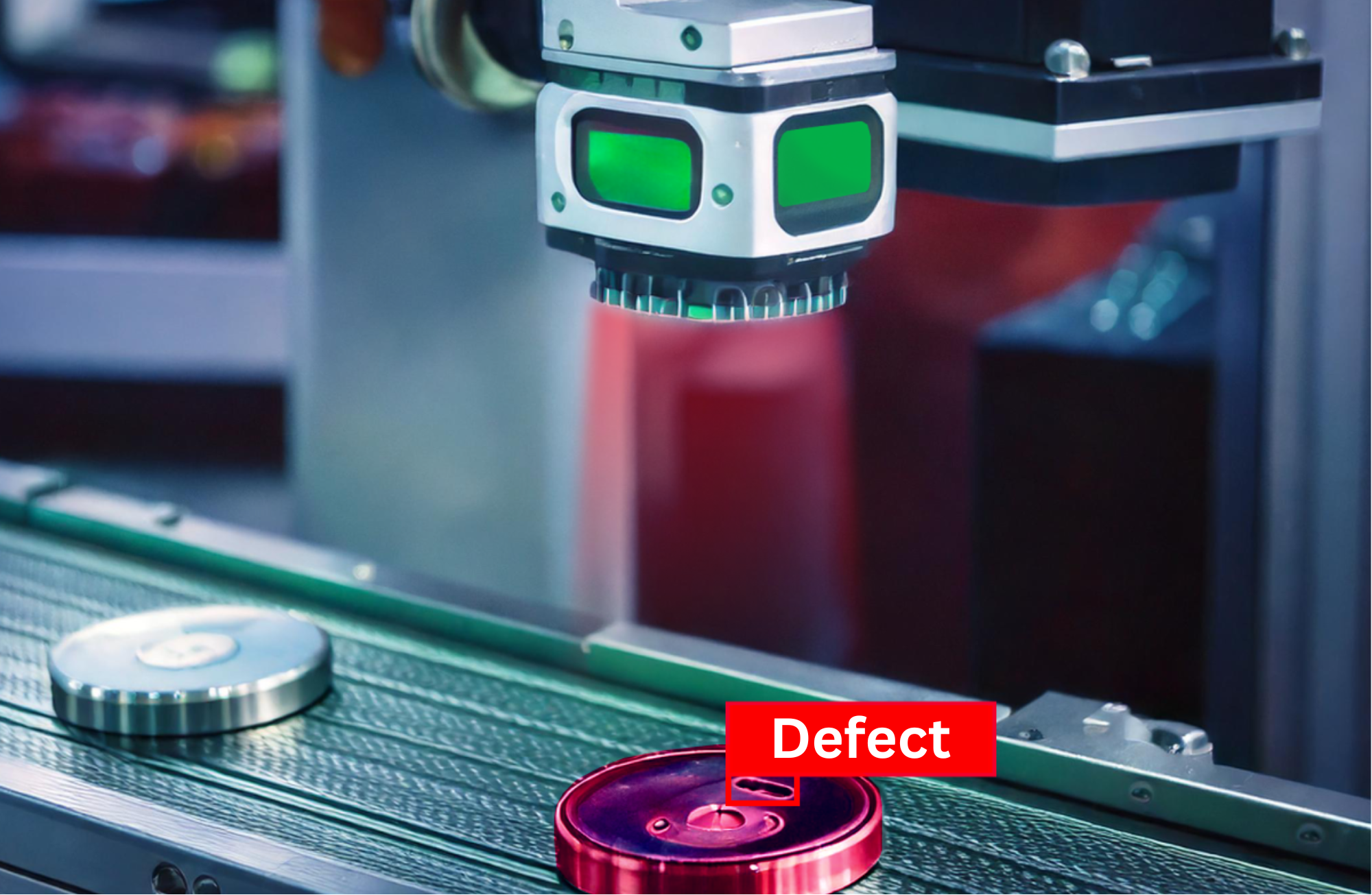

Inspection Process Workflow

The design defect inspection process using Machine Vision AOI follows a structured and intelligent workflow to ensure precision, speed, and consistency:

1. Product Placement

The product enters the inspection station—typically on a conveyor system—where it is accurately positioned to ensure repeatable image capture. Proper alignment is crucial for consistent inspection results.

2. Image Capture

High-resolution area scan or line scan cameras, in coordination with optimized lighting (structured, dome, ring, or coaxial), capture detailed images of the product’s surface. This stage ensures every element of the design is clearly visible for analysis.

3. Image Pre-processing

Captured images are digitally enhanced to amplify critical design features. Techniques such as contrast adjustment, noise reduction, and edge sharpening are applied to improve visibility of fine details, especially on complex or reflective surfaces.

4. Golden Template Comparison

The AI software compares the captured image against a pre-defined “golden template”—a reference model representing the ideal, defect-free design. This template is either generated or learned through training on validated product samples.

5. AI-Based Defect Detection

Using pattern recognition and deep learning algorithms, the system detects any deviations from the golden template. These can include missing components, misalignments, dimensional inaccuracies, or unwanted design shifts. Detected defects are classified based on severity, type, and location.

6. Real-Time Feedback

The system immediately alerts operators with visual overlays, alarms, or dashboard updates. Detailed defect reports and annotated images are generated, enabling quick diagnosis and action.

7. Sorting or Rework Decision

Defective products are automatically flagged for rejection, rework, or further manual review. Integration with robotic sorters or conveyors allows for seamless removal or redirection of flawed items from the production line.

.jpg)

Benefits of Machine Vision AOI in Design Defect Detection

Implementing Machine Vision AOI offers a wide range of benefits that significantly enhance quality assurance and operational efficiency in modern manufacturing. These include:

- High Accuracy and Consistency

Machine Vision systems deliver precise, repeatable results, reducing missed defects and false positives. Unlike human inspectors, AOI systems maintain consistent performance over time and across shifts.

- Faster Inspection Cycles

Automated inspection dramatically reduces cycle times, enabling real-time analysis without slowing down the production line. This keeps operations lean and responsive.

- Reduced Labor Costs and Human Error

By automating visual inspection tasks, manufacturers can reduce dependency on manual labor, minimize fatigue-related errors, and lower training requirements.

- Enhanced Data Collection and Traceability

AOI systems generate detailed records of inspections, including images and defect classifications. This data can be used for root cause analysis, continuous improvement, and compliance documentation.

- Scalability and Flexibility

Machine Vision AOI can be adapted to inspect various materials, product types, and industries—from electronics and automotive to wood panels and consumer goods—making it a versatile solution for quality control.

Intelgic: Pioneering the Future of Design Defect Inspection

Intelgic leads the way in modern design defect detection with its advanced Live Vision software and automated optical inspection (AOI) systems. By combining high-resolution imaging technology with intelligent AI algorithms, Intelgic delivers fast, accurate, and scalable defect detection solutions suitable for a wide range of industries and applications.

Key Advantages of Intelgic’s AOI System:

- High-Precision Defect Detection

Accurately identifies fine and complex design deviations to ensure superior product quality.

- AI-Powered Decision Making

Utilizes proprietary algorithms to classify defects and continuously enhance inspection accuracy.

- Optimized Imaging Hardware

Employs area scan and line scan cameras paired with customized lighting tailored to diverse materials and surface types.

- Real-Time Monitoring and Feedback

Offers immediate defect reports and alerts, enabling quick decision-making and minimizing production delays.

- Seamless Integration

Easily adapts to existing manufacturing lines for automated quality control, defect sorting, and process optimization.

As product designs grow more intricate and manufacturing demands increase, the importance of fast, accurate, and intelligent inspection continues to rise. Machine Vision AOI, driven by high-resolution imaging, advanced lighting, and AI software, is revolutionizing how industries detect and handle design defects. It reduces reliance on manual inspection, enhances quality, and boosts production efficiency across a wide range of materials and product types.

Intelgic is at the forefront of this transformation. With its cutting-edge Live Vision software and integrated AOI solutions, Intelgic is setting new benchmarks in automated defect detection. By combining proprietary AI algorithms with optimized imaging systems, Intelgic empowers manufacturers—especially in wood panel and design-intensive industries—to ensure product excellence, minimize waste, and future-proof their quality control processes.

Machine Vision AOI is no longer just an option—it's becoming the standard, and innovators like Intelgic are leading the way.