Achieving Accurate Pipe Circumference Measurement using Machine Vision AI

Published on: Apr 17, 2025

Written by: Content team, Intelgic

Achieving Accurate Pipe Circumference Measurement using Machine Vision AI

Pipes are foundational components across a wide range of industries—from oil and gas to construction, pharmaceuticals, automotive, and food processing. They vary in material, diameter, wall thickness, and finish, depending on their application. Whether it's a small stainless steel pipe in a dairy plant or a large steel pipeline transporting crude oil, the accurate measurement of pipe circumference is critical for quality assurance, safety, and compliance.

As manufacturing lines grow increasingly automated and complex, measuring the circumferences of pipes in real time becomes not only a challenge but a vital requirement. Inaccurate measurements can lead to product rejections, leakage, equipment failure, or costly rework. Fortunately, With advancements in machine vision and artificial intelligence (AI), manufacturers can now achieve real-time, high-precision measurements with minimal manual intervention.

Why Accurate Pipe Circumference Measurement Is Crucial

Pipes are not just conduits for fluids or gases—they are engineered components that must meet exact specifications. The outer circumference of a pipe directly relates to its diameter and overall fit in the system it is designed for.Pipes of different sizes and materials are used in a wide variety of industries. Whether it’s a 3-inch stainless steel pipe used in a food-grade system or a 24-inch carbon steel pipe in oil pipelines, measuring the pipe's circumference accurately is essential to:

- Ensure proper fit and sealing during assembly

- Maintain flow rate consistency and pressure integrity

- Guarantee system safety, especially in high-pressure or hazardous environments

- Meet quality control standards and regulatory requirements

- Eliminate downtime, rework, and waste due to incorrect dimensions

Challenges of Measuring Circumferences of Pipes in Manufacturing

Measuring the outer circumference of cylindrical objects like pipes may seem simple, but in manufacturing environments, it presents a host of challenges:

- High-Speed Production Lines

Pipes move quickly along conveyor belts, leaving little time for manual or slow measurement techniques. Stopping production for inspection can result in costly downtime.

- Variations in Pipe Dimensions

Different pipe batches often vary in diameter and wall thickness due to material expansion, shrinkage, or manufacturing tolerances, making it hard to maintain consistency.

- Surface Finish and Reflectivity

Metallic or coated pipes often reflect light irregularly, affecting the accuracy of traditional optical measurement systems.

- Environmental Conditions

Industrial environments are prone to dust, vibrations, and temperature fluctuations, which can affect sensor performance and accuracy.

- Human Error and Inconsistency

Manual tools like calipers or measuring tapes are prone to errors and inconsistencies between operators, especially when dealing with large volumes or non-standard pipe sizes.

The Role of Area Scan Cameras and Backlight & AI Software in Circumference Measurement

To overcome these challenges, machine vision systems equipped with area scan cameras and backlighting techniques have emerged as a highly effective solution.

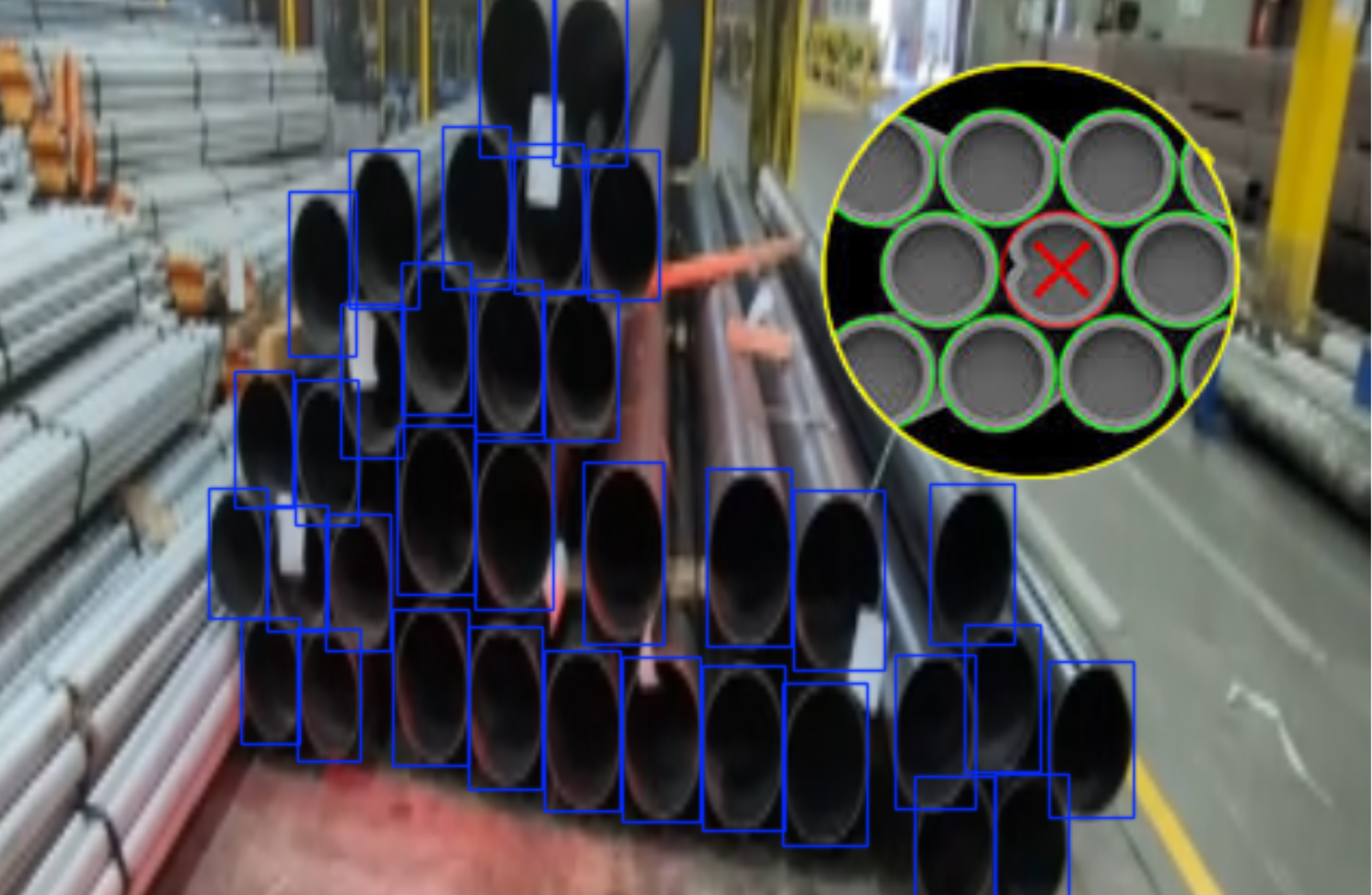

Area Scan Cameras

An area scan camera is designed to capture a full 2D image of the pipe’s surface or cross-sectional profile in a single frame. When measuring the circumference of pipes, this type of camera provides high-resolution imaging that enables precise edge detection and accurate dimensional analysis. By capturing the entire field of view at once, it delivers consistent and reliable measurements, especially useful when the pipe is stationary or indexed during inspection. The camera works in tandem with a calibrated backlighting setup to enhance contrast, allowing the system to clearly define the outer boundaries of the pipe for precise circumference calculations.

In circumference measurement:

- The camera is positioned to capture a cross-sectional view or a side profile of the pipe.

- It records detailed images where edges, curves, and outlines are visible with high clarity.

- These images are analyzed by AI software to detect the pipe’s outer diameter and calculate the circumference using geometric algorithms.

High-resolution sensors in area scan cameras ensure that even micro-deviations or ovalities in the pipe profile are detected—something manual measurement cannot achieve consistently.

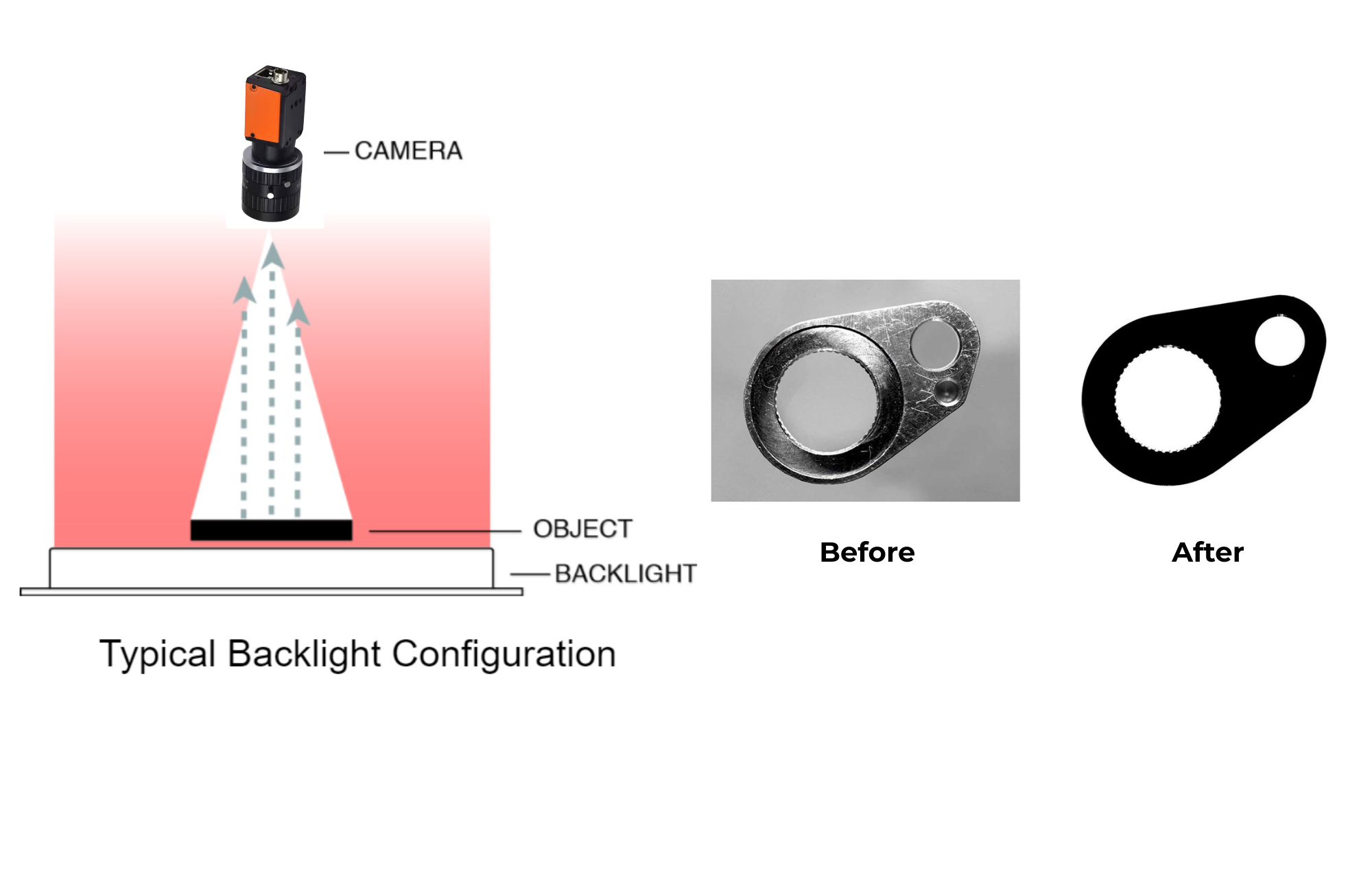

Backlight Illumination

Backlighting involves positioning a uniform, high-intensity LED light source directly behind the pipe during inspection. This technique creates a strong contrast between the illuminated background and the pipe’s outer edges, producing a crisp and well-defined silhouette. When paired with an area scan camera, backlighting enables the system to precisely detect the pipe's contours, regardless of surface texture or finish.

This method is especially effective for:

- Highlighting the exact outer boundary of the pipe, ensuring accurate circumference measurement.

- Eliminating interference from surface defects, such as scratches, weld seams, rust, or oil residue.

- Maintaining clarity even when working with highly reflective metals, matte coatings, dark surfaces, or uneven finishes.

AI Software for Real-Time Measurement

The real magic happens when machine vision hardwares are paired with AI-driven software, which adds intelligence, adaptability, and speed to the inspection process. Here’s how AI software enables real-time pipe circumference measurement:

- Edge Detection and Contour Analysis

AI-powered vision models can be trained to detect pipe edges precisely, even in noisy or low-contrast conditions. They can adapt to different pipe materials and finishes.

- Real-Time Processing

Using powerful embedded processors or edge AI modules, the system can process images instantly, delivering live measurements without interrupting production.

- Automated Calibration and Adjustment

The AI software auto-calibrates for variations in camera distance, lighting, or pipe positioning, ensuring consistent accuracy.

- Anomaly Detection

The system can flag defects like ovality (out-of-round pipes), surface cracks, or inconsistent diameters in real time.

- Cloud Integration and Analytics

Measured data can be logged, stored, and analyzed over time for quality control, predictive maintenance, and process optimization.

AI-Powered Workflow for Accurate Pipe Circumference Measurement

1. Pipe Enters the Inspection Zone

The pipe moves along a conveyor or automated system, positioning itself within the field of view of the machine vision system. This ensures each pipe is properly aligned for precise measurement.

2. Backlighting Activation

A high-intensity LED backlight is activated behind or beneath the pipe, creating a stark contrast. The backlighting illuminates the pipe’s edges clearly, forming a sharp silhouette that enhances the accuracy of subsequent image capture.

3. Image Capture via Area Scan Camera

The area scan camera captures a full 2D image of the pipe’s profile. The camera’s high-resolution capabilities ensure clear, detailed images, even with complex surfaces, coatings, or irregular shapes.

4. AI-Powered Image Analysis

The captured image is processed in real-time by AI-driven software to:

- Detect the pipe’s edges with high accuracy.

- Calculate the pipe’s diameter and circumference using advanced geometric algorithms.

- Compare the measured dimensions with pre-set tolerance thresholds to determine if the pipe is within specification.

5. Result Output and Action

The measurement results are displayed on a screen or logged in the system for immediate review. If the pipe is out of spec:

- The pipe is flagged or automatically diverted from the production line.

- Alerts are sent to quality control or plant operators, ensuring immediate corrective action.

6. Data Logging and Reporting

All measurement data is stored securely for traceability, enabling full performance monitoring. Reports are automatically generated for regulatory compliance, audit readiness, and ongoing process optimization.

Benefits of AI-Powered Machine Vision Systems for Measuring Pipe Circumferences

Adopting AI-based vision systems for circumference measurement offers numerous benefits:

- High Accuracy: AI software delivers sub-millimeter precision, detecting even the slightest deviation in circumference or pipe shape.

- Fast and Scalable: Whether inspecting small tubes or large pipelines, the system keeps up with production without bottlenecks.

- Non-Contact, Non-Invasive:There’s no physical contact with the pipe—eliminating surface damage and reducing maintenance needs.

- Adaptability Across Sizes: With adjustable camera positioning and AI reconfiguration, the system handles different pipe diameters with ease.

- Real-Time Monitoring and Alerts: Instant feedback helps operators take corrective actions on the spot, reducing scrap and rework.

- Compliance-Ready: Automated reporting ensures easy compliance with ISO, FDA, and other industry standards.

- Integration with Industrial Systems: Connect seamlessly with SCADA, MES, and ERP systems for end-to-end digital manufacturing.

Applications in Key Industries

1. Oil & Gas :Transporting crude oil, natural gas, and petroleum products through pipelines.

2. Automotive & Aerospace: Fuel lines, brake systems, exhaust pipes, hydraulic tubes, and cooling systems.

3. Construction & Infrastructure: Plumbing, HVAC systems, structural piping, drainage, and fire protection.

4. Food & Beverage: Sanitary piping for transferring liquids, syrups, dairy, and gases.

5. Pharmaceutical: Fluid transfer, sterile piping systems, and cleanroom manufacturing environments.

6. Chemical & Water Treatment : Supply lines, drainage, sewage systems, and filtration infrastructure.

7. Energy & Power Generation : Steam lines, cooling systems, boiler tubes, and condenser piping.

How Intelgic Stands Out

Intelgic brings a unique edge to the machine vision landscape with its Live Vision AI platform—a smart inspection solution designed specifically for real-time industrial measurement and defect detection.

Here’s how Intelgic stands out in pipe circumference measurement:

- Tailored AI Models

Intelgic develops customized AI models specifically trained on diverse pipe datasets. This ensures high adaptability to various sizes, shapes, and surface textures.

- Edge AI Deployment

Live Vision is designed for on-premise processing, minimizing latency and enabling decisions in milliseconds without relying on cloud speed.

- Modular Hardware Compatibility

The platform supports a wide range of area scan cameras, industrial lenses, and illumination options, making it easy to integrate into existing infrastructure.

- Dynamic Calibration Engine

Intelgic’s auto-calibration technology compensates for environmental variables like light drift, vibrations, or camera angle shifts in real time.

- Multi-Point Measurement Capability

Intelgic’s system can measure not just one, but multiple circumferences or diameters across different sections of the same pipe—providing a comprehensive profile.

- Advanced Reporting & Analytics

With intuitive dashboards, alerts, and historical data logs, Intelgic enables manufacturers to maintain full visibility of their quality metrics.

- Easy Integration with MES/SCADA Systems

Intelgic seamlessly integrates with existing production systems, ensuring a smooth digital workflow without disrupting operations.

In an era where manufacturing is increasingly data-driven and precision-focused, automating the measurement of pipe circumferences is no longer optional—it’s a necessity. Traditional methods can no longer keep pace with the demands of speed, scale, and accuracy.

Thanks to innovations in machine vision, area scan imaging, backlighting, and AI software, manufacturers can now perform real-time, non-contact, and highly accurate measurements without slowing down production. Among the leaders in this transformation, Intelgic provides a smart, scalable, and adaptable solution that not only measures but enhances overall production efficiency.

For manufacturers looking to modernize their inspection systems, reduce error rates, and ensure top-tier quality, Intelgic's AI-powered vision platform is a game-changer.