Defects Counting in Manufacturing using Machine Vision AI

Published on: Jun 03, 2025

Written by: Content team, Intelgic

Defects Counting in Manufacturing using Machine Vision AI

In today's competitive and quality-driven manufacturing landscape, identifying defects is no longer enough—accurately counting the number of defects has become a critical requirement across industries. In many sectors, especially those dealing with high-precision products such as automotive components, electronics, wood panels, glass, and semiconductors, a limited number of small or micron-level defects may be tolerated within strict quality thresholds. However, when the defect count exceeds those predefined limits, even if the individual flaws are minor, the product may be downgraded, flagged for rework, or rejected altogether.

This makes defect counting far more than a surface-level inspection task. It directly impacts product grading, compliance, safety, customer satisfaction, and operational costs. High defect counts can reveal underlying production issues, material inconsistencies, or environmental problems that require immediate intervention.

Manual inspection methods often fall short in this context—especially when it comes to detecting and tracking small, repetitive, or fast-occurring defects. They lack the speed, precision, and consistency required for high-throughput environments. As a result, manufacturers are turning to Machine Vision AI, which combines high-resolution cameras, advanced lighting, and intelligent software to accurately detect, classify, and count defects—even those invisible to the human eye.

Why Defect Counting Is Essential

In many precision-driven industries, not all defects automatically lead to rejection. In fact, a certain number of minor or micron-level defects—those too small to affect performance or aesthetics—are often considered acceptable within predefined quality thresholds. For example, in automotive paint finishing, a few tiny dust specks might be allowed; in wood panels, a limited number of knots or discolorations may still qualify a piece as usable; and in semiconductor or glass inspection, sub-micron scratches may fall within tolerance.

However, it’s the count of these defects that plays a critical role. While one or two small imperfections may pass quality control, a higher accumulation of defects—even if individually minor—can trigger product rejection, rework, or downgrading. Exceeding the allowable defect count often signals deeper issues in the production process, such as equipment wear, raw material inconsistencies, or environmental contamination.

This makes defect counting not just a technical task, but a strategic necessity. Manufacturers must know exactly how many defects occur on each product or batch to:

- Ensure they remain within acceptable quality thresholds

- Prevent faulty items from reaching customers

- Detect early signs of process degradation or failure

- Maintain compliance with internal and regulatory standards

- Decide whether a product should pass, be reworked, or scrapped

Manual inspection methods are prone to inconsistency and fatigue, making it nearly impossible to detect and count tiny, fast-occurring, or high-volume defects with the precision required today. This is where Machine Vision AI excels—offering accurate, real-time defect counting at both macro and micron levels, helping manufacturers maintain control over product quality while optimizing efficiency.

How Machine Vision AI Counts Defects

In modern manufacturing, defect counting is a vital part of quality assurance. Machine Vision AI systems are designed to perform general defect counting across the entire product surface, ensuring no irregularities are missed. Alongside this, manufacturers can also define predefined Regions of Interest (ROIs)—specific areas known to be more prone to defects due to material stress, design sensitivity, or critical functional roles.

Machine Vision AI handles both tasks seamlessly: it automatically detects and counts defects across the whole product while also focusing on region-specific inspection zones for enhanced accuracy where it matters most. This dual approach maximizes inspection efficiency and ensures that products meet stringent quality standards—both in terms of total defect count and location-specific thresholds.

1. High-Resolution Machine Vision Cameras

At the heart of Machine Vision AI are high-resolution industrial machine vision cameras designed to capture fine details across both specific zones and general surfaces. These cameras can scan rapidly moving products and generate crisp, high-definition images that reveal micron-level imperfections such as cracks, surface scratches, blemishes, or stains.

Because they can be calibrated to focus on both predefined ROIs and the overall product surface, these cameras ensure a comprehensive inspection—no detail is missed, whether it's a high-risk weld joint or an unexpected flaw in an otherwise stable region.

2. Advanced Illumination Techniques

Accurate defect detection relies not only on camera resolution but also on optimized lighting. Machine Vision systems use specialized illumination techniques to highlight surface variations and reveal hidden defects.

Key lighting techniques include:

- Structured Light – projects patterns to detect surface contours and indentations

- Backlighting – used to reveal cracks, holes, or shape deviations by creating sharp contrast

- Diffuse Dome Lighting – eliminates shadows and glare for reflective or curved surfaces

Illumination can be strategically applied to ROIs for enhanced detail, while still covering the broader product surface. This ensures consistent visibility of both localized and distributed defects.

3. Intelligent AI Software for Defects Detection and Counting

After imaging, the AI-powered software takes control—analyzing both the specified inspection zones and the entire product surface to detect, classify, and count defects.

Here’s how it works:

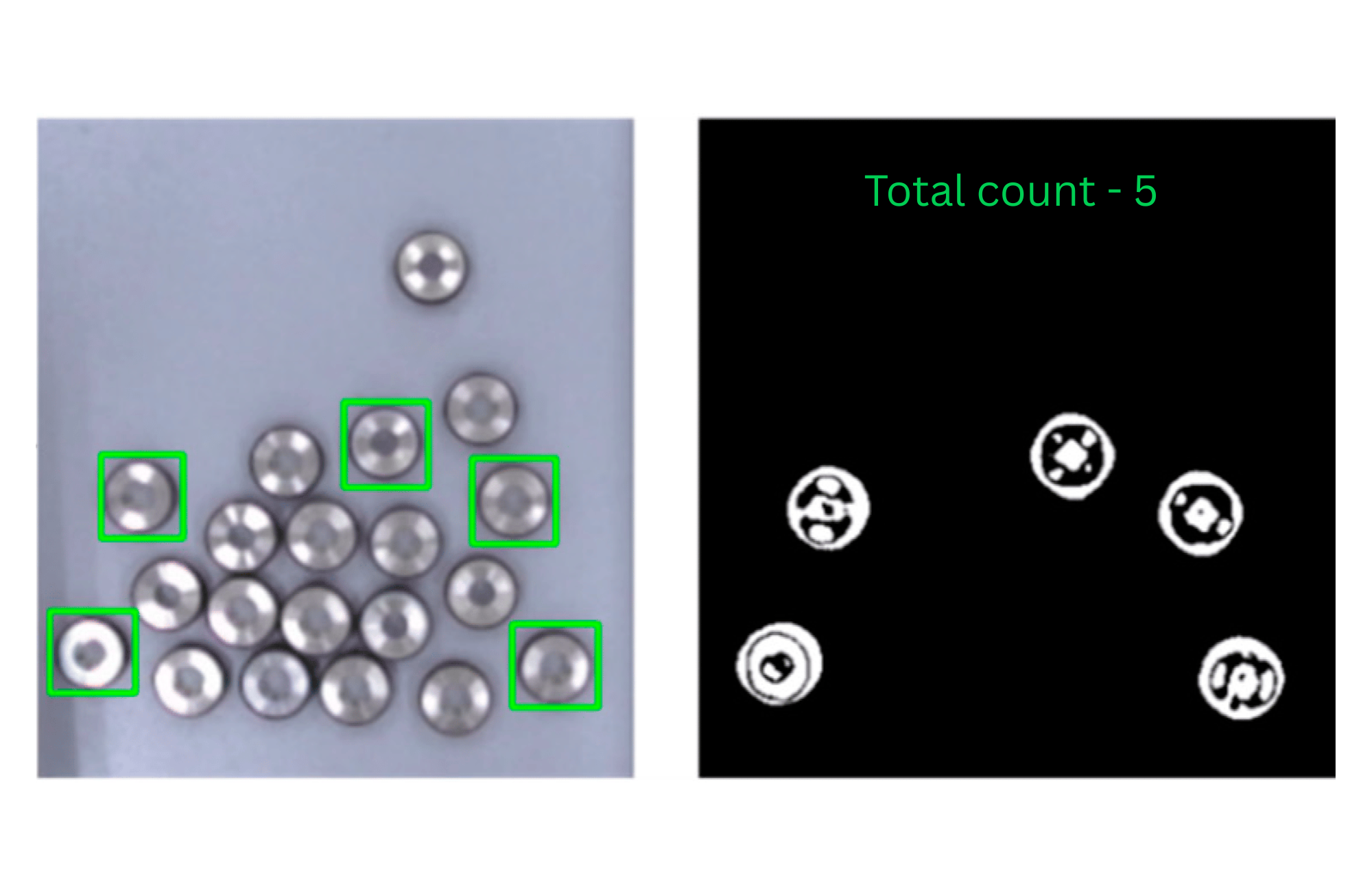

- Region Selection: The software focuses on user-defined Regions of Interest while simultaneously scanning non-critical zones. This parallel inspection approach enhances defect coverage and quality assurance.

- Defect Detection & Classification: Using deep learning and advanced computer vision, the AI detects anomalies in texture, color, shape, and size. It identifies both expected defect types and novel variations.

- Counting & Categorization: Based on customizable thresholds, the software counts the defects and classifies them into categories such as acceptable, reworkable, or rejects. Products exceeding the maximum allowed defect count are automatically flagged or rejected.

- Real-Time Reporting: The system presents inspection results via a real-time dashboard, showing defect locations, counts, and trends—empowering quality control teams to make data-driven decisions immediately.

Advantages of Machine Vision AI in Defect Counting

Implementing Machine Vision AI offers several game-changing benefits:

- High Accuracy: Reduces false positives and false negatives through consistent, repeatable inspections.

- Speed: Inspects hundreds of parts per minute—much faster than any human could manage.

- Non-Contact & Non-Destructive: Ensures products remain untouched and unharmed during inspection.

- Scalability: Easily adapts to different product lines and inspection requirements.

- Data-Driven Insights: Helps identify trends in defects, enabling root cause analysis and continuous improvement.

- Cost Efficiency: Reduces labor costs and waste from over-rejection or under-detection.

Applications Across Industries

Machine Vision AI is widely used across industries to accurately detect and count defects, ensuring high quality and reducing waste:

- Electronics: Counts solder joint defects and missing components on PCBs.

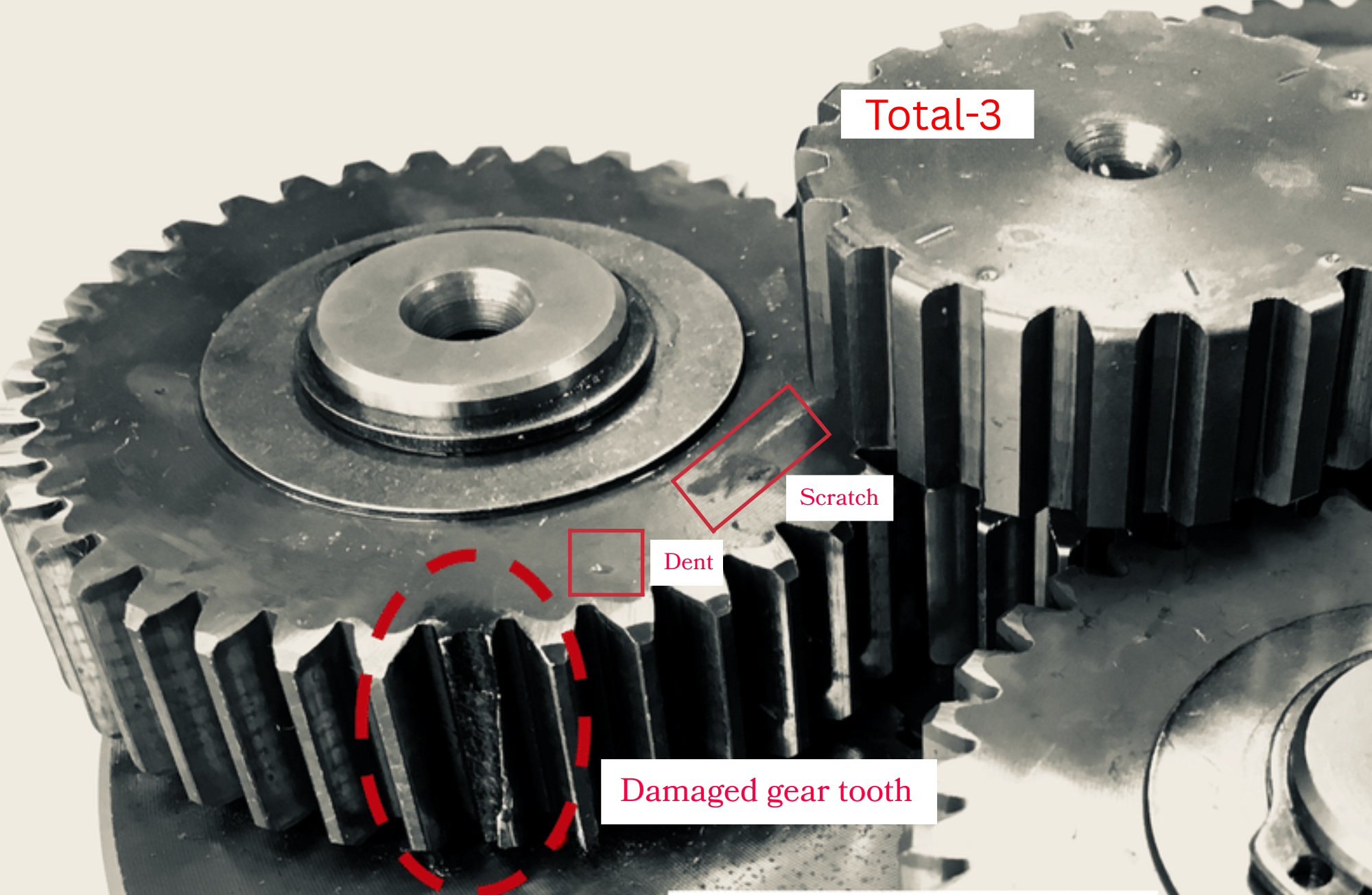

- Automotive: Detects and counts surface scratches, dents, and weld flaws on metal parts.

- Wood Industry: Identifies and counts knots, cracks, and stains for panel grading (e.g., Intelgic’s Live Vision).

- Packaging: Counts label misalignments, seal breaks, and foreign contaminants.

- Textile: Detects and counts pattern irregularities, thread pulls, and color inconsistencies.

- Pharmaceutical: Counts missing pills, packaging defects, and labeling errors for regulatory compliance.

- Lens Industry: Detects and counts defects such as scratches, bubbles, and surface irregularities to ensure optical clarity and safety.

Intelgic: Pioneering the Future of Automated Defect Counting

Intelgic stands at the cutting edge of industrial automation, delivering advanced solutions like Live Vision—a powerful machine vision platform designed to meet the evolving demands of quality control. By integrating sophisticated AI algorithms, high-resolution imaging, and adaptable inspection modules, the platform enables precise, real-time, and scalable defect counting across diverse manufacturing settings.

From wooden panel inspections to electronics and customized applications, Intelgic’s technology facilitates automated inspections, minimizes production downtime, and elevates product quality—all without the need for manual intervention.

With continuous innovation and commitment to excellence, Intelgic is shaping the future of defect detection and counting, helping industries achieve higher standards of efficiency, accuracy, and reliability.